Website:

Sesame Motor Corp.

Website:

Sesame Motor Corp.

Catalog excerpts

PLANETARY GEARHEADS SERIES LINEUP Exactitude Helical Series Helical & Spur Series (Helical, Nickel-Plating) Standard Spur Series Primary Spur Series SESAME MOTOR CORP PLANETARY GEARHEADS// (Helical, Nickel-Plating) (Helical, Nickel-Plating) (Helical, Baking-Varnish) Products due to human error, naturai disasters or other factors lead to poor or damaged, will not be covered under warranty.

Open the catalog to page 2

CODING SYSTEM H: Wt&mW&W. Exactitude Helical Series G: ffi^IH Precision Series C: ySMW Primary Series U: fig^S Heavy Duty Series T: ttlifflgy Muti-Shaftea Series P: HHiSiy Light Load Series L: 75ff^^lB@ Sauare Housing with Flange C: W£W£MW Round Housing without Flange E: MTf^flJSfiSiS Round Housing with Flange R: MftM Right Angle F: H^illSS Plate Type Square Flange Helical Gear (Square Flange Helical Gear for G Grade (Precision Series) Only) (Speed Reduction fSBR (Backlash) P0: fflj&Wgk Micro Backlash P2: ffiggtik Standard Backlash W(Customer Specification) (Motor Model) \$&&MWttRa'fife...

Open the catalog to page 3

(^Planetary Gearbox Operation Manual j itT^f^^^ji - SHORTIES*

Open the catalog to page 4

(^Planetary Gearbox Operation Manual j 1.1 Preparation before installation ■ Please read this operation manual before using this motora Any problems caused by inappropriate operation contrary with the manual, or damage caused by natural disasters, or restructure the Motor without our permission, Sesame will not hold any responsibility nor will the Motor be cover by warran- ■ Warranty start within one year after purchase the Motor. Within warranty period, if Motor damage is not cause by operation error nor by natural disaster, then please send back the Motor, we should replace the damage ■...

Open the catalog to page 6

4. MOTOR CONNECTIVETY WITH GEARBOX 4.1 Check the motor and gearbox size. Clean the mounting surface. 4.2 Take off the plug from the adapter plate. Revolve the set collar until the bolt is aligned with the hole. 4.3 Remove the key from the shaft. Mounting the balance key if necessary. 4.4 Make sure the motor shaft size. Choose shaft, be sure to align the collet gap over the flat 4.5 Tighten the mounting in 1-4 order with torque wrench to 5% specified torque. (See P.35-P.42) 4.6 Tighten the set collar bolt with torque wrench to specified torque. 4.7 Tighten the mounting in 1~4 order with...

Open the catalog to page 7

@ PHL ^^ffl^ia(Tightening Torque Table) H (Table 1. Tightening Torque Recommended for Motor Mounting Bolt) Notel: Holding torques must be bigger than values shown aboves. Bolts can be tightened up to 20% hig her for increased holding Note2: Applicable type : PHF - PGF series.

Open the catalog to page 8

PGRH ^ffl;b^(Tightening Torque Table) H (Table 1. Tightening Torque Recommended for Motor Mounting Bolt) Notel: Holding torques must be bigger than values shown aboves. Bolts can be tightened up to 20% hig her for increased holding Note2: Applicable type : PGLH series.

Open the catalog to page 9

•ffl^]^(Tightening Torque Table) I- 1 (Table 1. Tightening Torque Recommended for Motor Mounting Bolt) Notel: Holding torques must be bigger than values shown aboves. Bolts can be tightened up to 20% hig her for increased holding Note2: Applicable type : PGR series.

Open the catalog to page 10

H (Table 1. Tightening Torque Recommended for Motor Mounting Bolt) Notel: Holding torques must be bigger than values shown aboves. Bolts can be tightened up to 20% hig her for increased holding Note2: Applicable type : PGE - PEE series.

