Website:

SULLAIR

Website:

SULLAIR

Group: UTC

Catalog excerpts

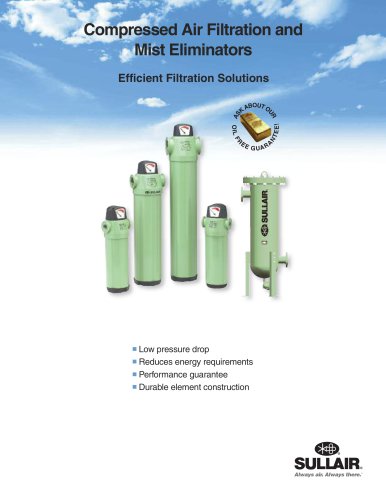

Engineered Molecular Filtration Ⅲ No Messy Element Changes Ⅲ Separates Emulsified Condensate Ⅲ Guarantee Less Than 10 ppm Carryover Ⅲ Maintenance Free

Open the catalog to page 1

Sullair Capabilities products are known around the world for their universally applicable design, outstanding craftsmanship and superior quality. Sullair Leadership Since 1965, Sullair has been recognized around the world as an innovator and a leader in rotary screw compression and vacuum technology. For more than 40 years, Sullair has designed and manufactured its own rotors and air end assemblies at the corporate headquarters in Michigan City, Indiana. The award-winning rotary screw design sets the industry standards and delivers the quality and reliability one expects from a leader....

Open the catalog to page 2

The Performance of Sullair’s SP Oil / Water Separators The Problem Compressed air systems generate liquid condensate that is a combination of water, oil and various other contaminants. Failure to remove these contaminants is bad for the environment and risks substantial regulatory penalties and costly remediation. For example: A 1000 cfm (1700 m3/hr) compressor with a refrigerated dryer can produce over 57,000 gallons (216 m3) of condensate per year. One gallon of oil can cover 4 acres of water surface. This oil: • Inhibits the operation of water treatment plants by choking bacteria used...

Open the catalog to page 3

Features and Benefits of Sullair’s SP Oil / Water Separator • Less than 10 ppm guarantee • Rugged HDPE construction • Easy installation • Place it and forget it • Maintenance free • No pumps, sensors, or pre-separation filter pads • No messy element changes • No power consumption • No fumes • No odors • Disposal as non-hazardous special waste • Environmentally considerate SP’s are proven to handle condensate containing these common compressor lubricants (including emulsified and silicone condensate solutions) (NOTE: ++ Silicone Pak required): •Polyglycols • Diester-based lubricants •...

Open the catalog to page 4

How the SP Oil / Water Separator Works 1. SP model Oil / Water Separators are simple, efficient, and maintenance free. 2. The condensate from the waste stream is piped directly into the SP inlet and flows through a specially engineered internal decompression chamber. 3. The condensate comes into contact with the media bed and the lubricant bonds to the media bed. 4. The cleansed water passes through the media and flows to the outlet. 5. Monitor Water discharged from SP Oil / Water Separators 6. When planned change period is reached or water turns cloudy the separator should be replaced....

Open the catalog to page 5

Model Selection and Size Table Any size SP Oil / Water Separators can be used with all compressor sizes regardless of lubricant or humidity; the amount of lubricant in condensate determines the lifespan of each unit. This hour chart is based on 3.5 ppm carryover performance. Life expectancy of the SP Oil / Water Separators depends on the amount of lubricant carryover from the compressor(s). Contaminant absorption capacity is approximately 50% of media bed volume. Discharge scfm APPLICATION NOTES: 1. Application Chart calculations are operating hours and typical operating condensate flows....

Open the catalog to page 6

Air Quality Standards ISO 8573.1 Classes Particle (micron) size of some common substances. Eye Sight Threshold (40 micron) Fumes Tobacco Smoke Smog Oil Aerosols Solid Particle Maximum number of particles per m3 General Purpose Protection Air quality to ISO 8573.1 Quality Class 1.-.5 Oil-Free Air Air quality to ISO 8573.1 Quality Class 1.4.3 Critical Applications Air quality to ISO 8573.1 Quality Class 1.4.1 Low Dew Point Quality Class 1.2.1 Pressure Dew Point -40°F (-40°C) Extremely Low Dew Point Air quality to ISO 8573.1 Quality Class 1.1.1 Pressure Dew Point -100°F (-73°C) FXF

Open the catalog to page 7

Sullair’s Compressed Air Products www.sullair.com Fundamental to Sullair’s leadership is a dedication to reduce not only the amount of natural resources consumed to create energy, but to minimize environmental impact, in both the manufacture and use of all our products. We are constantly exploring new ideas and seeking new technologies to meet the ever-increasing need for high quality, energy-efficient compressed air products and environmental sustainability. © Copyright 2013 Sullair. All rights reserved. The color green is a registered trademark of Sullair. Specifications subject to change...

Open the catalog to page 8All SULLAIR catalogs and technical brochures

-

AWF® All Weather Fluid

2 Pages

-

The SULLAIR 900H

2 Pages

-

Sullair SRF 1/4000®

2 Pages

-

Pristine FG™

2 Pages

-

SULLAIR Two-stage

12 Pages

-

The SULLAIR 425H

2 Pages

-

The Sullair 1600

2 Pages

-

The SULLAIR 375HH

2 Pages

-

900XHH/1150XH

2 Pages

-

ES-6 S-energy

8 Pages

-

S-energy

8 Pages

-

SULLAIR Air Treatment

19 Pages

-

LS Series

20 Pages

-

The Sullair 1300H

2 Pages

-

ShopTek

4 Pages

-

Sullair 260 Series

4 Pages

-

The Sullair 375H

2 Pages

-

MBT-6 Backfill Tamper

16 Pages

-

Air Audits

2 Pages

-

OFS series

8 Pages

-

SULLAIR FD1550

4 Pages

-

SRL series

8 Pages

-

DSP series

8 Pages

-

Sullair SRF 1/4000

2 Pages

-

SULLAIR Single-stage

8 Pages

-

Centrifugal compressors

12 Pages

-

Flowlogic

8 Pages

-

S-energy

16 Pages

-

S energy

16 Pages

-

900XHH-1150XHDL

2 Pages

-

Heat Recovery—S-energy® EES

8 Pages

-

Sullair Vacuum System

8 Pages

-

1150XHH/1350XHDL

2 Pages

-

750XHH/900XHDL

2 Pages

-

TSR-20

2 Pages

-

TSR-32

2 Pages

-

DR-13

2 Pages

-

Desiccant Regenerative Dryers

12 Pages

-

DR13

2 Pages

-

DE18

2 Pages

-

TSR20

2 Pages

-

RDHL

2 Pages

-

SSL10

16 Pages

Archived catalogs

-

shoptek

8 Pages

-

SULLAIR Air Treatment

30 Pages

-

ShopTek

8 Pages