Website:

Tuthill

Website:

Tuthill

Group: Tuthill Corporation

Catalog excerpts

KINNEY® KMBD™ Mechanical Boosters Mechanical boosters are used to “supercharge” vacuum pumps to greatly extend pump performance. This allows for much faster pumping speeds and deeper vacuum levels. KMDB mechanical boosters from Tuthill Vacuum & Blower Systems are utilized worldwide in the manufacture of chemicals, petrochemicals, plastics, semiconductors and wood composites as well as food processing, vacuum furnace applications and many other general applications in industry. Optional Materials and Coatings Available Standard construction materials include cast iron housing, end plates and port fittings with ductile iron rotors and shafts. In addition to standard construction, the following materials are available: Special Materials Ductile Iron Steel Stainless Steel Hastelloy® Special Coatings Armoloy® electrochromium Nickel Ryton® polyphenylene sulfide (PPS) Low Mechanical Noise Every KMBD mechanical booster is designed to operate at 82 dB(A) or less at blank-off (open field; motor and background noise excluded) Versatile Drive Configurations KMBD Mechanical Boosters are supplied with a heavy-duty drive shaft for either direct coupled or belt-driven applications. Material Specifications Housing: End Plates: End Covers: Rotors: Shafts: Drive Shaft: Cast iron Cast iron Cast iron Ductile iron Ductile iron cast integrally with rotors KMBD 200/400 - Ductile iron All others - SAE 4140 forged alloy steel Bearings: Gear end - All models: Double row ball, both rotors Back end - KMBD 200/400 – 4500: Cylindrical roller KMBD 5500 – 10000: Double row ball Drive Shaft: KMBD 200/400 – 720: Double row ball KMBD 850 – 2700: Single row ball KMBD 2900 – 4500: Cylindrical roller KMBD 5500 – 10000: Spherical roller Gears: Heat-treated alloy steel, helical cut & precision ground Seals: Drive shaft – Mechanical Rotor shafts – Non-contacting slinger (Mechanical seals optional) Lubrication: KMBD 200/400 – 2700: Oil splash system, both ends KMBD 2900 – 7300: Oil splash system standard, Integral pressure lube optional KMBD 800 – 10000: Integral pressure lube standard Water-cooled End Plates All vertical flow KMBD 200/400 – 2700 models are available with Tuthill Vacuum & Blower Systems’ exclusive optional water cooled end plates to provide cooling of lubricating oil with 0.11.0 GPM (0.4-4.0 L/min) cooling water for high performance applications. Specify “E” suffix. All KMBD 2900 – 4500 models with either vertical or horizontal flow are supplied with water-cooled end plates as standard. Advantages of water-cooled end plates include: • Reduced oil vapor back-streaming • Lower mechanical noise • Higher allowable cut-in points • Lower discharge temperatures • Increased pumping speed • Higher staging ratios • Extended oil, bearing, gear and seal life Optional Motor Mounting Flanges All KMBD 200/400 – 4500 models are available with flange adapters for mounting either a NEMA C-face motor (up to 75 HP) or an IEC D-flange motor (up to 55 kW) directly to the mechanical booster, eliminating the need for a separate base mounted assembly and coupling guard for the mechanical booster. Specify “C” suffix. Metric Availability All KMBD Mechanical Boosters are available with metric drive shaft and process connections. Individually Tested Every KMBD mechanical booster is fully factory run tested, including blank-off test and heat run to assure you of the highest quality. Tuthill Vacuum & Blower Systems goes the distance to insure that your mechanical booster meets our rigid ISO 9001 registered quality standards. Worldwide Sales and Service With sales offices and service facilities located on six continents, you can be assured of availability and service for your KMBD Mechanical Boosters.

