Catalog excerpts

Timken® Lubricants Boost Efficiency

Open the catalog to page 1

Choose Timken® Lubricants for Optimal Performance The right lubrication and lubricant delivery systems can help extend bearing life, protect your equipment, reduce costs and keep your operations running efficiently. Timken expertise in tribology and bearings gives you a reliable line of lubricants developed for specific applications and environments. High-temperature, anti-wear and waterresistant additives help provide superior protection in particularly challenging environments where dirt, corrosion and other contaminants are common. When you choose Timken as your lubrication resource, you...

Open the catalog to page 2

Select Your Grease Carefully for Reliable Performance Identifying the optimal grease requires a good understanding of each specific application, particularly operating load, speed, temperature and ambient conditions. There is no universal anti-friction bearing grease.Each grease has limiting properties and characteristics. Bearing grease is composed of a base-oil, a thickening agent and additives.Specific base-oils are designed to handle certain applications and environments: Demanding applications Recommended base-oil High viscosity with extreme pressure (EP) additive/solid lubricants...

Open the catalog to page 3

Timken® Construction and Off-Highway Grease • Part #GR219 • NLGI No. 2 calcium sulfonate grease with 5 percent moly • rovides resistance to extreme pressures caused by shock loading P • Timken OK Load – 65 lbs. • Protects against rust and corrosion • Offers excellent high-temperature properties • perating temperatures of -40° C to 204° C (-40° F to 400° F) O • pplications: High-load, low-speed applications such as mining, A draglines, construction equipment, agriculture machinery, bulldozers, scrapers, earthmovers, cranes, backhoes, shovels, rollers, tractors, combines and cotton pickers •...

Open the catalog to page 4

Trust Timken to keep you rolling forward Around the world, customers use Timken lubricants for rail bearings, rolling mills, power generation equipment, construction and transportation vehicles, and multiple demanding industrial applications. With more than a century of leadership in developing friction management solutions, Timken is a trusted source for a broad range of bearings – and mechanical power transmission products that help keep your operations performing efficiently and reliably, even in the toughest environments.We use our knowledge to make the world’s industries work better....

Open the catalog to page 5

Four Ball Wear, ASTM D2266, 40 kg, 167° F, scar mm Timken OK Load ASTM D2509, lbs. Operating Temperature Limit, ° F 300 How do Timken lubricants measure up? The American Society for the Testing of Materials (ASTM) established standards for the testing of lubricating greases. Wheel Bearing Life, ASTM D3336, hrs@350° F 250 500 >750 This table displays the typical range of test results reported by the lubricant companies for each test and ranks750 them Water Washout, ASTM D1264, 175° F, % loss 10 5 2 2 as good, better or best, compared with the corresponding Timken grease characteristics....

Open the catalog to page 6All TIMKEN catalogs and technical brochures

-

National® Industrial Seals

716 Pages

-

TIMKEN® ECOTURN® SEAL

2 Pages

-

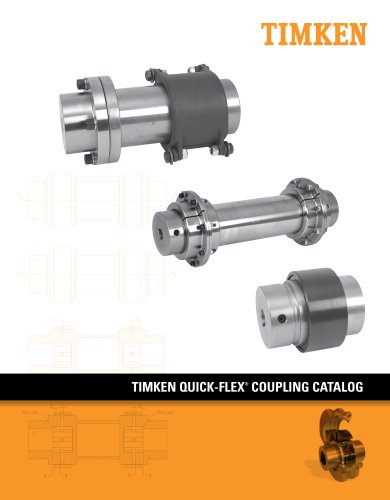

Quick-Flex Couplings

68 Pages

-

Matched Bearing Assemblies

16 Pages

-

Cylindrical Roller Bearings

108 Pages

-

AP Bearings

84 Pages

-

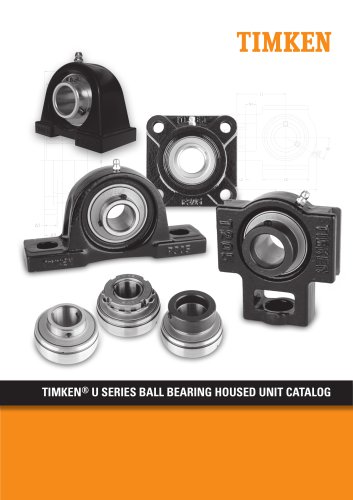

UC Series Ball Housed Units

24 Pages

-

Type E Housed Units

40 Pages

-

Ball Housed Units

180 Pages

-

SNT Plummer Blocks

120 Pages

-

SAF Housed Units

126 Pages

-

Thrust Bearings

138 Pages

-

Quick-Flex Coupling Catalog

68 Pages

-

Bearing interchange guide

163 Pages

-

UC-SERIES

24 Pages

-

Quick-Flex Coupling

64 Pages

-

Timken Drives Roller Chain Catalog

112 Pages

-

Commercial Vehicle Catalog

417 Pages

-

Industrial Maintenance Manual

157 Pages

-

Timken SAF Housed Unit Catalog

126 Pages

-

Timken Ball Housed Unit Catalog

180 Pages

-

Timken® SNT Plummer Block Catalog

120 Pages

-

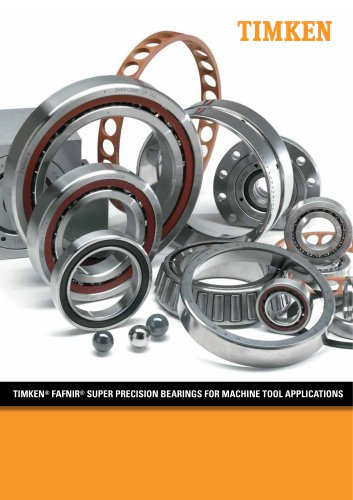

BALL BEARINGS

214 Pages

Archived catalogs

-

COMPETENCYBASED TRAINING

5 Pages

-

Spherical Roller Bearings

236 Pages

-

Timken Engineering Manual

210 Pages

-

Timken Ball Bearings Catalog

217 Pages

-

Timken Industrial Seals

40 Pages

-

Ball Bearings

6 Pages

-

IsoClass Bearings

8 Pages

-

Maintenance Tools

16 Pages

-

Industrial Products

56 Pages

-

Precision Rotary Assemblies

2 Pages

-

Ceramic Bearings

2 Pages