Website:

Sumitomo Hardmetal Division

Website:

Sumitomo Hardmetal Division

Group: Sumitomo

Catalog excerpts

TOOLING NEWS A Revolution in Deep Drilling Super Multi-Drill XHT/PHT type (Deep hole) (Pilot hole) le aster th ing cyc F ut peck xD - witho p to 30 oval pth u hip rem De ient c for effic design ue flute Uniq

Open the catalog to page 1

• Drills faster than conventional high speed drills and gun drills • Unique flute design efficiently removes chips • Solid carbide construction provides excellent finished hole geometry • Low cutting forces - suitable for low powered machine spindles • Eco-friendly - uses MQL (minimum quantity lubrication) systems Chip form examples using alternative coolant methods • MQL chips well across a wider range of cutting • MQL works well even when drilling soft steels chip evacuation Coolant supply Internal coolant (Emulsion 3MPa) | Internal MQL (Vegetable oil 0,6MPa) I Oil hole drilling on...

Open the catalog to page 2

MDW…XHT Type for Deep Hole Dimensions øD (mm) Stock Dimensions Stock Dimensions Stock Dimensions Stock Dimensions Stock Dimensions 87 58 107 78 127 ● ● ● 4,0 4,0 MDW 040 XHT S HAK 95 63 118 86 140 ● ● ● 4,5 MDW 045 XHT S HAK 5,0 98 68 123 93 148 ● ● 5,0 MDW 050 XHT S HAK5 (*) ● 106 68 131 93 156 ● ● ● 5,0 MDW 050 XHT S HAK 113 73 141 101 168 ● ● ● 5,5 MDW 055 XHT S HAK 6,0 118 78 148 108 178 ● ● ● 6,0 MDW 060 XHT S HAK 125 87 158 120 190 ● ● ● 6,5 MDW 065 XHT S HAK 131 92 166 127 201 ● ● ● 7,0 MDW 070 XHT S HAK 8,0 136 97 174 135 211 ❍ ❍ ❍ 7,5 MDW 075 XHT S HAK 141 102 181 142 221 ● ● ● 8,0...

Open the catalog to page 3

Tooling Strategy 1. A B: Preperation of pilot hole with MDW …PHT type vc= 50-80m/min, f= 0,15-0,25mm/rev, doc:1-2xD 2. A C: Entering into pilot hole with long Multi-Drill (MDW ….XHT type) N= 500 rpm, vf =2000mm/min At C the drill should stay (about. 3 sec.) and increase speed to set recommended cutting conditions. 3. C D: Deep hole drilling After reaching required number of revolution operation can be started taking into consideration mentioned recommendation for the feed rates. At cross holes and irregular or angled surfaces feed should be reduced. 4. D E: After hole drilling Decrease...

Open the catalog to page 4

Application Examples Work piece: Crank shaft (C45E, 1.1191) Machine Machine: Horizontal M/C Coolant: MQL (Synthesized ester) Air pressure 0,9MPa Supplying rate 20cc/h Process and cutting condition 1) Pilot hole (ø5,75 x 12mm, Top angle of drill: 150°) Vc=80m/min f=0,2mm/rev. 2) Deep hole (ø5,70 x 83mm x 4 holes, XHT type) Vc=100m/min f=0,15mm/rev. F=873mm/min Cutting edge after 66,4m drilling Work piece: Cutting tool body (42CrMo4, 1.7225: 35~38HRC) Machine Machine: Vertical M/C (BT40) Coolant: Internal cooling (Emulsion) Pump pressure 3,0MPa Process and cutting condition 1) Pilot hole...

Open the catalog to page 5

Service in Europe ● Regrinding and recoating service of Multi-drill XHT/ PHT type available in Europe. ● Drills with another geometry (diameter or length) can be produced in Europe. ● Sumitomo can propose suitable drill geometry for the material other than steel. ( Germany ) SUMITOMO ELECTRIC Hartmetall GmbH Siemensring 84, D - 47877 Willich Tel. ( 02154 ) 49 92-0, FAX ( 02154 ) 4 10 7 2 e-Mail: Info@SumitomoTool.com Internet: www.SumitomoTool.com Sumitomo Electric Hartmetallfabrik GmbH in D-73466 Lauchheim Production works in Germany ( UK and Ireland ) SUMITOMO ELECTRIC Hardmetal Ltd....

Open the catalog to page 6All Sumitomo Hardmetal Division catalogs and technical brochures

-

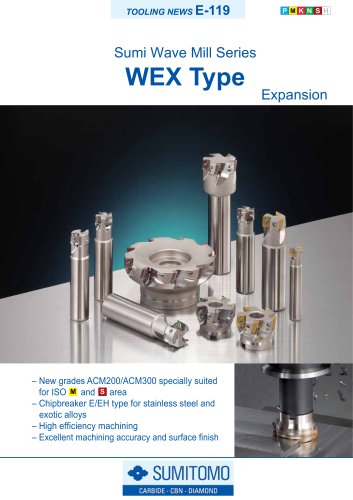

E-119 WEX Sumi Wave Mill Series

12 Pages

-

SumiTurn T-REX

4 Pages

-

WaveMill WEX Series

6 Pages

-

Technical Guidance

52 Pages