Website:

sia Abrasives

Website:

sia Abrasives

Catalog excerpts

Wood Finishing systems for solid wood, wood-based materials and varnishes

Open the catalog to page 1

sia Abrasives – Your key to a perfect surface Many materials hide a secret. They keep their real beauty hidden. Only a professional finish can reveal what is inside. sia Abrasives has devoted itself to achieving perfectly finished surfaces for more than 135 years. «Finished by sia Abrasives» – the final touch makes all the difference to a wide variety of materials: Wood acquires its expressive colour, striking colour contrasts or astounding grain, leather captivates with its subtle nuances, contact lenses ensure the very best acuity of vision, metal glows at the peak of its perfection,...

Open the catalog to page 2

Abrasive basics Sanding technology Perfect surfaces sia Abrasives 4–5 Product search – wood-based materials 18 – 19 Product search – solid wood and veneer 24 – 25 Product search – varnish 30 – 31

Open the catalog to page 3

Top-quality products from Switzerland Company The sia Group is based in Frauenfeld, Switzerland, and is one of the world’s top three suppliers of innovative abrasives. It develops, manufactures and markets complete abrasive systems, customised to specific requirements and applications, for the treatment of every type of surface. Sanding has become a surface treatment technology. sia Abrasives employs about 1,250 people worldwide and is represented through local partners in more than 80 countries. Top-quality products from Switzerland The painstaking selection of first-class raw materials,...

Open the catalog to page 4

Environmental-friendly production, competent and ethical waste disposal For many years we have concerned ourselves with the efficient use of energy and committed ourselves to protecting the environment. We have implemented many measures within our production processes to protect the air, land and water. We use our energy and raw-material resources efficiently and carefully. Monitoring raw materials, setting quality standards We manufacture top-quality products by thorough monitoring during the production process. The superior properties of sia products represent excellent value for our...

Open the catalog to page 5

Coated abrasives Non-woven abrasives Foam abrasives

Open the catalog to page 6

Flexible Schleifmittel Classic flexible abrasives and complete finishing systems for conventional surface treatment on all types of material. The basic construction is based on a flexible backing layer. The grit is initially fixed by using a base coat on the flexible backing. The second application of adhesive, the size coat, is made following a drying process and secures the grit more firmly to the backing. Other coatings may be added on top of the size coat. These consist mainly of substances to reduce early choking or clogging of the abrasive during the sanding process or of chemicals...

Open the catalog to page 7

Basic facts Grit minerals The most common materials used to make abrasive grit today are the synthetic minerals aluminium oxide and silicon carbide in their various forms. There is also a growing use of special minerals such as zirconium aluminium oxide, ceramic aluminium oxide and diamond. The use of natural minerals such as garnet and emery, however, is rapidly declining. The grit’s hardness and toughness, which are a function of the starting material used, determine the properties and applications of the abrasives. Hardness (Mohs scale of hardness) White corundum Silicon carbide...

Open the catalog to page 8

Basic facts Due to fluctuations in humidity and / or temperature, i ncorrect storage of abrasives can result in the following negative effects: • changes in dimensions • buckling • reduced sanding performance • belt slippage • belt flutter • breakage of belts or joints Correct storage means: • achieving optimum sanding results • guaranteed product life • guaranteed good performance • saving money Storage conditions: • temperature: 15 – 25 ºC | 59 – 77 ºF • relative humidity 40 – 70% • store abrasives in their original packaging • hang up belts Never store abrasives: • on heaters • near...

Open the catalog to page 9

Basic facts Antistatic finish Without antistatic finish With antistatic finish Static charges Any material-removal process generates friction and static charges, resulting in a positive or negative electrostatic voltage on the workpiece and belt (kV/m). If these charges cannot be conducted to an earth ground, the belt, the workpiece and dust all become statically charged. Antistatic effect However, if sanding belts are used which contain carbon fibres, soot, graphite and / or dissolved salts (electrolytes) in the paper and / or adhesive, static voltages can be grounded through contact...

