Website:

TTGroup

Website:

TTGroup

Group: TTGroup

Catalog excerpts

Vertical Machining Center •#** Tongtai Tongtai Machine & Tool Co., Ltd. Headquarters MEMBER OF China Operation Center No.3, Luke 3rd Rd., Luzhu Dist., Kaohsiung City 82151, Taiwan TEL : 886-7-9761588 www.tongtai.com.tw Taoyuan Branch Taichung Branch Japan Branch Europe Branch Malaysia Branch Vietnam Branch Thailand Branch Indonesia Office Members of TTGroup Shuzhou Tong-yu Machine & Tool Co., Ltd. No.555 Huahong Rd., Economic Development Zone of Wujiang, Suzhou City, Jiangsu Province, China TEL : 86-512-63430168 FAX : 86-512-63431622 E-mail :sales@tong-yu.com.cn www.tongtai.com.tw/cn Wuhan Branch Chongqing Branch Guandong Branch Tianjin Branch Shanghai Office Shenyang Office Asia Pacific Elite Corp. TEL : 886-4-23589313 FAX : 886-4-23588913 ANGER Machining GmbH TEL : 43-7229-71041-0 FAX : 43-7229-71041-199 www.anger-machining.com

Open the catalog to page 1

01 TMV-850Qll/1050Qll Vertical Machining Center TMV-850Qll/1050Qll Vertical Machining Center 02 TMV-850Qll/1050Qll • TMV-850Qll and TMV-1050Qll are the upgraded versions that allow the rapid traverse of up to 48 m/min. The rapid automatic tool changer shortens the T to T time less than 2 seconds. These features will provide the best investment return to the customers. • Excellent C type mechanical structure design provides high machine rigidity. It also assures excellent positioning accuracy during high speed and precision machining. • The integrated ergonomic working table design and...

Open the catalog to page 2

TMV-850Qll/1050Qll Vertical Machining Center TMV-850Qll/1050Qll Vertical Machining Center Main structure Preloaded Ballscrews X/Y/Z axis specification Servo motor We make pre-tensions on ball screws to maintain the positioning precision under the influence of thermal expansion effect on ball screws and meanwhile to decrease the bearing loads on ball screws. Rapid traverse X/Y/Z axis 48/48/48 m/min Chips removal design Chip-proof telescopic cover Dual chip augers are standard and the flushing system is optional for increasing the ability of chip disposal and decreasing the cleansing time....

Open the catalog to page 3

TMV-850Qll/1050Qll Vertical Machining Center TMV-850Qll/1050Qll Vertical Machining Center Main structure Automatic Tool Changer In TMV-850Qll and TMV-1050Qll series, the standard capacity of the tool magazine is 24 pieces. It uses a rapid tool changer to shorten idle time and achieves the goal of high efficiency machining. Tool capacity 24 (30) pcs Tool changing time Direct-drive motor •Spindle is connected with motor by coupling •Spindle cooler is available •Coolant through spindle is available (αT8 motor only) Belt type spindle Standard Belt-type : 8,000 rpm Optional Belt-type : 10,000...

Open the catalog to page 4

07 TMV-850Qll/1050Qll Vertical Machining Center TMV-850Qll/1050Qll Vertical Machining Center 08 Main structure Examples of application Table size (LxW) 850QII 1050QII Working area (LxWxH) Machining efficiency improvement test The below graphs show the comparison between TMV-850A and TMV-850QII. In the practical applications, the TMV-850QII saves 10% more machining time than the TMV-850A. Furthermore, to compare the different machining modes, the TMV-850Q has better performance than TMV-850A , especially in tapping. Maximum table load 800 kg Table height from floor 900 mm Cycle time...

Open the catalog to page 5

TMV-850Qll/1050Qll Vertical Machining Center TMV-850Qll/1050Qll Vertical Machining Center Peripheral accessories Tongtai- Technical Application Center Precision testing The purpose of T-TAC is to take care of customer’s machining solution actively. Based on the outstanding technical applications, Tongtai is able and willing to provide advanced machining technologies, machining solutions as well as trial tests to its customers and ensures them of excellent experiences in machine operation, maintenance convenience and machine availabity. For assuring assembly precision, Tongtai not only sets...

Open the catalog to page 6

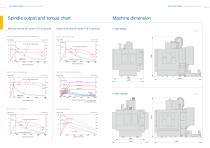

TMV-850Qll/1050Qll Vertical Machining Center TMV-850Qll/1050Qll Vertical Machining Center Spindle output and torque chart Machine dimension Belt type spindle (All series CTS is optional) Continued operation zone 4000 Direct-drive type (All series CTS is optional) Low speed winding High speed winding Continued operation zone 4000 Spindle spee

Open the catalog to page 7

13 TMV-850Qll/1050Qll Vertical Machining Center TMV-850Qll/1050Qll Vertical Ma chining Center 14 Optional accessories Specifications Coolant through spindle Spindle chiller Tool breakage detector Chip conveyor Tri-color warming light © Specifications may be changed without prior notifications

Open the catalog to page 8All TTGroup catalogs and technical brochures

-

CNC LATHE / MILLING THL-620

8 Pages

-

CNC LATHE

8 Pages

-

CNC LATHE / MILLING

8 Pages

-

CNC LATHE / COMPACT/Q5

2 Pages

-

CNC LATHE / 3-AXIS/MT Series

10 Pages

-

CNC LATHE / MILLING/HS-22[M]

8 Pages

-

CNC LATHE / COMPACT/A-1500

6 Pages

![CNC LATHE / MILLING/HS-22[M]](https://img.directindustry.com/pdf/repository_di/27273/cnc-lathe-milling-hs-22-m-814979_1mg.jpg)