Website:

Sumitomo Hardmetal Division

Website:

Sumitomo Hardmetal Division

Group: Sumitomo

Catalog excerpts

TOOLING NEWS Coated CBN Inserts for Turning Hardened Steels New cutting edge geometries to optimise performance One-use multi cornered inserts to optimise tooling cost Wide range of grades to optimise machining cost

Open the catalog to page 1

SUMIBORON series BNC200 is the first recommendation to machine hardened steels - Building on its global success machining hardened steels with Sumiboron inserts the addition of heat and wear resistant coatings to a variety of tough new CBN substrates has resulted in a new generation of high performance inserts. With economy in mind the new inserts are multi cornered. Choose the coated insert suitable for your application and take your hard part machining operations to the new industry standard. Coated CBN Grades and Application Grade High precision continuous cutting High precision grade...

Open the catalog to page 2

CBN Insert Guide Insert types and cutting edge geometries Multi Cornered One-Use Type Inserts G One-use type inserts improve machining efficiency by using each cutting edge to its full potential following the numbering system on each cutting edge then throwing the insert away. G Multi cornered inserts have a single piece of Sumiboron mounted on every useable corner. Single sided inserts use the top corners whilst double sided inserts use both top and bottom corners. Diamond shaped inserts have 4 corners and triangular inserts have 6 corners. G A variety of Sumiboron coated grades readily...

Open the catalog to page 3

Coated SUMIBORON Coated Sumiboron premium grade for high speed machining of hardened steels General Our copper coloured Sumiboron grade BNC 100 resists premature plastic deformation of the cutting edge by withstanding the high temperatures that occur when machining hardened steels. This new grade features a heat resistant CBN substrate and a special TiCN base ceramic coating to enhance surface finish across a broad range of finishing applications at elevated cutting speeds. Ideal for higher speed machining and suitable for continuous or light interrupted cuts BNC100 delivers reliable...

Open the catalog to page 4

Coated SUMIBORON High precision machining with surface finishes down to 1,6 Rz possible thanks to smooth coating! - Use the copper coloured Sumiboron grade BNC160 to improve surface integrity as well as machining accuracy. The TiCN-base smooth surface ceramic coating and the newly developed Sumiboron substrate enhances edge strength and wear resistance making high precision machining with surface finishes as low as 1,6Rz readily achievable. This new grade is ideal for turning components that previously relied on precision grinding machines for final machining. G Excellent surface roughness!...

Open the catalog to page 5

Coated SUMIBORON Excellent wear and fracture resistance! Predictable tool life on a wide range of applications! General Our silver coloured Sumiboron insert grade BNC200 offers safe reliable cutting and predictable tool life. The newly developed cutting material with enhanced edge strength is coated with TiAlN-base ceramic for excellent wear resistance and realises extended tool life even when interrupted cutting. This grade is especially suitable for medium speed machining of carburised surfaces. G Predictable tool life! Extended tool life is realised even when high speed cutting thanks to...

Open the catalog to page 6

Coated SUMIBORON BNC300 Coated grade BNC300 for heavy interrupted hard turning General Use our gold coloured Sumiboron grade BNC300 to machine hardened steel parts which have heavy interruptions. The tough new CBN substrate in combination with the tough wear resistant coating responds well to applications where cuts over surfaces which are heavily interrupted by grooves, cross holes, etc have to be undertaken. G Stable tool life! Tough CBN substrate and wear resistant coating provides stable tool life even when cuts are heavily interrupted. G Excellent machining accuracy! The wear resistant...

Open the catalog to page 7

One-Use Inserts CNGA / CNGG GGGGGG G-Class SumiBoron (CBN, One-Use Multi-Corner Type) Shape Standard Normal cut geometry (Wiper Type) HS - Type Tough cut geometry with 2 CBN cutting edges with 2 CBN cutting edges SV - Type with chipbreaker LS - Type Light cut geometry HS - Type Tough cut geometry with 4 CBN cutting edges with 2 CBN cutting edges with 2 CBN cutting edges DNGG 150604 N-SV NC4 DNGG 150608 N-SV NC4 DNGG 150612 N-SV NC4 with 2 CBN cutting edges Break Master - SV SV - Type with chipbreaker with 4 CBN cutting edges G-Class SumiBoron (CBN, One-Use Multi-Corner Type) Standard Normal...

Open the catalog to page 8

Coated SUMIBORON One-Use Inserts SNGA GGGGGG G-Class SumiBoron (CBN, One-Use Multi-Corner Type) Shape HS - Type Tough cut geometry with 2 CBN cutting edges HS - Type Tough cut geometry TNGG 160404 N-SV NC6 TNGG 160408 N-SV NC6 TNGG 160412 N-SV NC6 with 3 CBN cutting edges with 6 CBN cutting edges with 3 CBN cutting edges SV - Type with chipbreaker G-Class SumiBoron (CBN, One-Use Multi-Corner Type) LS - Type Light cut geometry with 4 CBN cutting edges TNGA / TNGG GGGGGG Standard Normal cut geometry Standard Normal cut geometry with 6 CBN cutting edges Packing unit and ordering example: 1 pce

Open the catalog to page 9

CCGW GGGGGG G-Class SumiBoron (CBN, One-Use Multi-Corner Type) Shape Standard Normal cut geometry with 2 CBN cutting edges One-Use Inserts (Wiper Type) LS - Type Light cut geometry HS - Type Tough cut geometry with 2 CBN cutting edges G-Class SumiBoron (CBN, One-Use Multi-Corner Type) Shape with 2 CBN cutting edges HS - Type Tough cut geometry G with 2 CBN cutting edges with 2 CBN cutting edges DCGW 070202 LS-NC2 DCGW 070202 LS-NC2 LS - Type Light cut geometry with 2 CBN cutting edges DCGW GGGGGG Standard Normal cut geometry Coated SUMIBORON Packing unit and ordering example: 1 pce

Open the catalog to page 10

Coated SUMIBORON One-Use Inserts TPGW GGGGGG VBGW GGGGGG with 2 CBN cutting edges with 2 CBN cutting edges with 2 CBN cutting edges G-Class SumiBoron (CBN, One-Use Type) Shape ZNEX 040102 NC ZNEX 040104 NC ZNEX 040108 NC ZNEX GGGGGG HS - Type Tough cut geometry LS - Type Light cut geometry Standard Normal cut geometry VBGW 110202 NC VBGW 110204 NC VBGW 110208 NC VBGW 160404 NC-2 VBGW 160408 NC-2 Standard Normal cut geometry G-Class SumiBoron (CBN, One-Use Type) Standard Normal cut geometry G-Class SumiBoron (CBN, One-Use Type) Shape Packing unit and ordering example: 1 pce

Open the catalog to page 11All Sumitomo Hardmetal Division catalogs and technical brochures

-

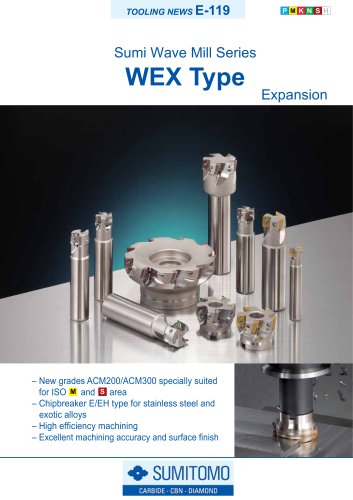

E-119 WEX Sumi Wave Mill Series

12 Pages

-

SumiTurn T-REX

4 Pages

-

XHT/PHT Multi-Drills

6 Pages

-

WaveMill WEX Series

6 Pages

-

Technical Guidance

52 Pages