Website:

SMC PNEUMATIC

Website:

SMC PNEUMATIC

Group: SMC

Catalog excerpts

Water Cooled Aftercooler Series HAW can cool high Model/Standard Specifications from compressors down to remove moisture from the cooled, it can be used where there is high temperature, high moisture and heavy foreign particles. 25 times heat transfer area As compared to shell and bare tube, the flower fin tube has 25 times the heat transfer area. Even heat exchange Sharp edge of flower fin causes air turbu- lence resulting in even heat exchange and high cooling efficiency. High efficiency drain Drainage is efficiently removed by built-in drain separator. Visible outlet air temperature Outlet air temperature is easily checked by thermometer, resulting in easy mainte- Note 1 ) ANR indicates the flow rate converted to the value at 20°C under the atmospheric pressure and the state of relative humidity 65%. Note 2) The accessories should be mounted by user. Accessory (Option) Conditions: • Supply pressure 0.7 MPa, Outlet air temperature 40°C, Cooling water Inlet temperature 30°C • Inlet air temperature 50°C is saturated air. At 70°C or more, it is humid air with dew point 67°C

Open the catalog to page 1

Basic size Accessory (Option Port size How to Calculate Outlet Air Temperature Outlet air temperature can be calculated with Inlet air temperature, cooling water tempera- ture and amount of air in the following proce- (Example) Inlet air temperature: 100°C, Cooling water temperature: 20°C, Cooling Outlet air temperature at above conditions (1) Use outlet air temperature of 37°C from I outlet air temperature table. At this time I correction factor line becomes ®. (2) To get correction factor of 1.3 use cooling I water temperature correction factor ® at (3) To get outlet air temperature...

Open the catalog to page 2

Water Cooled Aftercooler Construction Principle tube assembly Flow Characteristics (Example) To get pressure drop at 0.3 MPa from the table and convert Pi to Replacement Parts Note) Chart shows HAW22 to 75. it differs from the above graph. Replacement Parts Note) Note) Consult with SMC when replacing parts since special tools are required

Open the catalog to page 3All SMC PNEUMATIC catalogs and technical brochures

-

SYJ300/500/700 Series

62 Pages

-

Vacuum Unit ZK2 Series

60 Pages

-

Air Cylinder CJ2 Series

117 Pages

-

AS-FS Series

36 Pages

-

IDF series

12 Pages

-

MHL2 Series

24 Pages

-

JCM Serie

18 Pages

-

EX245 Series

12 Pages

-

Pin Cylinder CJP2/CDJP2/CJP

19 Pages

-

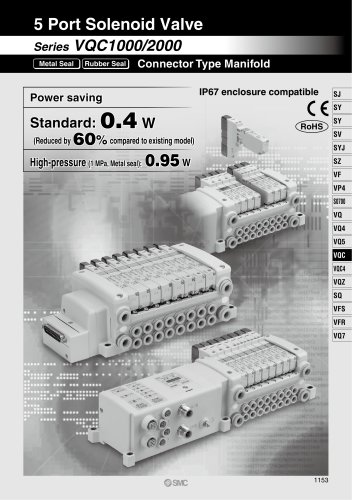

5 Port Solenoid Valve VQC

63 Pages

-

5 Port Solenoid Valve VQ

79 Pages

-

SY

268 Pages

-

5-p0979-0980-hep500

2 Pages

-

5-p0977-0978-aep100

2 Pages

-

5-p0966-0971-lmu

5 Pages

-

5-p0960-0966-alb900

6 Pages

-

5-p0956-0960-ald600

5 Pages

-

5-p0948-0950-al800

3 Pages

-

es70-44c-vx2

52 Pages

-

es50-37-kq2

124 Pages

-

ex-pcw

23 Pages

-

1-p2124-2152-ex510

29 Pages

-

1-p2111-2122-ex500

12 Pages

-

1-p2063-2073-ex260

11 Pages

-

4-p0147-0178-msu-mds

32 Pages

-

es20-230b-crb2

59 Pages

-

1-p1869-1878-vp3145

10 Pages

-

VP300/500/700 series

42 Pages

-

1-p1789-1829-vqz100

41 Pages

-

1-p1727-1788-syj300

62 Pages

-

5 Port Solenoid Valve S0700

111 Pages

-

5 Port Solenoid Valve VF

59 Pages

-

5 Port Solenoid Valve SV

127 Pages

-

VH

9 Pages

-

CUJ

41 Pages

-

AL

3 Pages

-

kj mm

9 Pages

-

AQ

4 Pages

-

SY3000/5000-X13

2 Pages

-

Series MB

24 Pages

-

Series LES

23 Pages

-

Series LEFB

16 Pages

-

Series PF3W

28 Pages

-

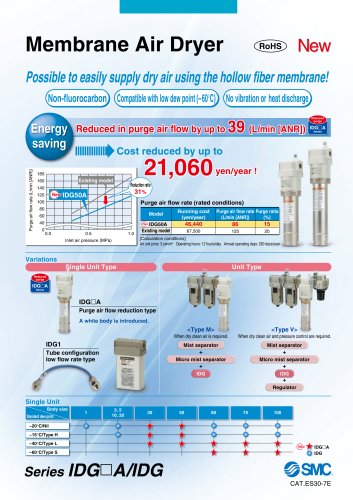

Series IDG?A/IDG

56 Pages

-

Floating Joint

7 Pages

-

Series IZS40/41/42

32 Pages

-

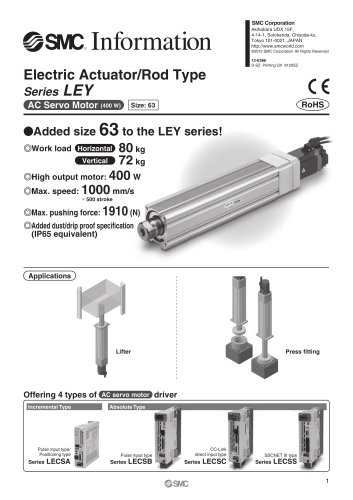

Series LEY

7 Pages

-

Series VHS

12 Pages

-

Series CY1S

28 Pages

-

SeriesCQ2/CQS/CQ

4 Pages

-

In-line Air Filter

12 Pages

-

5 Port Solenoid Valve

60 Pages

-

Series CQ2/CQS

2 Pages

-

AS series

2 Pages

-

corporate guide

13 Pages

-

ZP

69 Pages

-

ZFA

14 Pages

-

ZA

13 Pages

-

MHF

32 Pages

-

MHZ

68 Pages

-

CRB

44 Pages

-

D

117 Pages

-

RB

23 Pages

-

CEP

44 Pages

-

RSK

30 Pages

-

CLK

51 Pages

-

MK

20 Pages

-

GLJ

65 Pages

-

MGJ

7 Pages

-

Mx

36 Pages

-

MXH

18 Pages

-

My3

56 Pages

-

my1b

20 Pages

-

CC

15 Pages

-

J

14 Pages

-

CQ2

51 Pages

-

standard cylinder

84 Pages

-

VFN

6 Pages

-

SY3000

246 Pages

-

SJ3A6

18 Pages

-

1301/IW

14 Pages

-

CHQ/CHDQ

19 Pages

-

AC

95 Pages

-

HAA

3 Pages

-

ZB

24 Pages

-

CRB2

35 Pages

-

CJ1

5 Pages

-

SYJ

62 Pages

-

SJ

78 Pages