Website:

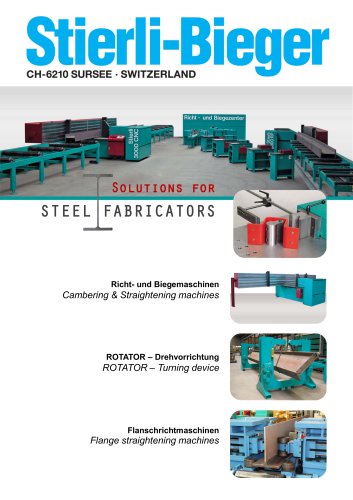

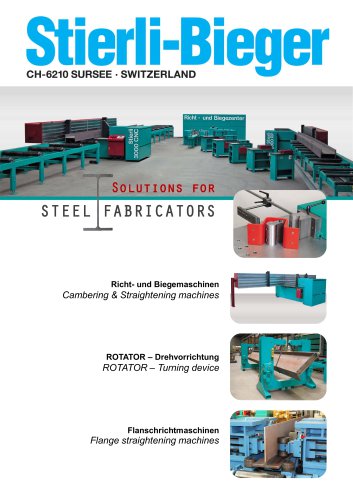

Stierli-Bieger AG

Website:

Stierli-Bieger AG

Catalog excerpts

Stierli-Bieger CH-6210 SURSEE • SWITZERLAND 120 CNC 220 CNC 420 CNC CNC-Busbar bending machine NEW Modern control system: The Stierl-Bieger bending center is a highly productive and versatile machine, available with a single axis or with an optional back gauge for a 2-axis system. Angle programming system, with tooling library The machine is programmed via the angle programing or the stroke length. In order to compensate for differences in material, the angle or stroke setting and the CNC back gauge position can be adjusted any time during the program in steps of +/- 0.1° or +/- 0.1mm. Bending with standard V-block Automatic angle correction: (optional) During the bending operation, the integrated encode system measures the angle of the bent part and re-bends if needed (automatic spring-back compensation). The required stroke and the spring-back compensation are each calculated by the control to achieve the best possible accuracy. Mark free bending possible with rotary bending jaws of the measuring prism

Open the catalog to page 1

Modern control system: Multiple-line display Software „Bend-Edit“ Powerful features „Bend-Edit“ Reports with „Bend-Edit“ with ethernet interface and readin / read-out of the programms to a external pc, laptop or ethernet network. Create infinite bending programs with removal to external PC, Laptop or ethernet network. Incl. backup function. Efficient creation of the bending programs with fast angle and leg length programming on secondary workstations. Automatic calculation of the stop positions using the integrated material library and K-factors. Calculation and display of the total length....

Open the catalog to page 2All Stierli-Bieger AG catalogs and technical brochures

-

RAIL BENDING

6 Pages

-

Solutions for SHIP BUILDING

4 Pages

-

CNC bending machine HYBRID

2 Pages

-

Busbars - bending machines

6 Pages

-

Main brochure

36 Pages

-

Solutions for Rail Bending

6 Pages

Archived catalogs

-

Solutions for Busbar Bending

6 Pages

-

brochure Stierli Bieger

12 Pages