Open the catalog to page 1All Tuthill catalogs and technical brochures

-

D, T, & P Series

14 Pages

-

HD Series Pumps

39 Pages

-

4000 Series Pumps

18 Pages

-

1008 & 1010 Size Pumps

9 Pages

-

Product Line Brochure

6 Pages

-

D, T, & P SERIES

6 Pages

-

GlobalGear® Series

6 Pages

-

Heavy Duty Series

6 Pages

-

Tuthill Plastic Group

6 Pages

-

D Series Pump

3 Pages

-

Performance Curves - 1000 Series

16 Pages

-

Engineering Data Pack - M Series

23 Pages

-

FR1118P10 In-line Meter

1 Pages

-

Tuthill Precision Meters

8 Pages

-

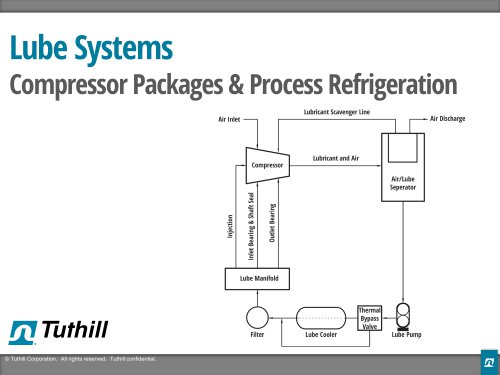

Presentation - Lube Systems

9 Pages

-

L & C SERIES

6 Pages

-

1000 SERIES

6 Pages

-

White Paper - Pulp & Paper

2 Pages

-

White Paper - Asphalt

3 Pages

-

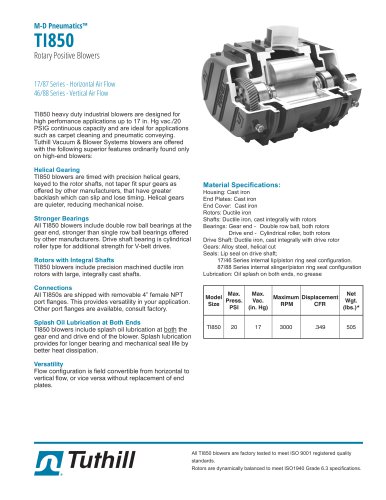

TI850 TH-063

2 Pages

-

QX TH-094

2 Pages

-

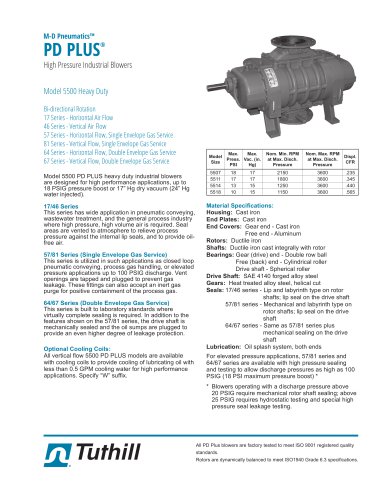

PD Plus 9000 TH-052

2 Pages

-

PD Plus 7000 TH-051

2 Pages

-

PD Plus 5500 TH-050

2 Pages

-

PD Plus 3200 TH-048

2 Pages

-

PD Plus 1200 TH-047

2 Pages

-

MD Pneumatics blower

2 Pages

-

PneuPak TH-056

2 Pages

-

PneuMax II TH-055

2 Pages

-

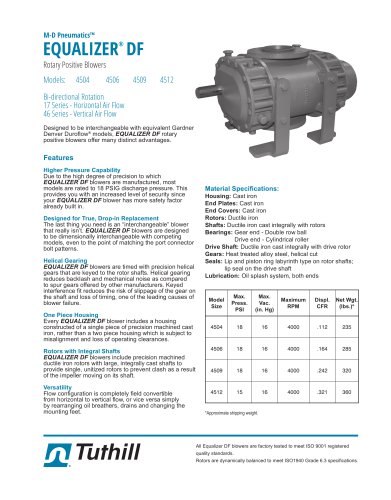

Equalizer RM TH-045

2 Pages

-

Equalizer DF TH-046

2 Pages

-

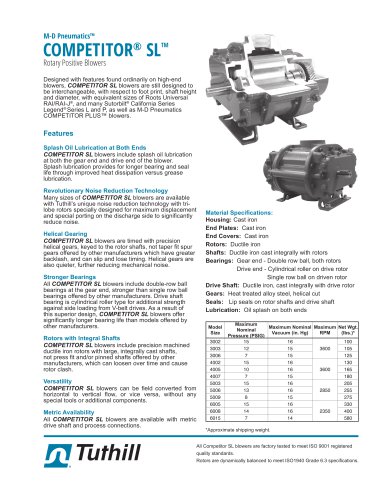

Competitor SL TH-044

2 Pages

-

Competitor Plus TH-043

2 Pages

-

TuffSeall

2 Pages

-

M Series

2 Pages

-

HD Series

6 Pages

-

Full Line

6 Pages

-

Vacuum Pumps Brochure TH-004

8 Pages

-

atlantic fluidics

16 Pages

-

KDS Dry Screw Vacuum Pump

3 Pages

-

Vacuum Pump Selector Guide

6 Pages

-

KTLP/VFP Series

2 Pages

-

Liquid Ring Vacuum Pumps

16 Pages

-

Rotary Piston Vacuum Pumps

18 Pages

-

Process Gear pumps

6 Pages

-

T950H Brochure

4 Pages

-

T650 Product Brochure

4 Pages

-

Qube Product Brochure

6 Pages

Archived catalogs

-

Heavy Duty Series

6 Pages

-

GlobalGear® Series

6 Pages

-

D, T, & P SERIES

6 Pages

-

D, T, & P Series

14 Pages

-

Series 1000

6 Pages

-

T850/T1050 Truck Blowers

4 Pages