Website:

Tuthill

Website:

Tuthill

Group: Tuthill Corporation

Catalog excerpts

Mechanical Booster Vacuum Syste

Open the catalog to page 1

Kinney Mechanical Booster/Rotary Vacuum Boosters Provide Lower Pressures When system pressure is brought to a preset level by the Piston Pump, the high capacity booster cuts in to reduce pressure rapidly. Piston Pump provides initial pumpdown to preset cut-in A Piston Pump and a high capacity booster combination achieves both lower pressures and higher capacities than a single vacuum pump. With the exception of close-coupled systems, the pump and the booster are run by separate motors. Initial pumpdown is accomplished by the vacuum pump, and the pressure sw itch is activated to start the...

Open the catalog to page 2

Piston Vacuum Pumping Systems Standard Mechanical Booster Vacuum Pumping Systems which combine Rotary Piston Vacuum Pumps and KMBD Mechanical Boosters are available in capacities from 221 cfm to 10,450 cfm and for vacuum levels below 1 micron. These systems provide all of the advantages of Kinney Rotary Piston Pumps, including quiet, vibration-free operation, long life due to the elimination the pumping chamber, forced lubrication for constant oil flow at all pressures, high vapor han- dling capability, recommended where wide desirable, capacities over Low profile KT Pumps are used in...

Open the catalog to page 3

Rotary Piston Pump/Booster -Standard Systems Rotary Piston Pump/Booster-Compact Systems

Open the catalog to page 4

*Call Kinney for variable operating pressures. Rotary Piston Pump/Booster-Close-Coupled Systems

Open the catalog to page 5

Kinney Mechanical Booster Liquid Lower Pressures, Higher Capacities with Virtually any Process Gas Liquid Ring Pump/Booster Systems These systems are most effective for relatively large capacity (to 10,000 din), partly wet gas mixtures at intermediate to high vacuum and where corrosion or compatible sealants may be a problem. Liquid Ring Pump/Air Ejector/ Booster Systems These systems provide significantly lower continuous operating pressures. With air ejectors, liquid ring pump performance is less sensitive to sealant properties and can lower the booster discharge pressure. Air ejectors...

Open the catalog to page 6

Vacuum Pumping Systems Booster System These systems are most effective for relatively large capacity (to 10,000 cfm), partly wet gas mixtures at intermediate to high vacuum and where corrosion or compatible sealants Kinney multiple-stage vacuum pumping systems consist ofliquid ring vacuum pumps in combination with lobe- type mechanical boosters and air ejectors. These sys- tems offer the advantages ofliquid ring pump design with much higher pumping speeds and lower pressures than can be achieved with single-stage systems. Kinney multiple-stage liquid ring pumping systems are particularly...

Open the catalog to page 7

Liquid Ring/Booster Pump - Standard Systems Note: Shown below are specifications and dimensions for the most popular systems. Many other combinations are also available. Consult your Kinney representative or the factory for information and assistance. Liquid Ring/Interstage Ejector/Booster Pump - Standard Systems 1) Rated pumping speed at 26"Hg 2) Ultimate pressure dependant on sealant fluid and temperature I) Rating for no sealant recovery system 4) Only for OFRP system Kinney Vacuum

