Website:

TEBIS

Website:

TEBIS

Catalog excerpts

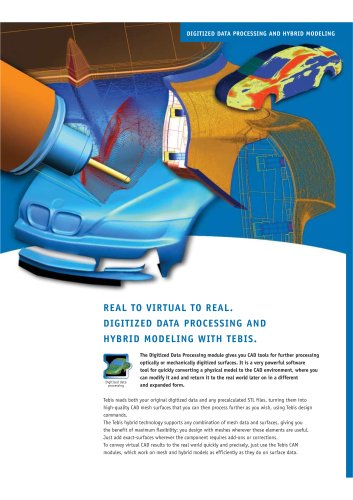

DIGITIZED DATA PROCESSING AND HYBRID MODELING REAL TO VIRTUAL TO REAL. DIGITIZED DATA PROCESSING AND HYBRID MODELING WITH TEBIS. The Digitized Data Processing module gives you CAD tools for further processing optically or mechanically digitized surfaces. It is a very powerful software tool for quickly converting a physical model to the CAD environment, where you can modify it and and return it to the real world later on in a different and expanded form. Tebis reads both your original digitized data and any precalculated STL files, turning them into high-quality CAD mesh surfaces that you can then process further as you wish, using Tebis design commands. The Tebis hybrid technology supports any combination of mesh data and surfaces, giving you the benefit of maximum flexibility: you design with meshes wherever these elements are useful. Just add exact-surfaces wherever the component requires add-ons or corrections. To convey virtual CAD results to the real world quickly and precisely, just use the Tebis CAM modules, which work on mesh and hybrid models as efficiently as they do on surface data. Digitized data processing

Open the catalog to page 1

TEBIS CAD - DIGITIZED DATA PROCESSING Precision is the basis for high-quality processes. A tiny error or inaccuracy in one step tends to escalate through each successive level, so Tebis implements a whole raft of functions for optimizing scan data. The return on time invested at this stage is enormous, because this is the basis for the next, crucial step in CAD processing – conversion into triangle-mesh constructs of the part. The computing and filter routines in the Tebis Mesh Triangulator module are so sensitive and precise that the digitized surface is modeled perfectly in the CAD...

Open the catalog to page 2

Tebis has a complete toolset for modifying meshes. Imported or system-generated meshes are cut open along reference curves to harmonize with predefined installation requirements. Original meshes (yellow) can be manipulated to obtain, for example, a tangential with a precision edge to fit snugly against a defined surface or a curve (blue). Follow-up processes sometimes call for more precision than meshes can supply, so polynomial surfaces can be constructed on the basis of automatically generated curves of intersection. This is the time-saving way of modeling complex mold blocks as...

Open the catalog to page 3

Tebis Technische Informationssysteme AG, Einsteinstr. 39, D–82152 Mart insried/Munich, Tel. +49 / 89 / 81 803-0, info@tebis.com, www.tebis.com Over 1,000 companies throughout the world use Tebis workstations. Users in a wide variety of industries, from independent engineers to globally operating car manufacturers with several hundred licenses, depend on the powerful capabilities of their Tebis systems. The range of software applications and related requirements are equally diverse. Tebis meets these strict and frequently special requirements by providing a broad spectrum of universally...

Open the catalog to page 4All TEBIS catalogs and technical brochures

-

Tebis Viewer pages 8

8 Pages

-

Multiple setup

2 Pages

-

Tebis Viewer pages 2

2 Pages

-

5 Axis Trimming

4 Pages

-

DNC

4 Pages

-

Frontends01

4 Pages

-

Simulator

8 Pages

-

Lathe_A4_2011

6 Pages

-

Tebis_ProductRange

45 Pages

-

wire-edm

8 Pages

-

laser-cutting

4 Pages

-

TEBIS-FARO INTEGRATION

4 Pages

-

tebis Products

45 Pages

-

FEATURE DESIGN

8 Pages

-

ELECTRODE DESIGN

4 Pages

-

THE TEBIS BREP PRODUCT GROUP

12 Pages