Website:

UNIVER Group

Website:

UNIVER Group

Catalog excerpts

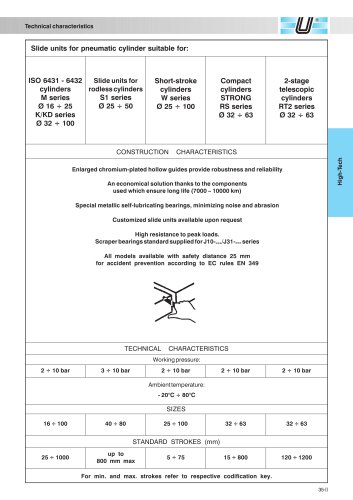

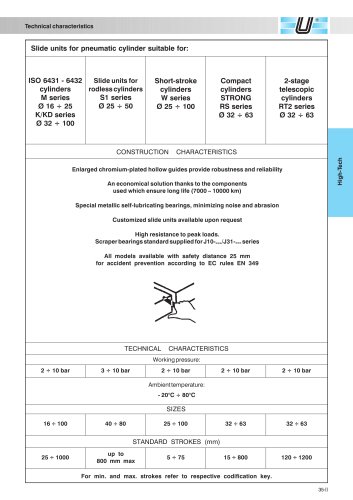

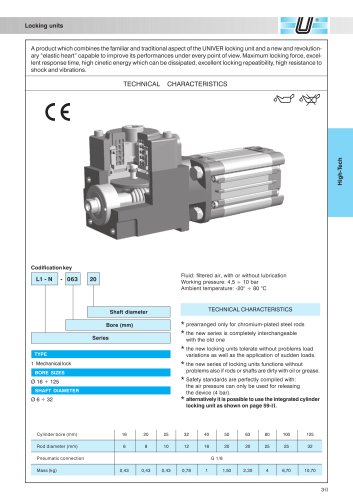

Locking units A product which combines the familiar and traditional aspect of the UNIVER locking unit and a new and revolution- ary "elastic heart" capable to improve its performances under every point of view. Maximum locking force, excel- lent response time, high cinetic energy which can be dissipated, excellent locking repeatibility, high resistance to TECHNICAL CHARACTERISTICS Shaft diameter BORE SIZES SHAFT DIAMETER Fluid: filtered air, with or without lubrication TECHNICAL CHARACTERISTICS * prearranged only for chromium-plated steel rods * the new series is completely interchangeable...

Open the catalog to page 2

Technical characteristics A spring in special steel, developed together with FEA (Finite Element Analysis) and with the assistance of the most advanced CAD technics, constitutes the heart of this new locking unit which, in addition to the excellent locking capacity and repeatibility, enable a soft braking of the moved masses. Main performances and characteristics: * For release pressure values under 4 bar, the reaction of the locking unit cannot be foreseen. Braking distance In some applications, it could be necessary to know the piston rod stroke between the reception of an emergency This...

Open the catalog to page 3

Locking units for 0 16 - 20 - 25 mm ISO microcylinders Additional length to the standard rod Locking unit for compact cylinders STRONG 0 32 - 63 mm Fixing screws Additional length to standard rod with ISO protrusion

Open the catalog to page 4

Locking units for ISO cylinders 0 32 + 125 Reduced protrusion Pneumatic lock Additional length to the standard rod Screw with hexagonal head UNI 5739 and washer UNI 6592 for assembling locking unit to ISO .other examples of locking unit applications Chromium-plated shaft

Open the catalog to page 5

L6 series locking unit for rodless cylinders Locking unit The UNIVER locking unit for rodless cylinders has been realized with the aim to stop the carriage in any point of its stroke and it is able to provide a good locking precision. It is possible to assemble it indifferently on either side of the carriage and its mechanical braking force may be further amplified by means of an additional pneumatic control. Fluid: filtered air, with or without lubrification Locking unit for S5 series Manual release Maximum locking force (N) Locking unit for VL1 series Manual release Maximum locking force...