Open the catalog to page 11

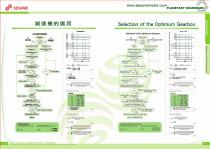

TmB Max. Output Torque of the Motor

Open the catalog to page 12

Special locking mechanisms designed of the output shaft ensure its integration closely with positioning gear, power transmission efficiency, and eternal Planetary arm bracket and output shaft are one-piece constructed, setting bearing apart for larger span to reach the largest reverse rigid and contribute high axis radial load capacity. Grinding process Ra 0.2pm to smooth surface of output shaft, and with oil-seal to minimum friction coefficient and reducing start up load; result in the best seal-ability and extended lifespan. PHL series helical gear design, enhance tooth engagement rate of...

Open the catalog to page 13

PHL Single Stage Dimensions ★ C1 ~C9J14JSflIJ(l)liiilSrffi/?\r,af5Bi^fflKl,lBi*S. ★ C1 ~C9 are motor specitc dimensions(metric std shown ). Size may vary according to the motor flange chosen. ★ *a^*tt-liW±»«8it8Sf7SafteM*Sy7£S]. * Specification subject to change without notice.

Open the catalog to page 14

@^PHL ^mWfegM. Specifications Table Stage Ratio Nominal Output Torque Emergency Stop Torque 3.0 f88H3£Witij73>£ (3.0 times of Nominal Output Torque) ( * EkA.Wiiij73f& Max. Output Torque Tits =60% of Emergency Stop Torque) Nominal Input Speed Torsional Rigidity ffiffliSfS Operating Temp. (SSPSfJ Service Life 20,000(10,000/ SilHSiW Continuous operation) : Protection Class EiStfc Ratio SUSS Stage mfil unit SlK^aEXiKliftJfflBB Synthetic Lubricant LlfittiWiS 100rpm S&f^ffi&ffittjMcWful Applied to the output shaft center @100rpm. 2.3000rpm QKMffl Measured at 3000rpm with no load...

Open the catalog to page 15

PHF^IJ HftJ Planetary arm bracket and output shaft are one-piece constructed, using tapered roller bearings can bear the axial load and radial load that are more than deep groove ball bearings. Setting the bearing apart for larger span to reach the largest torsional rigidity and contribute high axial load and radial load capacity. Alloy steel gear with unique vacuum carburizing and heat treatment for the best surface hardness and inner core tenacity. Additionally, with gear grinding process-ing to get the best accuracy, high wear resistance and high wear resistance and high impact...

Open the catalog to page 16

@ PHFWKflSiR^H PHF Single Stage Dimensions Products due to human error, natural disasters or other factors lead to poor or d

Open the catalog to page 17

PGH Single Stage Dimensions ★ C1~C9Sfi««aM«»ffit£R^,affiffiSfflftBil>*£. ★ C1-C9 are motor specitc dimensions(metric std shown ), Size may vary according to the motor flange chosen. ★ *'£3]mm$tmiiL±Mamt§m?il&BtSW*9ifi%m. ★ Specification subject to change without notice.

Open the catalog to page 18

^PGH 'f4ib^t§^^ Specifications Table Products due to human error, natural disasters or other factors lead to poor or damaged, will not be covered under warranty. Products due lo human error, natural disasters or other (actors lead to poor o*" damaged, will not be covered under warranty

Open the catalog to page 19All Sesame Motor Corp. catalogs and technical brochures

-

InLINE (OUTPUT SHAFT) SERIES

86 Pages

-

Right Angle Series

35 Pages

-

SERVO MOTOR GEARHEAD ENG

162 Pages

-

PEC

12 Pages

-

SGC series

10 Pages

-

PUR series

6 Pages

-

PHF series

9 Pages

-

CLUTCH BRAKE MOTOR

2 Pages

-

ELECTRONIC INSTANT BRAKE

2 Pages

-

Magnetic Brake Motor

4 Pages

-

TORQUE MOTOR

1 Pages

-

LINEAR ACTUATOR

1 Pages

-

PLANETARY GEARHEADS

162 Pages

-

GB Series Speed Reducer

2 Pages

-

MOTOR AND SPEED REDUCER

70 Pages

-

Customization Products

2 Pages

-

Precision Gear Motor Catalog

23 Pages

-

Motor and Reducer Catalog

30 Pages