Website:

TÜNKERS

Website:

TÜNKERS

Group: TÜNKERS & EXPERT-TÜNKERS

Catalog excerpts

EFS Pallet accumulating conveyor system System EXPERT-TÜNKERS EFS - EXPERT-TÜNKERS Conveying System 1

Open the catalog to page 1

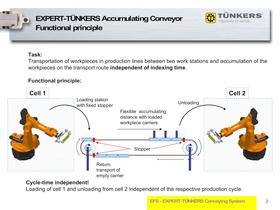

EXPERT-TÜNKERS Accumulating Conveyor Functional principle Task: Transportation of workpieces in production lines between two work stations and accumulation of the workpieces on the transport route independent of indexing time. Functional principle: Cell 1 Cell 2 Loading station with fixed stopper Unloading Flexible accumulating distance with loaded workpiece carriers Stopper Return transport of empty carrier Cycle-time independent! Loading of cell 1 and unloading from cell 2 independent of the respective production cycle. EFS - EXPERT-TÜNKERS Conveying System 2

Open the catalog to page 2

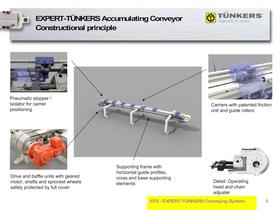

EXPERT-TÜNKERS Accumulating Conveyor Constructional principle Pneumatic stopper / isolator for carrier positioning Drive and baffle units with geared motor, shafts and sprocket wheels safely protected by full cover Carriers with patented friction unit and guide rollers Supporting frame with horizontal guide profiles, cross and base supporting elements Detail: Operating head and chain adjuster EFS - EXPERT-TÜNKERS Conveying System 3

Open the catalog to page 3

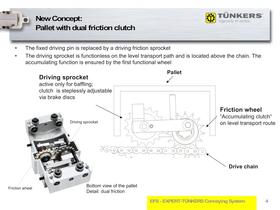

New Concept: Pallet with dual friction clutch • • The fixed driving pin is replaced by a driving friction sprocket The driving sprocket is functionless on the level transport path and is located above the chain. The accumulating function is ensured by the first functional wheel Driving sprocket Pallet active only for baffling; clutch is steplessly adjustable via brake discs Friction wheel Driving sprocket “Accumulating clutch“ on level transport route Drive chain Friction wheel Bottom view of the pallet Detail: dual friction EFS - EXPERT-TÜNKERS Conveying System 4

Open the catalog to page 4

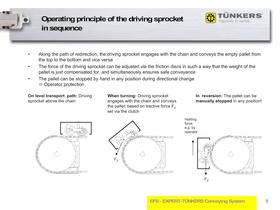

Operating principle of the driving sprocket in sequence • • • Along the path of redirection, the driving sprocket engages with the chain and conveys the empty pallet from the top to the bottom and vice versa The force of the driving sprocket can be adjusted via the friction discs in such a way that the weight of the pallet is just compensated for, and simultaneously ensures safe conveyance The pallet can be stopped by hand in any position during directional change Operator protection On level transport path: Driving sprocket above the chain When turning: Driving sprocket engages with the...

Open the catalog to page 5

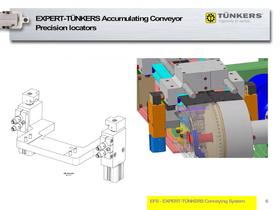

EXPERT-TÜNKERS Accumulating Conveyor Precision locators EFS - EXPERT-TÜNKERS Conveying System 6

Open the catalog to page 6

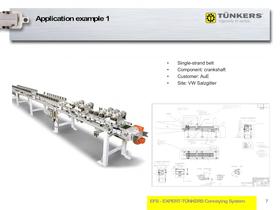

Application example 1 • • • • Single-strand belt Component: crankshaft Customer: AuE Site: VW Salzgitter EFS - EXPERT-TÜNKERS Conveying System 7

Open the catalog to page 7

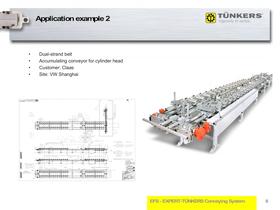

Application example 2 • • • • Dual-strand belt Accumulating conveyor for cylinder head Customer: Claas Site: VW Shanghai EFS - EXPERT-TÜNKERS Conveying System 8

Open the catalog to page 8

Application example 3 Accumulating conveyor 90°design EFS - EXPERT-TÜNKERS Conveying System 9

Open the catalog to page 9

Application example 4 • • Accumulating conveyor for side panel Overhead operation EFS - EXPERT-TÜNKERS Conveying System 10

Open the catalog to page 10

Application example 5 Square operation Pallet with 4-fold support Stop station freely selectable Profile turned by 90 EFS - EXPERT-TÜNKERS Conveying System 11

Open the catalog to page 11

Application example 6 – Accumulating conveyor adjustable in width Dual-strand accumulating conveyor. The distance between the strands can be steplessly adjusted via a separate drive. Width steplessly adjustable Width steplessly adjustable EFS - EXPERT-TÜNKERS Conveying System 12

Open the catalog to page 12

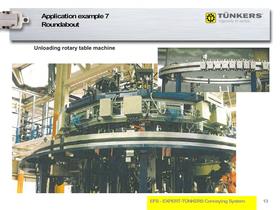

Application example 7 Roundabout Unloading rotary table machine EFS - EXPERT-TÜNKERS Conveying System 13

Open the catalog to page 13All TÜNKERS catalogs and technical brochures

-

Tünkers Multiflex Console

1 Pages

-

CLAMPING

3 Pages

-

Positioning

3 Pages

-

GRIPPING

3 Pages

-

FORMING

3 Pages

-

DOSING

2 Pages

-

WELDING

3 Pages

-

CONVEYING

3 Pages

-

TURNING

3 Pages

-

TRANSPORTING

3 Pages

-

Hydraulic Cylinder HYZ...

1 Pages

-

Lift Unit MZVD 40

1 Pages

-

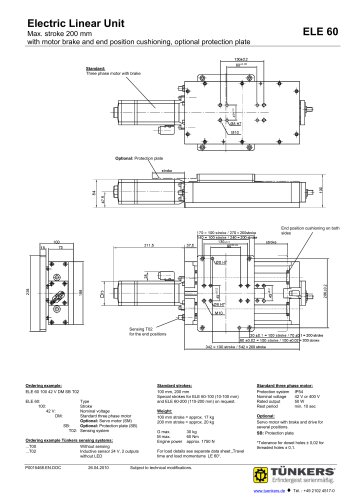

Electric Linear Unit ELE 60

1 Pages

-

TÜNKERS Imagepresentation

132 Pages

-

Hole and punching units

44 Pages

-

Manual clamps - Standard range

10 Pages