Website:

SMC PNEUMATIC

Website:

SMC PNEUMATIC

Group: SMC

Catalog excerpts

Converting pneumatic pressure to hydraulic pressure (equivalent pressure) solves cylinder problems occurring due to the compression characteristics of pneumatic pressure. • Constant-speed operation is possible with load fluctuations. • Solves the problems of sticking and slipping associated with low-speed operation. • Intermediate stopping and skip movement possible. • Suitable for slow operation of a rotary actuator. Integrate a converter and a valve unit in a compact configuration. • Possible to select 4 types of valve units for applications. • Possible to connect a converter and a valve unit independently. Wide range of series in terms of converter capacity and valve unit flow rate control capability. • Compatible with cylinder bore sizes up to 0300. • Operation at a piston speed of 180 mm/sec with a size 08O cylinder bore. (Operating pressure: 0.5 MPa, Load mass: No load, Piping: I.D. o19 mm x length 1 m) Air-hydro Unit Air-hydro Converter Valve Unit Series CCVS/CCVL Application Example 1. Function of stop valve Prevents load dropping (In an emergency) 2. Function of skip valve Fast forward to working process Multipoint intermediate stops 3. Flow control valve (With pressure compensation) Uniform driving for load fluctuations (Not only solid but also liquid is available if there is pump mechanism at the end.) 4. Throttle valve/Speed controller • Working without jumping at low speeds or when starting. • Control with throttle valve and speed controller when transferring and carrying.

Open the catalog to page 1

Selection Procedure Step (1) Select the bore size of air-hydro cylinder First of all, select a bore size from data (D) <Theoretical Output Table>. When making a selection, the ratio between the theoretical output and the load should be 0.5 or less. Step (2) Select converter_ Select the nominal diameter and the effective oil level stroke from data (A), <Cylinder Displacement and Converter Capacity Diagram>. When selecting a converter by its nominal diameter, the converter's oil level speed should be Step (3) Select required function for valve unit Select a model from data (B), <Converter and...

Open the catalog to page 2

P0923-P0938-E.qxd 08.10.3 2:15 PM Page 925 Air-hydro Unit Series CC Data (A) Volume of Cylinder/Capacity of Converter 800 700 600 500 400 300 200 00 10,000 8,000 ø3 0 5 ø2 0 ø20 ø180 ø160 ø140 ø80 6,000 5,000 4,000 600 500 ø63 3,000 400 ø50 2,000 Effective oil level stroke (mm) 300 200 ø125 ø100 ø40 500 300 100 200 300 100 200 150 Capacity of converter (cm3) 400 1,000 800 ø30 ø25 CRA1H100-180 ø20 600 500 400 CRA1H100-90 300 CRA1H80-180 200 CRA1H80-90 CRA1H63-180 50 100 100 80 CRA1H63-90 CRA1H50-180 60 50 40 50 CRA1H50-90 30 160 100 63 20 40 100 200 300 400 500 600 700 800 Selected model of...

Open the catalog to page 3

Data (C) Maximum Driving Speed of Valve Unit and Cylinder Cylinder driving speed when operating flow control valve Cylinder driving speed when operating throttle valve Cylinder driving speed when operating stop valve Condition: Operating press.: 0.3 to 0.7 MPa Load ratio: 50% or less Operating oil: Additive turbine oil Class 1 Piping bore Piping bore Piping bore ^Caution on Circuit Construction I.The converter's oil level must be properly maintained because a slight oil leak from the sliding of the seal of the air-hydro 2. Make sure to install an exhaust cleaner (Series AMC/Best Pneumatics...

Open the catalog to page 4

Air-hydro Unit Series CC Data (D) Theoretical Output A Caution on Circuit Construction Skip valve 1. When using a skip valve, the maximum allow- able ratio between the high speed and the low speed is approximately 3:1. If this ratio is too large, air bubbles could form due to cavitations, and could lead to the conditions described in Product Specific Precautions (page 936). 2. If the skip valve of an air-hydro unit with skip valve is operated, because it is not equipped with a speed control valve, the fast-forward speed will be determined by the model, piping conditions, and the actuator...