Open the catalog to page 8All Tuthill catalogs and technical brochures

-

D, T, & P Series

14 Pages

-

HD Series Pumps

39 Pages

-

4000 Series Pumps

18 Pages

-

1008 & 1010 Size Pumps

9 Pages

-

Product Line Brochure

6 Pages

-

D, T, & P SERIES

6 Pages

-

GlobalGear® Series

6 Pages

-

Heavy Duty Series

6 Pages

-

Tuthill Plastic Group

6 Pages

-

D Series Pump

3 Pages

-

Performance Curves - 1000 Series

16 Pages

-

Engineering Data Pack - M Series

23 Pages

-

FR1118P10 In-line Meter

1 Pages

-

Tuthill Precision Meters

8 Pages

-

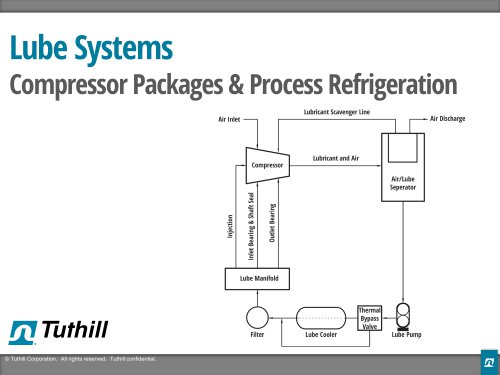

Presentation - Lube Systems

9 Pages

-

L & C SERIES

6 Pages

-

1000 SERIES

6 Pages

-

White Paper - Pulp & Paper

2 Pages

-

White Paper - Asphalt

3 Pages

-

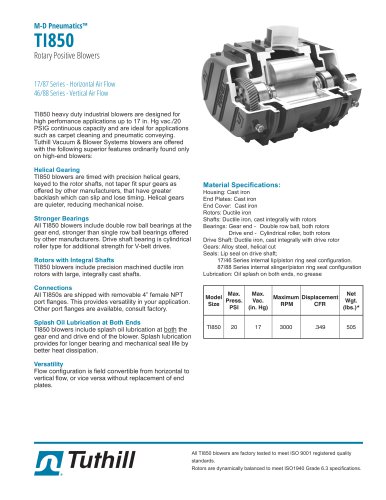

TI850 TH-063

2 Pages

-

QX TH-094

2 Pages

-

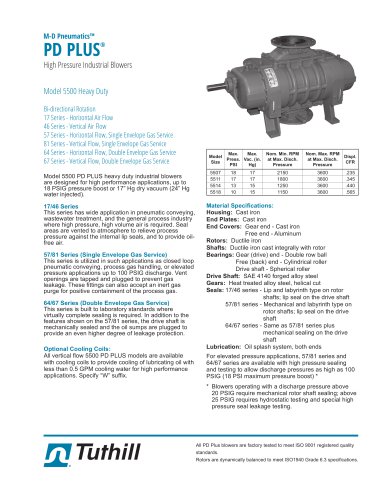

PD Plus 9000 TH-052

2 Pages

-

PD Plus 7000 TH-051

2 Pages

-

PD Plus 5500 TH-050

2 Pages

-

PD Plus 3200 TH-048

2 Pages

-

PD Plus 1200 TH-047

2 Pages

-

MD Pneumatics blower

2 Pages

-

PneuPak TH-056

2 Pages

-

PneuMax II TH-055

2 Pages

-

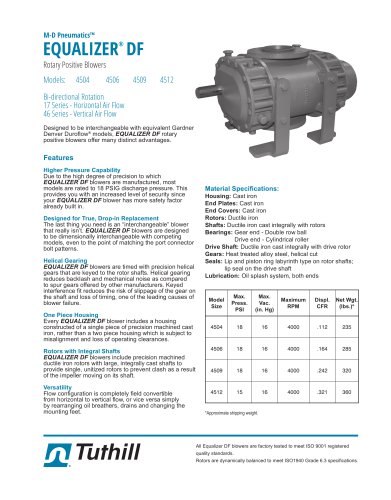

Equalizer RM TH-045

2 Pages

-

Equalizer DF TH-046

2 Pages

-

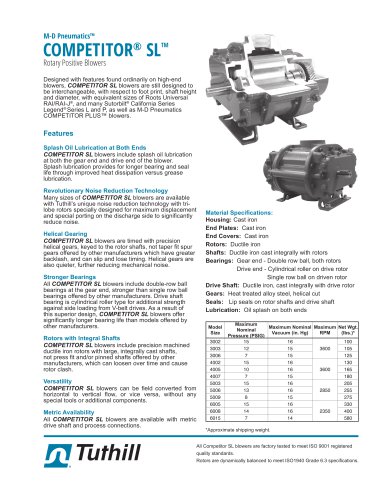

Competitor SL TH-044

2 Pages

-

Competitor Plus TH-043

2 Pages

-

TuffSeall

2 Pages

-

M Series

2 Pages

-

HD Series

6 Pages

-

Full Line

6 Pages

-

Vacuum Pumps Brochure TH-004

8 Pages

-

atlantic fluidics

16 Pages

-

KDS Dry Screw Vacuum Pump

3 Pages

-

Vacuum Pump Selector Guide

6 Pages

-

KTLP/VFP Series

2 Pages

-

Kinney® KMBD Vacuum Boosters

2 Pages

-

Liquid Ring Vacuum Pumps

16 Pages

-

Rotary Piston Vacuum Pumps

18 Pages

-

Process Gear pumps

6 Pages

-

T950H Brochure

4 Pages

-

T650 Product Brochure

4 Pages

-

Qube Product Brochure

6 Pages

Archived catalogs

-

Heavy Duty Series

6 Pages

-

GlobalGear® Series

6 Pages

-

D, T, & P SERIES

6 Pages

-

D, T, & P Series

14 Pages

-

Series 1000

6 Pages

-

T850/T1050 Truck Blowers

4 Pages