Open the catalog to page 6

Locking unit for S5 series Stroke Locking Fixing dimensions Locking unit for VL1 series Stroke Locking Fixing dimensions

Open the catalog to page 7

The original UNIVER rodless cylinder, the most versatile range for solving the problems of automation and positioning control S1 . . . with single chamber Extruded profile in aluminium Ø 16 ÷ 50 mm. Stroke to 5 m. Various supply port configurations available. Various carriage types. High translation speed 1 ÷ 3 m/s. Series S5 . . . with integrated guides Series VL1 Extruded profile in aluminium Ø 25 ÷ 50 mm. Stroke to 6 m. Flexible bearing system. Plastic bearings reduce noise. Translation speed 0,2 ÷ 1,5 m/s. Available with locking unit. . . . with integrated guides 90° Extruded profile in...

Open the catalog to page 8

Fluid: filtered air, with or without lubrication Standard strokes: up to 5 meters (0 16 mm) Min. speed required for regular translation: 7 20 mm/s. Carriage types: standard, medium, long, double medium Integrated guides: S5 series: round steel shafts VL1 series: steel foils at 90° External carriage slide: S5 series: with plastic sliding shoes VL1 series:with ball bearings Upon request - Magnetic version for S1 series (except for 0 16 magnetic version standard); for S5 series a special magnetic sensor holder extrusion DKS series is foreseen (section accessories page 6- ). - Magnetic sensor...

Open the catalog to page 9

Technical characteristics Examination and verification of the cushioning In a system with moving masses, as in the case of rodless cylinders, it is essential to control the dissipation of the system's kinetic energy as it is brought to a stop. It is necessary, first of all, to establish and verify the most suitable method of cushioning the system, in order to avoid the moving mass (carriage with load) striking against the end-caps and compromising the life of the cylinder. If the point corresponding to a given load and speed lies beneath the appropriate curve, the cushioning is able to...

Open the catalog to page 10

If it is not possible to absorb the kinetic energy with the cushioned end-caps and modify the parameters (a-b-c shown at page 11), an additional cushioning is necessary to reduce the load speed before the cylinder strikes the - a pneumatic cushion with electronic control; - a hydraulic cushion, available on the market. The mass movement generates loads to the cylinder, connected both to the weight forces (load values are constant) and to the inertia forces which originate in the acceleration or deceleration phases of the piston at the A typical fatigue stress arises in which the load value...

Open the catalog to page 11

Codification key for rodless cylinders "S" Series 0 16 -s- 50 mm Right end-cap supply port (dx) Left end-cap supply port (sx) Carriage type S5 = Integrated guides/plastic bearings CARRIAGE TYPE LEFT END-CAP SUPPLY PORT 0 = No supply port (when both chambers are supplied from the right end-cap) 1 = Side supply port * 2 = Bottom supply port * 3 = Rear supply port * RIGHT END-CAP SUPPLY PORT 1 = Side supply port (twin 0 16 mm) 2 = Bottom supply port * 3 = Rear supply port (twin 0 16 mm) 4 = Both chambers supplied from the right end-cap BORE SIZE M = Magnetic version standard for 0 16 mm, upon...

Open the catalog to page 12

Rodless cylinders with standard carriage - 6 fixing holes cushion needles Mass (kg) Weight increase (kg) per Cyl0 AU AV AW AX AY AZ_at "0" stroke_additional 100 mm stroke

Open the catalog to page 13

Values of the static load; please note that under dynamic conditions the load must be reduced due to the effects associated with the speed. The torque is the prod uct of load (Newton) per arm (meters), i.e. the distance between the center of gravity of the load and the longitudinal axis of the piston (technical characteristics see page 11-12- ). Bending moment Bending moment Standard carriage Medium carriage Long carriage ♦ It is not advisable to use the cylinder in applications with high stress. Medium carriage - 6 fixing holes for cylinders 0 25 4- 50 mm Long carriage -10 fixing holes for...

