Website:

GEA Tuchenhagen

Website:

GEA Tuchenhagen

Group: GEA

Catalog excerpts

GEA Tuchenhagen Hygienic Centrifugal Pumps Business Line Hygienic Pump Technology Catalog 2014 engineering for a better world

Open the catalog to page 1

Publication date: 1/1/2014 The publication of specifications, technical data and information in written or electronic form does not release the user from the responsibility of checking for themselves all products delivered by us for suitability for the application(s) intended. These may be subject to change without prior notification. Errors and printing errors excepted - we assume no liability for the correctness of specifications given. The general sales terms and conditions for GEA Tuchenhagen GmbH. All rights reserved - copyright on all contents: GEA Tuchenhagen GmbH Am Industriepark...

Open the catalog to page 2

Table of Contents Pages Spare parts for TP and TPS series 120

Open the catalog to page 3

Our Business Unit GEA Flow Components Our main focus is on the growth and further strengthening of our market position as an internationally recognized technology leader in components for the food, pharmaceutical and biotechnology industries – mainly in the business areas of valves, pumps and cleaning technology. The GEA Group Every second litre of beer brewed in the world may well have flown through a component supplied by GEA Group. About every fourth litre of milk is extracted or further processed with equipment produced by GEA Group. One third of the worldwide instant coffee is produced...

Open the catalog to page 5

Business Line Hygienic Pumps Economically efficient Our Mission GEA Tuchenhagen products meet the growing demand for environmentally compatible components. Our basis for this is a future-oriented corporate and product concept committed to economic efficiency, sustainability and service-orientation. The current generation of GEA Tuchenhagen®-VARIFLOW pumps provide users with considerable cost savings. Sensibly rated high-efficiency motors in every dimension needed are available to cover the typical requirements of the markets. They enable that energy consumption is kept as low as possible,...

Open the catalog to page 6

Business Line Hygienic Pumps Lower consumption of energy, water and chemicals means less load on environment and climate. For GEA Tuchenhagen users, the future success of their business, and the continuing acceptance of their production site this aspect will become more and more important. Plant designers and engineering companies appreciate the benefits offered by GEA Tuchenhagen: they cannot only profit from a range of highly efficient products but also use the individually tailored engineering support available from GEA Tuchenhagen. On many markets, ecological criteria and the quality...

Open the catalog to page 7

GEA Tuchenhagen®-VARIFLOW Centrifugal Pumps The GEA Tuchenhagen®-VARIFLOW Centifugal Pump TP is designed for pumping demanding media up to a viscosity of 1,000 mPas. Low flow velocities and gentle discharge of media through the spiral housing ensure extremely gentle product handling and high efficiency. 10 pump sizes with a capacity range of up to 210 m3/h and pump heads of up to 90 m w.c. are available, finely tuned to the task at hand. Applications • Breweries Beer, wort, yeast, water, CIP solutions • Dairies Milk, cream, yoghurt, whey, brine, CIP solutions • Food Oils, sauces, stock,...

Open the catalog to page 8

GEA Tuchenhagen®-VARIFLOW Centrifugal Pumps Sealing according to the VARIVENT® principle The special groove enables the seal is kept reliably in place at all times. The shape of the groove is based on FEM analyses. The metallic stop allows a defined compression of the seal, ensuring gap-free sealing against the product chamber without dead corners. O-ring sealing between pump housing and cover FEM showing the seal ring in operating mode Centrifugal Pump TP Centrifugal Pump TPS 2 3 Rotor housing cover Circulation pipe Front rotor Clamp connection Rotor housing Centrifugal Pump TP/TPS 7...

Open the catalog to page 9

GEA Tuchenhagen®-VARIFLOW Centrifugal Pumps, Series TP and TPS Program overview

Open the catalog to page 10

GEA Tuchenhagen®-VARIFLOW Centrifugal Pumps, Series TP and TPS

Open the catalog to page 11

GEA Tuchenhagen Performance characteristics 50 Hz, GEA Tuchenhagen®-VARIFLOW, Series TP USGPM IGPM

Open the catalog to page 12

GEA Tuchenhagen Performance characteristics 60 Hz, GEA Tuchenhagen®-VARIFLOW, Series TP USGPM IGPM USGPM IGPM

Open the catalog to page 13

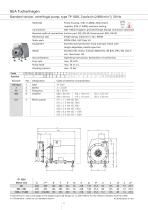

GEA Tuchenhagen Standard version, centrifugal pump type TP, 2-poles (n=2,900 min-1), 50 Hz Standard version Pump housing, 316L (1.4404), deep-drawn impeller, 316L (1.4409), precision casting DIN 11853-2 hygienic grooved flange (flange connection optional) Nominal width of connections Depending on pump size Mechanical seal Single-acting, material: C / SIC / EPDM Static seals Standard equipment Stainless steel protection hood and base frame with height-adjustable calotte-type feet Standard IEC motor, 3-phase 400V/±5%, IM B35, IP55, ISO class F, incl. thermistor, IE3 Operating instructions,...

Open the catalog to page 14

GEA Tuchenhagen Example of a standard selection Standard version, for other versions see options Type Speed Frequency Impeller Code of selection characteristics TP01020 2 = 2 pole 50 = 50 Hz 080 = 80 mm 090 = 90 mm Motor power 011 = 1.1 kW 015 = 1.5 kW 022 = 2.2 kW 030 = 3.0 kW 040 = 4.0 kW 055 = 5.5 kW Selected values determined by the pump selected Selection using the characteristic curves Performence curves, centrifugal pump, TP 1020 (2-pole / 50 Hz) H Impeller selection in accordance with capacity and pump head Impeller diameter Required NPSH-value Motor output selection in accordance...

Open the catalog to page 15

GEA Tuchenhagen Standard version, centrifugal pump, type TP 1020, 2-pole (n=2,900 min-1), 50 Hz Materials Pump housing, 316L (1.4404), deep-drawn impeller, 316L (1.4409), precision casting DIN 11853-2 hygienic grooved flange (flange connection optional) Nominal width of connections Suction port (SS), DN 50; Pressure port (DS), DN 40 Mechanical seal Single-acting, material C / SIC / EPDM Static seals Stainless steel protection hood and base frame with height-adjustable calotte-type feet Standard IEC motor, 3-phase 400V/±5%, IM B35, IP55, ISO class F, incl. thermistor, IE3 Documentation Flow...

Open the catalog to page 16

GEA Tuchenhagen Performance curves, centrifugal pump, type TP 1020, 2-pole (n=2,900 min-1), 50 Hz Required NPSH-value Required motor power Q [m3/h] The flow charts are based on a pumping medium of: densitiy 1 kg/dm3, viscosity 1 mm2/s, temperature 15°C, tolerance ±7% 17 Impeller diameter

Open the catalog to page 17All GEA Tuchenhagen catalogs and technical brochures

-

VESTA® Sterile Valves

8 Pages

-

Cleaning Technology

71 Pages

-

Catalog T-smart Butterfly Valves

94 Pages

-

VARIVENT®

32 Pages

-

Feedback Systems

36 Pages

-

STERICOM®

12 Pages

-

ECOVENT®

6 Pages

-

VARIVENT®

28 Pages

-

Catalog 2013

74 Pages

-

General Information

15 Pages

Archived catalogs

-

VARIPURE Rotating Cleaner

12 Pages

-

24/7 PMO Valve™

8 Pages

-

VESTA® Multiport

16 Pages

-

Zawory VARIVENT®

16 Pages