Website:

Simco-Ion

Website:

Simco-Ion

Group: ITW

Catalog excerpts

Platform for controlling static 4 electricity / IQ Easy platform Static elimination 9 Ionising air blowers / Airknives 19 Charging bars / Charging electrodes 29 IML 30 Mission Simco-Ion® Netherlands manufactures and supplies complete solutions for static control, static charging, surface cleaning, static measuring, perforation detection and IML applications in Europe, Africa and the Middle East. Our goal is to grow our business by being the highest value provider for our customers. We provide value through a combination of advanced technology, a full line of products, superior...

Open the catalog to page 2

What can you expect from Simco-Ion? Explanation of symbols Static Measuring A solid advice: More than 60 employees in 35 countries across EMEA provide an enormous range and wealth of application knowledge to help you optimize your processes. An efficient solution for: - Neutralisation of static charge - Application of static charge - Surface cleaning - Perforation detection - Measuring static charge - IML Static Elimination Static Bonding - Customer service - After sales support - 4 year warranty - International support - Efficient - Durable - High quality - 4 year warranty Contact Surface...

Open the catalog to page 3

What makes this system better? Even very low static charges can cause a problem in processing film for high-tech products. Simco-Ion provides a solution to these challenges. The demands from our customers are increasingly higher with regards to control and efficiency of anti-static equipment. Their end customer expects a very high quality product with very little, or no, static charge. These customers produce e.g. High quality film for electronics, medical applications or food packaging. Conventional anti-static equipment does a very good job up to a certain level. Optimal neutralisation...

Open the catalog to page 5

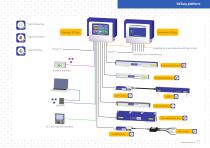

Information is colour coded What kind of interfaces are available? O Human interface via touchscreen O Standard analogue and digital I/O ports O Fieldbus, e.g. ProfiBus O Ethernet O USB Action logging The IQ Easy platform makes it easy to control all Simco-Ion-devices in a production process. Independent of their function, whether it is an anti-static bar, charging generator, perforation detector or measuring device, they can all communicate with the Manager IQ Easy, the heart of the new IQ Easy platform. The IQ Easy system is unique because all devices form a system and not as before all...

Open the catalog to page 6

Static Measuring Static Elimination Static Bonding Possibility for max 4 Extensions IQ Easy in total Power in Possibility for 6 more devices Performax IQ Easy Ex Fieldbus interface Performax IQ Easy ThunderION IQ 2.0 PLC (I/O machine interface) CMM IQ Easy

Open the catalog to page 7

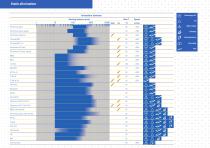

Performax IQ Easy Ex ThunderlON IQ 2.0 CM Tiny IQ Sensor IQ Easy Efficiency indication Data logging Action logging Remote control Warning output Alarm output CLFB (with Sensor) Web voltage too high Warning Web voltage too high Alarm Temperature too high Alarm Ionisation current indication Voltage control Current control Voltage setpoint Current setpoint

Open the catalog to page 8

Static elimination For each process the perfect solution for static electricity control www.simco-ion.nl www.simco-ion.nl

Open the catalog to page 9

Static elimination Static elimination Static electricity can be troublesome in many production processes where non-conductive materials such as plastic, paper, wood and textile are processed. How do you know if in your situation static electricity plays a role? Most common problems are easy to recognise: Sparks jump over Materials cling together and are difficult to process What causes static charge? Static charge is mainly caused by friction and separation of poorly conducting materials. Static charge can be demonstrated by measuring with an electrostatic fieldmeter. See the section...

Open the catalog to page 10

Static elimination What do ionisers looks like and which one is right for my application? Ionisers are available in different sizes and shapes. The choice depends on the application and a number of distinguishing features: gg Technology (external power supply , or integrated high voltage 24V) gg Working distance gg Material velocity gg Object To be neutralised, 3D product or flat material web gg Environmental conditions, temperature, humidity, Atex zone gg Inspections Typical applications examples: ThunderION on roll (different diameters) Gun on object (plate, bumper) Airknife/Typhoon...

Open the catalog to page 11

Static elimination Ionisation devices High voltage Cleaning jHand operation 6) Conveying

Open the catalog to page 12

What is the difference between ionisers? Anti-static bar with separate high voltage generator: Anti-static bar with built-in high-voltage: Universal mounting: Advantages: o Anti-static bars are very compact O Up to 4 ionising devices can be connected to the power supply Disadvantages: O Large power supply, takes a lot of space O Rigid high-voltage cable that has to be mounted correctly O Fixed connection of the high-voltage cable O Fixed length of the high-voltage cable, cannot be shortened O No indication of the operation O Proper power supply device and input power should...

Open the catalog to page 13

Performax Easy and Performax Easy speed In combination with the Manager IQ Easy the Performax IQ Easy anti-static bar will ensure a very high efficiency of static neutralisation. Adding a Sensor IQ Easy to the system enhances the efficiency by measuring the downstream residual static charge and regulating the ionisation efficiency in real time to ensure a very low residual static charge. Features: O Neutralisation at speeds of >500 m/min (speed version) O Closed-loop feedback ionisation in association with Sensor IQ Easy* O Efficiency indication* O Minimal risk of deflection and...

Open the catalog to page 14

ThunderlON 2.0 The ThunderlON 2.0 has the same features as the ThunderlON, however the totally new designed housing makes it very easy to clean the ThunderION 2.0. End brackets, middle support brackets, side plates and emitters can be easily removed to gain access to the whole surface for fast and accurate cleaning. Features: O Long working distance: 300-1000 mm O Incorporated high voltage power supply, input voltage 24V DC O Shockless touchable emitters O Minimal risk of deflection and deformation of the anti-static bar due to reinforced plastic profile O Easy to clean O Visual indications...

Open the catalog to page 15All Simco-Ion catalogs and technical brochures

-

HDC

1 Pages

-

BlowflexEasySpot

1 Pages

-

VicinION

1 Pages

-

CMTiny

1 Pages

-

ThunderIONIQ2Overview

1 Pages

-

IML Easycore

1 Pages

-

HP-N-Ex

2 Pages

-

HD DET

1 Pages

-

CMME

1 Pages

-

BlowION

1 Pages

-

Performax Easy

1 Pages

-

Manager IQ Easy

4 Pages

-

P-Sh-N

1 Pages

-

MaxION

1 Pages

-

MEJ

1 Pages

-

ThunderION 2.0

2 Pages

-

Flat Nozzle

2 Pages

-

TensION

1 Pages

-

FMX-004

1 Pages

-

Performax Easy

2 Pages

-

Sensor IQ Easy

2 Pages

-

Perfomaster

1 Pages

-

Extension IQ Easy

3 Pages

-

Performax IQ Easy

2 Pages

-

ChargeMaster Tiny (CM Tiny)

2 Pages

-

Typhoon

2 Pages