Website:

SULLAIR

Website:

SULLAIR

Group: UTC

Catalog excerpts

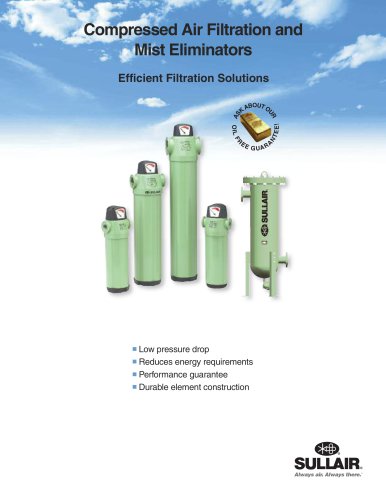

Desiccant Regenerative Dryers ■ Desiccant Externally Heated ■ Desiccant Blower Purge Always air. Always there.'

Open the catalog to page 1

Sullair Capabilities products are known around the world for their universally applicable design, outstanding craftsmanship and superior quality. Sullair Leadership Since 1965, Sullair has been recognized around the world as an innovator and a leader in rotary screw compression and vacuum technology. For more than 40 years, Sullair has designed and manufactured its own rotors and air end assemblies at the corporate headquarters in Michigan City, Indiana. The award-winning rotary screw design sets the industry standards and delivers the quality and reliability one expects from a leader....

Open the catalog to page 2

The Importance of Clean, Dry Compressed Air How much water is too much? Any amount of water is too much. Water jeopardizes everything you want your compressed air system to do. It ruins product and fouls processes. • Relative humidity is the amount of water vapor in air relative to what it could hold at a given temperature • Moisture in compressed air remains in a vapor state through the compression cycle, so it is not a problem until it leaves the compressor Liquid remaining after the aftercooler: 14.7 gallons (32%) • Air discharged from a compressor is approximately 150°F to 450°F • At...

Open the catalog to page 3

Features of the Sullair Desiccant Dryers DHL Series Standard Features (80-5,000 scfm) Pre- and after-filter pre-piped and mounted Field adjustable drying cycle time Pilot air filter Easy front access control panel -40°F pressure dew point Fully automatic self contained dryer Adjustable purge valves High quality valves Purge flow indicator ASME/CRN code welded pressure vessels UL/CUL electrical certified Separate drain and fill port Robust steel frame with floor stand Separate safety pressure relief valve for each tank • Stainless steel inlet/outlet diffusers DEX and DBP Series Standard...

Open the catalog to page 4

Principle of Operation for Sullair’s Desiccant Dryers Desiccant Heatless 6 Principle of Operation for Desiccant Heatless Dryers The dual tower design allows for continuous absorption of water from compressed air by using a hygroscopic high crush strength desiccant. Drying is accomplished by passing compressed air through the desiccant bed absorbing moisture while the other is being simultaneously regenerated with the expanded purge air. Left Tower Right Tower Regeneration of the desiccant is accomplished without the use of heat. The wet bed is dried by diverting a small amount of dry air...

Open the catalog to page 5

Advantages of Sullair’s Heated Desiccant Dryers Advanced PLC Controller Butterfly Valve A programmable PLC controller with back lit display is standard on all DHL series dryers. The controller is simple to use and comes standard with these great features: • PLC Read Out • Adjustable Cycle Time • Filter Change Alarm • Failure to Switch Contact • Dew Point Monitoring Contacts • Red Light Alarm Indicator These versatile valves provide precision control and bubble tight shut off. The digitally controlled actuators have easy PLC interface and feature fast response times. The tongue-and-groove...

Open the catalog to page 6

Sullair's Heatless Desiccant Modular Dryers Desiccant Modular Dryer (DMD) Standard Features • Completely automatic • Compact design • Adjustable wall mounted • Quick and easy connection • Long lasting high quality components Desiccant Modular Dryer (DMD) Options • Pre- and after-filter (shipped loose) • Mounted filters with three valve bypass • Visual Moisture Indicator • Energy efficient Demand Cycle Control with dew point monitor Desiccant Modular Dryer 2 Purge exhaust valve 4 Outlet check valve 5 Pressure relief valve 6 Purge adjustment valve 7 Stainless steel inlet defuser 8 Purge...

