Website:

SMC PNEUMATIC

Website:

SMC PNEUMATIC

Group: SMC

Catalog excerpts

Precautionary measures against condensation in a pneumatic system (Phenomena, process, prediction and preventive measures) In a pneumatic system, temperature drops may cause internal condensation under certain piping and operating conditions, leading to malfunction and reduced life time due to deterioration and the washing out of grease. This brochure provides useful information on countermeasures and preventive actions to be taken in this regard. P-E01-11B

Open the catalog to page 1

Contents Page 1. Condensation phenomenaȵȵȵȵȵȵȵȵȵȵȵȵȵȵȵȵȵȵȵȵȵȵȵȵȵȵȵȵȵȵȵȵȵȵȵȵȵȵȵȵȵȵȵ 1 What is condensation in a pneumatic system? What kind of problems can it bring about? 2. Process of condensationȵȵȵȵȵȵȵȵȵȵȵȵȵȵȵȵȵȵȵȵȵȵȵȵȵȵȵȵȵȵȵȵȵȵȵȵȵȵȵȵȵȵȵȵȵ 2 2-1 Adiabatic expansion 2-2 Process of condensation 3. Condensation assessmentȵȵȵȵȵȵȵȵȵȵȵȵȵȵȵȵȵȵȵȵȵȵȵȵȵȵȵȵȵȵȵȵȵȵȵȵȵȵȵȵȵȵȵ 5 3-1 Condensation assessment chart 3-2 Condensation assessment program 4. Countermeasures against condensationȵȵȵȵȵȵȵȵȵȵȵȵȵȵȵȵȵȵȵȵȵȵȵȵȵȵȵȵȵ 7 5. Supplementȵȵȵȵȵȵȵȵȵȵȵȵȵȵȵȵȵȵȵȵȵȵȵȵȵȵȵȵȵȵȵȵȵȵȵȵȵȵȵȵȵȵȵȵȵȵȵȵȵȵȵȵȵȵȵȵȵȵ 9 Dew point...

Open the catalog to page 3

1. Condensation phenomena Ȝ What is condensation in a pneumatic system? In a pneumatic system, waterdrops sometimes form inside piping, affecting operation and the life of equipment. For this reason, compressed air is usually dehumidified with an air dryer before being supplied to the system. However, due to increasing demand for smaller, faster equipment, even the use of dehumidified air may result in condensation and consequent failure when a small actuator is used. Photo 1 shows condensation occurring inside a piping, and Photo 2 shows the dripping of condensation in a cylinder. Water...

Open the catalog to page 4

2. Process of condensation The following is an example of a small cylinder drive system illustrating a condition under which condensation occurs inside a piping. 2-1 Adiabatic expansion Results of temperature measurement inside the piping Tl = (Ts+273) x ( 0.1 Ps+0.1 ) 0.286 –273 When the air at 27°C and 0.5 MPa undergoes adiabatic expansion to atmospheric pressure, theoretically the temperature will drop to nearly –93°C. Actual temperature measurements inside the piping in the right chart show that the temperature dropped to approximately –80°C. Temperature of supplied air: 20°C Gauge...

Open the catalog to page 5

[Temperature drop -» Mist formation] The solenoid valve is switched and air inside the piping is instantly released. Then, the pressure inside the piping is reduced suddenly (adiabatic expansion), causing the temperature to drop. If the atmospheric dew point of the supply air is Tt (°C), and the temperature drop of the air Ti (°C) after adiabatic expansion falls below this value (77 < Tt), then mist formation occurs. Mist formation Cylinder Piping (tube) Solenoid Exhaust [Mist evaporation and small amount of residual mist] Most of the mist is discharged through evaporation by the...

Open the catalog to page 6

[Volume of the piping is large (long piping) —> Mist accumulation] When the cylinder is small and the piping is long (that is, the volume of the piping is larger than that of the cylinder), air inside the cylinder cannot be exhausted at the time of release and remains inside the piping. Mist cannot be exhausted Piping (tube) Solenoid Exhaust If the volume of the piping is smaller than the volume of the cylinder, the mist will be exhausted with the exhausted air as shown in the figure below, and the mist will not accumulate inside the piping. As the cylinder cycles, the mist accumulating...

