Website:

SMI Group

Website:

SMI Group

Group: SMI Group

Catalog excerpts

AMY'S KITCHEN / EAUX VIVES / DEEM WATER / ALOYOUN WATER / CAMPARI AUSTRALIA AMY'S KITCHEN THE INNOVATIVE AND COMPACT HIGH-PERFORMANCE STRETCH-BLOW MOULDER

Open the catalog to page 1

4 C a n a d a : E a b i a : A l o m Wa t e r 0 ee Ar 2 0 Saudi Arabia: D pari gh hi der 6 Saudi : Cam ct l 3 pa ou 4 Australia ON EBS:and cohmblow m 4 G 2 New ERnovativcee stretc om 5 in ro an 68 thpeerform I's show new e 72

Open the catalog to page 2

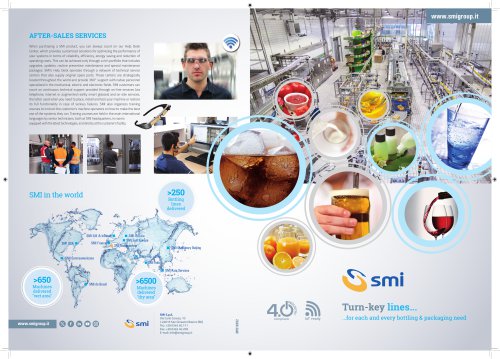

he efficiency of a company's bottling and packaging line is an essential part of the production process to improve its competitiveness in the food & beverage sector. This is why SMI's research and development projects of the past two years have focused on innovative ideas in the design and production of stretch-blow moulding, filling, packaging, palletizing and handling machines: concepts implemented by the new ERGON brand. All the new installations of the ERGON series feature compact, ergonomic and functional structures, simplifying the management, cleaning and maintenance of the machine,...

Open the catalog to page 3

SECTOR: FOOD AMY'S KITCHEN INC. Petaluma, California, USA www.amys.com SK 800 T Packer APS 3090 P - APS 1550 P Palletizers Turntable-based wrapper and conveyors

Open the catalog to page 4

AMY'S KITCHEN AMY'S KITCHEN I 5

Open the catalog to page 5

Good ideas comefrom the dinner table! As often happens, the best ideas are born at the table. That is exactly where an idea came up during a business meeting between SMI and the customer: that of creating a compact, multifunctional line whose heart is SMI's new pal/depal. From its very first meeting with Amy's Kitchen Inc. SMI felt and shared the pride of those who make a quality product, are aware of it and willing to tackle the issues on how to package it at best. This is how Amy's Project came to life. DISCUSSING REQUIREMENTS, PROBLEMS AND IDEAS AND COMING UP WITH A SOLUTION TOGETHER...

Open the catalog to page 6

An idea, a project, four operating modes depalletizing to ensure a better final quality of the product. How were we going to put together all these requirements and reduce the number of machines and manual operations? Sketch after sketch… the idea began to materialize, and at some point an OK appeared on an almost incomprehensible drawing…

Open the catalog to page 7

FROM THE IDEA TO THE PROJECT he production department is located upstream of the packaging line and comprises the cooking room, which they call the kitchen, and the can filling/ seaming system. Amy’s Kitchen has very high quality standards: in fact, if the cooking process stops for even just a few seconds, they discard the entire product batch being processed (approximately 45 minutes of production). Therefore, it goes without saying that an unexpected stop of the downstream packaging line will lead to a considerable waste of product and money for the customer. • Why have a great number of...

Open the catalog to page 8

MICHAEL MOODY, AMY'S SENIOR PLANT ENGINEER (ON THE LEFT) WITH ABEL SUAREZ, AMY'S CANNING MANAGER OREGON (IN THE MIDDLE) AND COREY PARRY, SALES AREA MANAGER OF SMI USA (ON THE RIGHT) AT AMY'S FACILITY IN MEDFORD, OREGON. The line end system that SMI installed at Amy's facility (which includes the APS 3090 P and APS 1550 automatic palletizers, the SK 800 T shrinkwrapper and the conveyors), features four different operating modes: 1. Non-labeled cans buffer mode 2. Labeled cans storage mode 3. Non-labeled cans storage mode 4. Depalletizing mode veloutf^" toniateSj solijw

Open the catalog to page 9

ORGANIC FOOD HELPS NATURE AND HEALTH For some time, we have known that something in this world's natural balance is falling apart and we need to find a remedy in some way or another. We can do that by purchasing organic food, products without polluting chemical additives, avoiding intensive livestock exploitation, working in full respect of the seasons and land rotation and subjecting the final product to the control of specific certification bodies. If you think that everything we eat or put on our skin, in the form of cosmetics, moulds our body and affects our brain, our metabolic...