Open the catalog to page 7

Specifications: Desiccant Heatless Dryer Inlet–Outlet Connection Capacity Correction Factors (for all Sullair Desiccant Dryers) Correction factor for Inlet Air Pressure (F1) Inlet Pressure psig 50 60 bar 3.5 4.1 Factor Pressure: F1 0.56 0.65 Air flow capacity = Nominal capacity of the dryer x Factor F1 x Factor F2.

Open the catalog to page 8

Specifications: Desiccant Externally Heated Dryer Inlet–Outlet scfm Connection Air flow capacity = Nominal capacity of the dryer x Factor F1 x Factor F2.

Open the catalog to page 9

Sullair Air Quality Guarantee Two Levels of Air Quality Sullair recognizes that the requirements for air quality vary according to each compressed air application. For this reason, Sullair provides compressed air systems that achieve two distinct levels of air quality and a guarantee for each. Sullair Stationary Air Power System The Sullair Stationary Air Power System matches a Sullair compressor, a Sullair dryer and Sullair filters. Sullair assures that its System will meet specific performance levels throughout its operational life. We offer a one-year test/review period, backed by a...

Open the catalog to page 10

Air Quality Standards ISO 8573.1 Classes Particle (micron) size of some common substances. Eye Sight Threshold (40 micron) Fumes Tobacco Smoke Smog Oil Aerosols Solid Particle Maximum number of particles per m3 General Purpose Protection Air quality to ISO 8573.1 Quality Class 1.-.5 Oil-Free Air Air quality to ISO 8573.1 Quality Class 1.4.3 Critical Applications Air quality to ISO 8573.1 Quality Class 1.4.1 Low Dew Point Quality Class 1.2.1 Pressure Dew Point -40°F (-40°C) Extremely Low Dew Point Air quality to ISO 8573.1 Quality Class 1.1.1 Pressure Dew Point -100°F (-73°C) FXF

Open the catalog to page 11

Sullair’s Compressed Air Products www.sullair.com Fundamental to Sullair’s leadership is a dedication to reduce not only the amount of natural resources consumed to create energy, but to minimize environmental impact, in both the manufacture and use of all our products. We are constantly exploring new ideas and seeking new technologies to meet the ever-increasing need for high quality, energy-efficient compressed air products and environmental sustainability. © Copyright 2013 Sullair. All rights reserved. The color green is a registered trademark of Sullair. Specifications subject to change...

Open the catalog to page 12All SULLAIR catalogs and technical brochures

-

AWF® All Weather Fluid

2 Pages

-

The SULLAIR 900H

2 Pages

-

Sullair SRF 1/4000®

2 Pages

-

Pristine FG™

2 Pages

-

SULLAIR Two-stage

12 Pages

-

The SULLAIR 425H

2 Pages

-

The Sullair 1600

2 Pages

-

The SULLAIR 375HH

2 Pages

-

900XHH/1150XH

2 Pages

-

ES-6 S-energy

8 Pages

-

S-energy

8 Pages

-

SULLAIR Air Treatment

19 Pages

-

LS Series

20 Pages

-

The Sullair 1300H

2 Pages

-

ShopTek

4 Pages

-

Sullair 260 Series

4 Pages

-

The Sullair 375H

2 Pages

-

MBT-6 Backfill Tamper

16 Pages

-

Air Audits

2 Pages

-

OFS series

8 Pages

-

SULLAIR FD1550

4 Pages

-

SRL series

8 Pages

-

DSP series

8 Pages

-

Sullair SRF 1/4000

2 Pages

-

SULLAIR Single-stage

8 Pages

-

Centrifugal compressors

12 Pages

-

Flowlogic

8 Pages

-

S-energy

16 Pages

-

S energy

16 Pages

-

900XHH-1150XHDL

2 Pages

-

Heat Recovery—S-energy® EES

8 Pages

-

Sullair Vacuum System

8 Pages

-

1150XHH/1350XHDL

2 Pages

-

750XHH/900XHDL

2 Pages

-

TSR-20

2 Pages

-

TSR-32

2 Pages

-

DR-13

2 Pages

-

DR13

2 Pages

-

DE18

2 Pages

-

TSR20

2 Pages

-

RDHL

2 Pages

-

SSL10

16 Pages

Archived catalogs

-

shoptek

8 Pages

-

SULLAIR Air Treatment

30 Pages

-

ShopTek

8 Pages