Open the catalog to page 7

The probability of condensation is influenced mainly by the volume ratio, humidity and pressure of the supply air, etc. The following chart and program are provided for assessing more specific cases. 3-1 Condensation assessment chart I [condition] Switching intervals of solenoid valve: ON 1 sec, OFF 1 sec. Piping tube material: Polyurethane Range in which condensation occurs Range in which condensation does not occur Enlarged chart

Open the catalog to page 8

How to use the chart (Refer to page 5) (1) Find the atmospheric dew point of inlet air ©. When the humidity of inlet air can be considered as relative humidity or a pressure dew point, the atmospheric dew point can be found according to the humidity conversion chart in "Humidity and conversion" page 10 of the supplement. (2) Find the volume ratio Kv ®. Find the volume ratio from the following equation for a volume ratio. Vt: Volume inside the piping [cm3] Ps : Gage pressure of supplied air [MPa] (3) Assess the probability of condensation. Extend lines from © to (?) and from © to © to find...

Open the catalog to page 9

ketro-B-P07.qxd 10.12.27 1:31 PM Page 1 4. Countermeasures against condensation Based on the above-mentioned condensation example, the following preventive measures can be implemented. Ȝ Countermeasures against air quality Compressed air containing a large amount of moisture condenses easily and may cause the pneumatic equipment to malfunction. Therefore, it is recommended to install an air dryer before pneumatic equipment, based on the results of the Condensation Assessment Chart or the SMC Model Selection Software. For selecting the air dryer, refer to the SMC Pneumatic Energy Saving...

Open the catalog to page 10

© By-pass circuit method Sufficient exchange of air can be achieved by providing one-way air supply and exhaust circuits with check valves and by-pass piping. By-pass piping installation position Li: it should be smaller than -g— x —QT~ and be installed as close to the cylinder as possible. Length of by-pass piping L2: approx. 20% of the total length of L Solenoid valve Check valve Sp : Piping cross-sectional area [mm2] Check Valve with One-touch Fitting Straight type (D Quick exhaust valve method Install quick exhaust valves close to the cylinder to exhaust air inside the cylinder directly...

Open the catalog to page 11

The content of vapor in air is represented by the humidity or dew point. Absolute humidity : The mass ratio of vapor to dry air Relative humidity : The mass ratio of vapor to amount of saturated vapor Atmospheric pressure dew point : Temperature at which vapor reaches saturation when air is cooled under atmospheric pressure. Pressure dew point: Temperature at which vapor reaches saturation when air is cooled under fixed pressure. Humidity conversion diagram Relative humidity % How to use the humidity conversion chart Top-left chart: Top-right chart: Used for conversion between relative...