Open the catalog to page 10

AMY'S KITCHEN GREAT KITCHEN Amy's Kitchen was founded in 1987, the year Amy was born, daughter of Rachel and Andy Berliner and founders of this important organic food company. Thanks to Andy and Rachel's meticulous teamwork, they keep coming up with new ideas year a_fter year, submitting them to Amy's Kitchen cooks. They never get tired of trying or retrying new recipes, until ideas turn into new products that are placed on the market, only after extensive quality testing. Thanks to Rachel's attentive and sensitive palate, she is the company's official taster. Extreme product care,...

Open the catalog to page 11

mAHH I NON-LABELED CANS BUFFER MODETHE APS 3090 P PALLETIZER WORKS AS A PALLETIZING + PALLET WRAPPING SYSTEM FOR FINISHED PRODUCT WITH CORNER-INSERTERS, WHEREAS THE APS 1550 P PALLETIZER WORKS AS A BUFFER FOR NON-LABELED CANS. APS 1 SbO PAL & DEPAL SYSTEM APS 3090 - PAllfcT WRAPPING SYSTEM . CORNER-BOARD APPLICATOR Product flow during normal operation Product flow in the event the downstream line stops: the APS 1550 P works in palletizing mode by accumulating product and allowing the kitchen not to slop. This is the main operating mode of Amy’s production line. The point on the...

Open the catalog to page 12

of the palletizing system is equipped with a device that applies some cardboard corners before wrapping the stretch film. These corners are applied both to strengthen the pallet and make it suitable also for intercontinental transport. If a stop occurs downstream of the kitchen while the system works in mode 1, the product will be diverted to the buffer system. As highlighted in red in the layout, a pneumatically operated guide diverts the cans that were just placed on the chained belts and places them on a belt (point 3) where they are naturally distributed to form a layer. This is...

Open the catalog to page 13

2. LABELED CANS STORAGE MODE THE APS 1550 P PALLETIZER WORKS AS A BUFFER FOR LABELED CANS Product flow during labeled cans storage mode Product flow in the event the downstream line stops: the APS 1550 P works in palletizing mode by accumulating product and allowing the kitchen not to stop hen this operating mode is selected, the APS 3090 P palletizer does not work, whereas the APS 1550 P model works as labeled cans palletizer. This operating mode allows the customer to increase stock availability of labeled products in order to package them in film or tray later on. The green path on the...

Open the catalog to page 14All SMI Group catalogs and technical brochures

-

Cartesian palletizer

2 Pages

-

SMI NOW 26/2023

80 Pages

-

TPP PACKER BROCHURE

2 Pages

-

SMI NOW 25/2022

68 Pages

-

Cartesian palletizer

21 Pages

-

AUTOMATIC PACKERS

48 Pages

-

BLOWING & FILLING

28 Pages

-

Company Profile 2023

24 Pages

-

SMI NOW 24/2021

84 Pages

-

SMI NOW 23/2020

76 Pages

-

CONVEYOR BELTS

8 Pages

-

Smypass priority

12 Pages

-

AR Smart Glasses

2 Pages

-

SMI NOW 22/2019

84 Pages

-

SMI NOW 20/2018

84 Pages

-

SMI NOW 19/2018

80 Pages

-

SMI NOW 21/2019

84 Pages

-

SMI NOW 18/2017

84 Pages

-

SMI NOW 17/2017

84 Pages

-

SMI NOW 15/2015

92 Pages

-

SMI NOW 14/2015

80 Pages

-

SMI NOW 13/2014

80 Pages

-

Smi Now magazine 11/2013

76 Pages

-

SMI NOW 12/2014

76 Pages

-

Smi Now magazine 10/2013

68 Pages

-

SMI NOW 08/2012

76 Pages

-

SMI NOW 09/2012

68 Pages

Archived catalogs

-

SMI Turn-key lines

2 Pages