Open the catalog to page 14All UNIVER Group catalogs and technical brochures

-

JLE

5 Pages

-

HZRS

2 Pages

-

MP Clamping cylinders

3 Pages

-

AC-N NAMUR valve

2 Pages

-

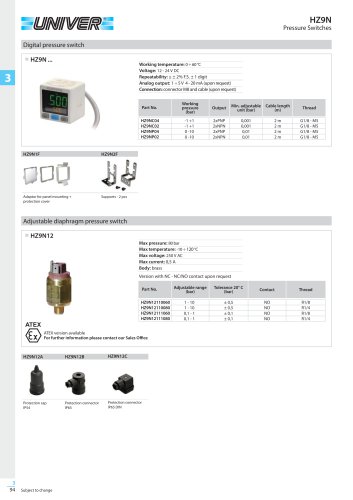

HZ9N

1 Pages

-

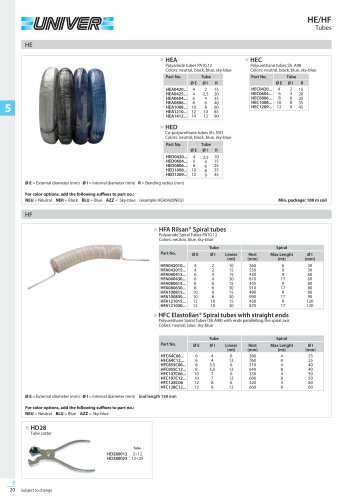

HE/HF tubes

1 Pages

-

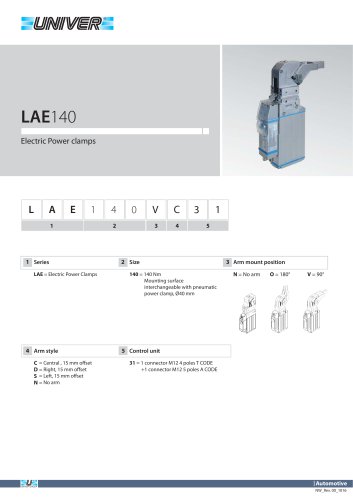

LAE140 Electric power clamps

4 Pages

-

Modular Tooling System - GR8

52 Pages

-

PRODUCT RANGE

44 Pages

-

ATEX PRODUCT RANGE

14 Pages

-

NEWS 2017-2018

32 Pages

-

NEWS 2016

16 Pages

-

PRODUCT OVERVIEW

228 Pages

-

Product range

44 Pages

-

ATEX Certified products

14 Pages

-

NEWS 2017

32 Pages

-

Valves

210 Pages

-

UBH40_UNIVERSAL Power clamps

6 Pages

-

PRODUCT RANGE

32 Pages

-

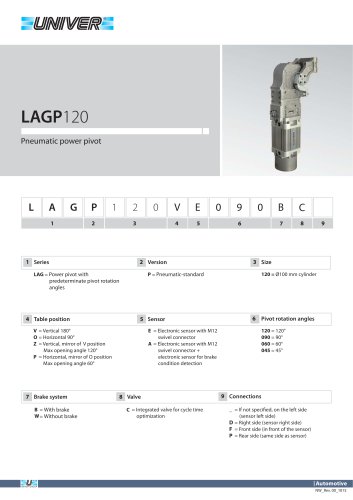

LAGP605_Pneumatic power pivot

13 Pages

-

LAGP600_Pneumatic power pivot

13 Pages

-

LAGP350_Pneumatic power pivot

13 Pages

-

LAGP300_Pneumatic power pivot

13 Pages

-

LAGP210_Pneumatic power pivot

13 Pages

-

LAGP170_Pneumatic power pivot

13 Pages

-

LAGP155_Pneumatic power pivot

13 Pages

-

LAGP150_Pneumatic power pivot

13 Pages

-

LAGP120_Pneumatic power pivot

13 Pages

-

LAGP080_Pneumatic power pivot

13 Pages

-

LAGP075_Pneumatic power pivot

13 Pages

-

PRP1100_Marking units

3 Pages

-

PRP0500_Marking Units

4 Pages

-

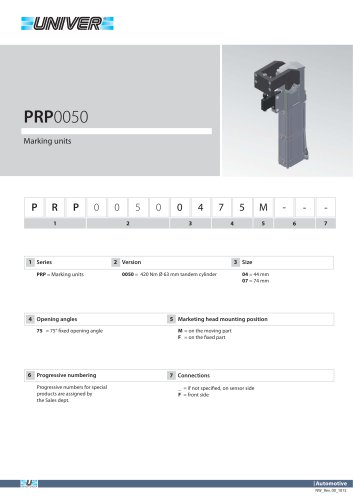

PRP0050_Marking units

3 Pages

-

PRP0025_Marking units

2 Pages

-

LGP40_ Pneumatic Grippers

7 Pages

-

LGP32_ Pneumatic Grippers

7 Pages

-

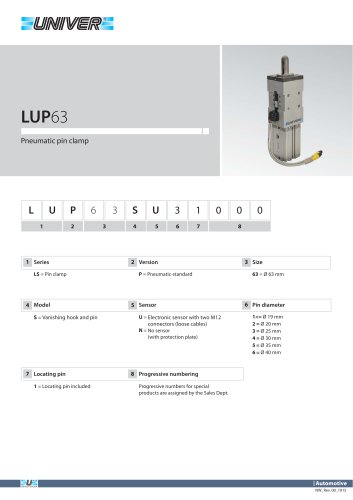

LUP63_Pneumatic pin clamp

2 Pages

-

LSP60_Pneumatic pin clamp

3 Pages

-