Open the catalog to page 13All SMC PNEUMATIC catalogs and technical brochures

-

SYJ300/500/700 Series

62 Pages

-

Vacuum Unit ZK2 Series

60 Pages

-

Air Cylinder CJ2 Series

117 Pages

-

AS-FS Series

36 Pages

-

IDF series

12 Pages

-

MHL2 Series

24 Pages

-

JCM Serie

18 Pages

-

EX245 Series

12 Pages

-

Pin Cylinder CJP2/CDJP2/CJP

19 Pages

-

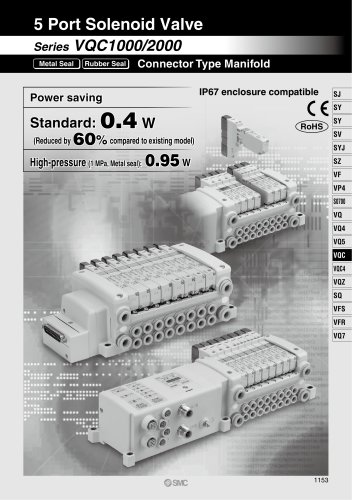

5 Port Solenoid Valve VQC

63 Pages

-

5 Port Solenoid Valve VQ

79 Pages

-

SY

268 Pages

-

5-p0979-0980-hep500

2 Pages

-

5-p0977-0978-aep100

2 Pages

-

5-p0966-0971-lmu

5 Pages

-

5-p0960-0966-alb900

6 Pages

-

5-p0956-0960-ald600

5 Pages

-

5-p0948-0950-al800

3 Pages

-

es70-44c-vx2

52 Pages

-

es50-37-kq2

124 Pages

-

ex-pcw

23 Pages

-

1-p2124-2152-ex510

29 Pages

-

1-p2111-2122-ex500

12 Pages

-

1-p2063-2073-ex260

11 Pages

-

4-p0147-0178-msu-mds

32 Pages

-

es20-230b-crb2

59 Pages

-

1-p1869-1878-vp3145

10 Pages

-

VP300/500/700 series

42 Pages

-

1-p1789-1829-vqz100

41 Pages

-

1-p1727-1788-syj300

62 Pages

-

5 Port Solenoid Valve S0700

111 Pages

-

5 Port Solenoid Valve VF

59 Pages

-

5 Port Solenoid Valve SV

127 Pages

-

VH

9 Pages

-

CUJ

41 Pages

-

AL

3 Pages

-

kj mm

9 Pages

-

AQ

4 Pages

-

SY3000/5000-X13

2 Pages

-

Series MB

24 Pages

-

Series LES

23 Pages

-

Series LEFB

16 Pages

-

Series PF3W

28 Pages

-

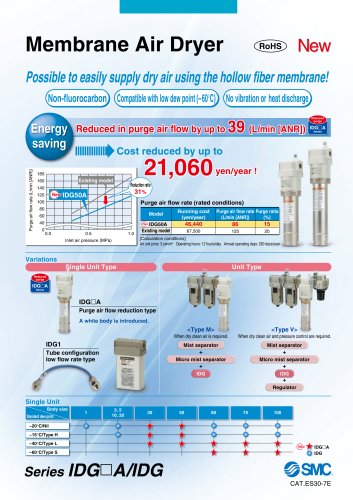

Series IDG?A/IDG

56 Pages

-

Floating Joint

7 Pages

-

Series IZS40/41/42

32 Pages

-

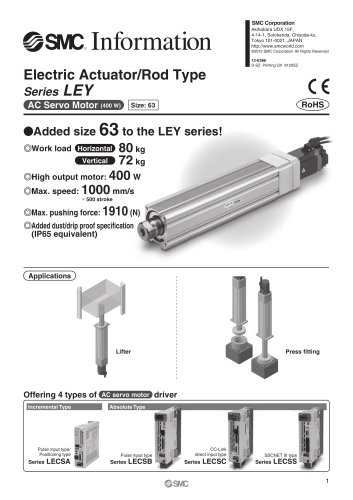

Series LEY

7 Pages

-

Series VHS

12 Pages

-

Series CY1S

28 Pages

-

SeriesCQ2/CQS/CQ

4 Pages

-

In-line Air Filter

12 Pages

-

5 Port Solenoid Valve

60 Pages

-

Series CQ2/CQS

2 Pages

-

AS series

2 Pages

-

corporate guide

13 Pages

-

ZP

69 Pages

-

ZFA

14 Pages

-

ZA

13 Pages

-

MHF

32 Pages

-

MHZ

68 Pages

-

CRB

44 Pages

-

D

117 Pages

-

RB

23 Pages

-

CEP

44 Pages

-

RSK

30 Pages

-

CLK

51 Pages

-

MK

20 Pages

-

GLJ

65 Pages

-

MGJ

7 Pages

-

Mx

36 Pages

-

MXH

18 Pages

-

My3

56 Pages

-

my1b

20 Pages

-

CC

15 Pages

-

J

14 Pages

-

CQ2

51 Pages

-

standard cylinder

84 Pages

-

VFN

6 Pages

-

SY3000

246 Pages

-

SJ3A6

18 Pages

-

1301/IW

14 Pages

-

CHQ/CHDQ

19 Pages

-

AC

95 Pages

-

HAW

4 Pages

-

HAA

3 Pages

-

ZB

24 Pages

-

CRB2

35 Pages

-

CJ1

5 Pages

-

SYJ

62 Pages

-

SJ

78 Pages