Open the catalog to page 5

Air-hydro Unit The air-hydro unit consists of a converter and a valve unit that are compactly integrated. It converts air pressure to an equivalent hydraulic pressure, and this hydraulic pressure is used for operating an actuator, thus solving the problem that is associated with the compression characteristics of air. Thus, in spite of using pneumatic equipment, it performs similarly to a hydraulic unit, operating at a constant speed during starting or in the presence of load fluctuations, and at the same time solving the problems of sticking and slipping associated with low speed...

Open the catalog to page 6

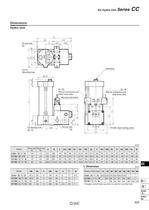

Air-hydro Unit Series CC Hydro Unit ■ Hexagon socket head cap screw is used for mounting hole.

Open the catalog to page 7

Air-hydro Converter Effective oil level stroke (mm) Converter nominal size/stroke (mm) Converter Standard Effective Oil Level Stroke/Effective Volume (cm3) ♦ Limited flow shows the limit of converter oil level speed (200 mm/s) which can maintain stability of Effective oil level stroke converter for an actuator with a small capacity, it cannot be made into an air-hydro unit. valve unit or a speed Converter Standard Effective Oil Level Stroke/Effective Volume ♦ Limited flow shows the limit of converter oil level speed (200 mm/s) which can maintain stability of

Open the catalog to page 8

Air-hydro Converter Series CCT hexagon socket head * Hexagon socket head cap screw is used for mounting. L Dimension (Effective oil level stroke)

Open the catalog to page 9

Valve Unit Seríes CCVS/CCVL CCVS/CCVL Valve Unit Part No. Combinations Valve unit size Control valve Combined valve combined valve (0), solenoid valve does not come with. Electrical entry of solenoid valve Solenoid valve rated voltage

Open the catalog to page 10

Valve Unit Series CCVS/CCVL Solenoid Valve Specifications of Combined Valve (Stop valve/Skip valve) Applicable Converter Solenoid Valve Function Plate t Valve opens when solenoid valve conducts * Valve opens when solenoid valve stops conducting electricity. * Pitch of mounting on the wall is CA and CL.