Open the catalog to page 10

Basic facts TopTec Top technology for perfect surfaces – Controlled scatter Optimum belt joints Dust-free process sia high-tech scatter technology offers the following benefits: sia belt joints offer the following benefits: The antistatic treatment of the belts has the following benefits: • optimum grit volume • perfect grit adhesion • even grit distribution • tested to FEPA standards • high and consistent quality • specific application orientation • high-quality finishing • high level of stability and long service life • no sanding faults ... and, as a result, perfect surface quality...

Open the catalog to page 11

Basic facts Optimum grit sequence Using the optimum grit sequence during the sanding process not only gives better sanding results but is also important in achieving the most e conomical surface treatment. For this reason it is important never to skip more than one grit size at one time! The main exceptions to this are given below: from Contact belt sanding Use next finer grit e.g. P150 and P180 Cross belt sanding Orbital sanding Orbital sanding Hand sanding Skip two grit sizes e.g. P150 and P240

Open the catalog to page 12

Basic facts

Open the catalog to page 13

Sanding technology Wood-based materials Solid wood and veneer Paint

Open the catalog to page 15

Wood-based materials

Open the catalog to page 16

Wood-based materials Plywood (consists mainly of veneers) The term plywood refers to sheets of wood made up of a number of layers of veneer glued one on top of the other. Each layer is rotated through 90° before being glued down to the layer beneath. The grain on the two visible sides runs parallel. The number of layers is therefore uneven. Plywood can be obtained in various kinds of wood and should be finished with an abrasive appropriate to the relevant wood; only the outermost layer is sanded, and this contains no adhesive. Plywood is used mostly for making furniture, models and also for...

Open the catalog to page 17All Sia Abrasives catalogs and technical brochures

-

General Fabrication

48 Pages

-

High-tech belts

24 Pages

-

siaslide Pad S

2 Pages

-

Film sanding belts

4 Pages

-

Coatings and Composites

56 Pages

-

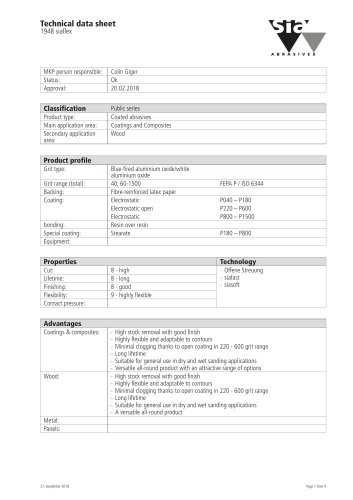

1948 siaflex

4 Pages

-

1931 siawat

3 Pages

-

1944 siaone

3 Pages

-

1913 siawat

4 Pages

-

1713 siawat

3 Pages

-

Metal

40 Pages

-

Automotive

52 Pages

-

sia Abrasives – key series

124 Pages

-

Belt sanding

24 Pages

-

Solid surfaces

16 Pages

-

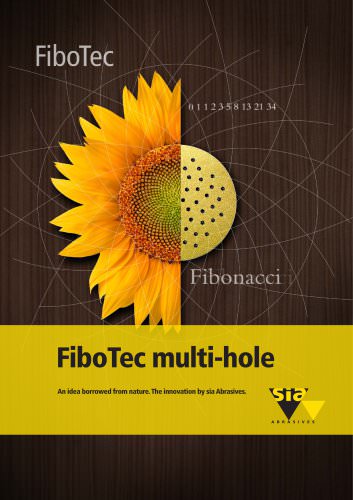

FiboTec Multi-hole pattern

8 Pages

-

Bonded Abrasives

16 Pages

-

microtec - CR-Finishing

16 Pages

-

sia Abrasives Key Series

176 Pages

-

sia Abrasives New Products 2012

72 Pages