Website:

Sesotec GmbH

Website:

Sesotec GmbH

Catalog excerpts

ASM advanced sorting machines Sorting by ■ Color ■ Shape ■ Material type Ensuring maximum product purity, reliability and ease of use

Open the catalog to page 1

Systematic and smart sorting. Professional Solutions for bulk material. pure. With over 30 years of experience in the field of optical sorting technology, Sesotec ASM (Advanced Sorting Machines, a company of Sesotec) is a leading manufacturer of automatic sorting systems for the food industry. ASM has a history of cutting-edge technical development, e.g. as an early-adopter of LED lighting and innovative image reconstruction. Sesotec ASM is Made in Italy. The machine is state-of-the-art with an electronic and software engine designed for optimal performance. The components are built for...

Open the catalog to page 2

ASM QUASAR QUASAR intelligent optical sorter • 4k High-Resolution cameras with True-Color image processing technology. • True-Shape technology to see and differentiate the exact shape of every single kernel, at high speed. • Higher capacity, dedicated optical processor and analysis speed up to 40 kHz. • Sniper ejector logic reduces product loss to a bare minimum. • Even easier to use, with a new HD interface, industrial-grade tablet and auto-calibration. Model Width Height Depth QUASAR 1000 905 mm 1910 mm 1800 mm The ever stringent quality standards are creating new technical...

Open the catalog to page 3

ASM VISION VISION color and material-type sorter • Latest hardware and software. • Highest purity, concentrated rejects. • 0.09 mm camera resolution. • Image reconstruction software. • Optional: Material-type detection with NIR & NIR InGaAs. • LED full-color lighting for a service life of up to 100,000 hours. Model Width Height Depth Weight V100 900 mm 2000 mm 1710 mm 740 kg The ASM VISION Series optical sorter was designed to maximize throughput and defect removal while decreasing false reject. The new software features a user-friendly and intuitive touchscreen. The LED...

Open the catalog to page 4

ASM TIGERBELT TIGERBELT belt-type optical sorter • Belt feeder with variable speed and inclination to ensure optimal product flow. • 4 Full Color RGB-cameras, with 6144 Pixel and an optical resolution 0.09 mm, combined with a data processing speed of 24 Khz, ensure maximum precision and high capacity. • NIR technology detects the presence of foreign material and rotten objects at the same time. • Intuitive user interface with auto-calibration features. • Low maintenance costs and ease of operation. • All our optical sorters have an ethernet connection which allows remote control and...

Open the catalog to page 5

ASM LABSEED LABSEED laboratory color sorter • Suitable dimensions for laboratory and batch operations. • High performance sorting of small batches less than 1 kg. • LED full-color lighting for a service life of up to 60,000 hours. • Very high camera resolution: 0.09 mm. • Auto-learning functionality. Model Width Height Depth Channel width Weight 1000 600 mm 1100 mm 800 mm 90 mm 145 kg ASM LABSEED is the most precise sorter series. It has been designed for quick batch changes in laboratories and research institutes and focuses on sorting accuracy and smaller quantities.

Open the catalog to page 6

Function The product is fed into the sorter through a hopper. A vibration feeder uniformly distributes the material across the operating width and feeds it onto an inclined chute. The correct angle combined with the channel shape and the surface finish allow for an excellent singulation of the product, so that the cameras can inspect the product from both sides. When a passing particle is identified as defective, it is ejected into the reject chute with a precise blast of air from the valve manifold. Good material passes through the sorter untouched. In the sorting process, the contaminated...

Open the catalog to page 7

Sesotec GmbH Regener Straße 130 D-94513 Schönberg Germany Tel. +49 8554 308-0 Fax +49 8554 2606 info@sesotec.com www.sesotec.com Operating Companies: Sesotec Ltd. Hampshire United Kingdom info@sesotec.co.uk www.sesotec.co.uk Sesotec Sàrl Wasselone France info@sesotec.fr www.sesotec.fr Sesotec system world Detecting and separating contaminants: Detecting and separating sub-standard products Removing contaminants: ■ metals ■ plastics ■ glass ■ ceramics, porcelain, stones ■ and many others Qualitative defects: ■ incorrect colour ■ agglomerations ■ breakages ■ air inclusions in packs ■...

Open the catalog to page 8All Sesotec GmbH catalogs and technical brochures

-

RAYCON D+HX Bulk

4 Pages

-

RAYCON D+MX Bulk

4 Pages

-

RAYCON D+HX Dual

4 Pages

-

RAYCON D+HXLW

4 Pages

-

RAYCON D+MXLW

4 Pages

-

RAYCON D+HX

4 Pages

-

RAYCON D+MX

4 Pages

-

RAYCON EX1

4 Pages

-

VARICON COMPACT

2 Pages

-

ELCON

2 Pages

-

Systematic glass recycling

4 Pages

-

VARICON+

2 Pages

-

UNICON+

2 Pages

-

RAPID VARIO-FS

2 Pages

-

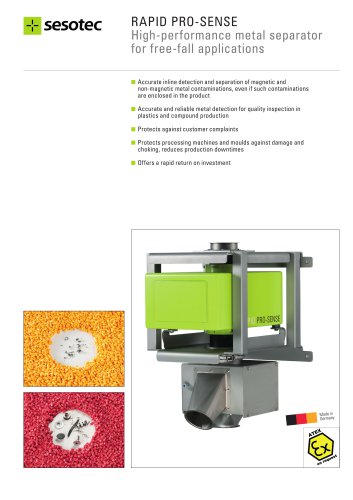

RAPID PRO-SENSE

4 Pages

-

RAPID DUAL

2 Pages

-

RAPID 8000

2 Pages

-

RAPID 6000

2 Pages

-

RAPID 5000

2 Pages

-

RAPID 4000

2 Pages

-

PROTECTOR

2 Pages

-

PROTECTOR-MF

2 Pages

-

SAFEMAG

2 Pages

-

LIQUISCAN VF+

2 Pages

-

PROTECTOR PROFESSIONAL

2 Pages

-

LIQUISCAN PL

2 Pages

-

INTUITY

2 Pages

-

GLS

2 Pages

-

GF

2 Pages

-

GF 4000

2 Pages

-

ELS

2 Pages

-

ASM VISION

4 Pages

-

LIQUIMAG

2 Pages

-

EXTRACTOR-SE

2 Pages

-

MAGBOX-MXP

2 Pages

-

MAGBOX-MXF FOOD/PHARMA

2 Pages

-

FLAKE PURIFIER+

2 Pages

-

K9

2 Pages

-

SPEKTRUM

2 Pages

-

VARISORT

2 Pages

-

VARISORT COMPACT

2 Pages

-

ASM QUASAR

4 Pages

-

Metal & E-Scrap Recycling

4 Pages

-

All about PET.

8 Pages

Archived catalogs

-

RAYCON 130/240

4 Pages

-

MAGBOX FOOD

2 Pages

-

C-SCAN DLS

2 Pages

-

RAPID PRO SENSE

4 Pages

-

RAYCON

6 Pages

-

LIQUIMAG AUTO-CLEAN

2 Pages

-

X-Ray Scanner

6 Pages