LSP50U_Pneumatic pin clamp

3 Pages

-

LSP32_Pneumatic pin clamp

3 Pages

-

IBM40_UNIVERSAL Power clamps

6 Pages

-

IBP40_UNIVERSAL Power clamps

6 Pages

-

UBH63_UNIVERSAL Power clamps

6 Pages

-

UBM40_UNIVERSAL Power clamps

6 Pages

-

UBM50_UNIVERSAL Power clamps

10 Pages

-

UBM63_UNIVERSAL Power clamps

10 Pages

-

UBM80_UNIVERSAL Power clamps

10 Pages

-

UBP32_UNIVERSAL Power clamps

4 Pages

-

UBP50_UNIVERSAL Power clamps

6 Pages

-

UBP63_UNIVERSAL Power clamps

6 Pages

-

UBP80_UNIVERSAL Power clamps

8 Pages

-

UBQ40_UNIVERSAL Power clamps

8 Pages

-

UBQ63_UNIVERSAL Power clamps

6 Pages

-

UBT40_UNIVERSAL Power clamps

6 Pages

-

AUTOMOTIVE DIVISION

24 Pages

-

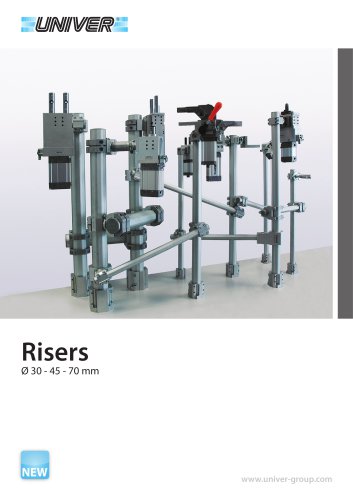

RISERS

4 Pages

-

LGP32-40 Pneumatic Grippers

16 Pages

-

GR8-Modular Tooling System

44 Pages

-

M series

1 Pages

-

Product Overview

228 Pages

-

POWER PIVOTS

2 Pages

-

PIN CLAMPS

2 Pages

-

CLAMPS

2 Pages

-

ACCESSORIES

54 Pages

-

AIR TREATMENT

14 Pages

-

CYLINDERS

67 Pages

-

KE_Cylinders according to ISO 15552

10 Pages

-

HZE_Additional components

4 Pages

-

HZE_Air treatment units

14 Pages

-

L1/L6_Locking unit for cylinders

6 Pages

-

HZE_Air treatment units

12 Pages

-

fittings

36 Pages

-

PS_COMBOBOX valves

12 Pages

-

AI_Miniature limit switches

4 Pages

-

CH_2/2 - 3/2 G1/8 poppet valves

4 Pages

-

A_15 mm Microvalves

6 Pages

-

B10_Nanovalvole 10 mm ISO 15218

2 Pages

-

OV_Oval cylinders Ø 18-80 mm

5 Pages

-

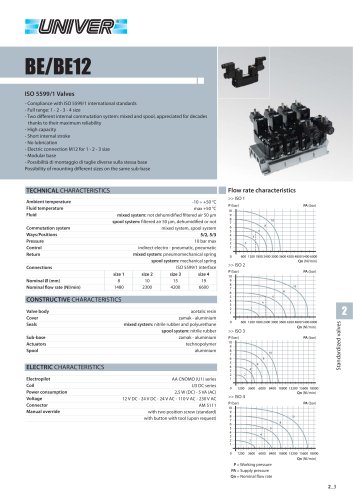

BE/BE12_ISO 5599/1 Valves

12 Pages

-

Rodless cylinders Ø 16-50 mm

12 Pages

-

Rotary actuators Ø 32-125 mm

3 Pages