Open the catalog to page 11All SMC PNEUMATIC catalogs and technical brochures

-

SYJ300/500/700 Series

62 Pages

-

Vacuum Unit ZK2 Series

60 Pages

-

Air Cylinder CJ2 Series

117 Pages

-

AS-FS Series

36 Pages

-

IDF series

12 Pages

-

MHL2 Series

24 Pages

-

JCM Serie

18 Pages

-

EX245 Series

12 Pages

-

Pin Cylinder CJP2/CDJP2/CJP

19 Pages

-

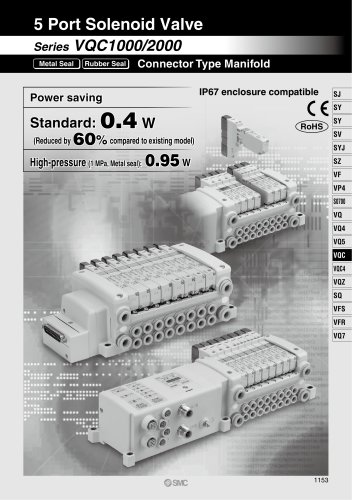

5 Port Solenoid Valve VQC

63 Pages

-

5 Port Solenoid Valve VQ

79 Pages

-

SY

268 Pages

-

5-p0979-0980-hep500

2 Pages

-

5-p0977-0978-aep100

2 Pages

-

5-p0966-0971-lmu

5 Pages

-

5-p0960-0966-alb900

6 Pages

-

5-p0956-0960-ald600

5 Pages

-

5-p0948-0950-al800

3 Pages

-

es70-44c-vx2

52 Pages

-

es50-37-kq2

124 Pages

-

ex-pcw

23 Pages

-

1-p2124-2152-ex510

29 Pages

-

1-p2111-2122-ex500

12 Pages

-

1-p2063-2073-ex260

11 Pages

-

4-p0147-0178-msu-mds

32 Pages

-

es20-230b-crb2

59 Pages

-

1-p1869-1878-vp3145

10 Pages

-

VP300/500/700 series

42 Pages

-

1-p1789-1829-vqz100

41 Pages

-

1-p1727-1788-syj300

62 Pages

-

5 Port Solenoid Valve S0700

111 Pages

-

5 Port Solenoid Valve VF

59 Pages

-

5 Port Solenoid Valve SV

127 Pages

-

VH

9 Pages

-

CUJ

41 Pages

-

AL

3 Pages

-

kj mm

9 Pages

-

AQ

4 Pages

-

SY3000/5000-X13

2 Pages

-

Series MB

24 Pages

-

Series LES

23 Pages

-

Series LEFB

16 Pages

-

Series PF3W

28 Pages

-

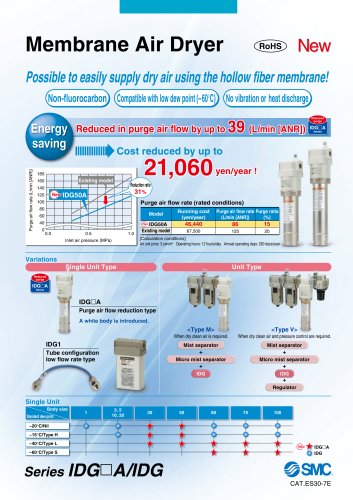

Series IDG?A/IDG

56 Pages

-

Floating Joint

7 Pages

-

Series IZS40/41/42

32 Pages

-

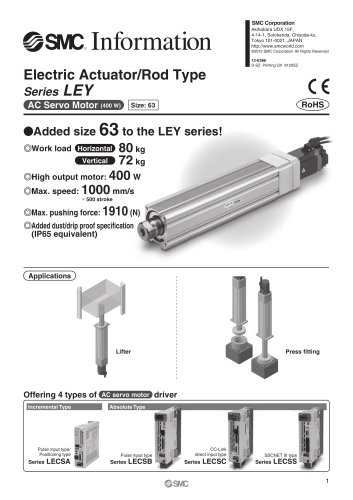

Series LEY

7 Pages

-

Series VHS

12 Pages

-

Series CY1S

28 Pages

-

SeriesCQ2/CQS/CQ

4 Pages

-

In-line Air Filter

12 Pages

-

5 Port Solenoid Valve

60 Pages

-

Series CQ2/CQS

2 Pages

-

AS series

2 Pages

-

corporate guide

13 Pages

-

ZP

69 Pages

-

ZFA

14 Pages

-

ZA

13 Pages

-

MHF

32 Pages

-

MHZ

68 Pages

-

CRB

44 Pages

-

D

117 Pages

-

RB

23 Pages

-

CEP

44 Pages

-

RSK

30 Pages

-

CLK

51 Pages

-

MK

20 Pages

-

GLJ

65 Pages

-

MGJ

7 Pages

-

Mx

36 Pages

-

MXH

18 Pages

-

My3

56 Pages

-

my1b

20 Pages

-

J

14 Pages

-

CQ2

51 Pages

-

standard cylinder

84 Pages

-

VFN

6 Pages

-

SY3000

246 Pages

-

SJ3A6

18 Pages

-

1301/IW

14 Pages

-

CHQ/CHDQ

19 Pages

-

AC

95 Pages

-

HAW

4 Pages

-

HAA

3 Pages

-

ZB

24 Pages

-

CRB2

35 Pages

-

CJ1

5 Pages

-

SYJ

62 Pages

-

SJ

78 Pages