Website:

HENNIG FRANCE

Website:

HENNIG FRANCE

Group: Hennig

Catalog excerpts

global excellence in machine protection PRODUCT RANGE » {HSq /Telescof»c Steel Covers » Folded Bellows ■ XYZ Modules/ Flex Protect Systems ► Flexible Apron Covers » Wiper Systems » Stabiflex Cable Conduits ■ Stabilastic Telescopic Springs 9 Chip Conveyors/ Filtration Systems » Power Generator Enclosures perfect machine piolection NORTH AMERICA HEADQUARTER » EUROPEAN HEADQUARTER Hen rug GmbH, Kirchheim (Germany). with agencies for all German states Czech Republic Creat Bntain South Korea SALES PARTNER BeNeLux Countries/Denmark Czech Republic/Eastern Europe South Africa • SERVICE STATIONS Czech Republic Ovary Mexico City

Open the catalog to page 1

HENNIG ORGANISATION GOELLNER INC. USA Competence Center Conveyors ADVANCED MACHINE & ENGINEERING CO. USA HENNIG HOLDING GMBH GERMANY Competence Center Conveyors HENNIG GMBH GERMANY licensee / partner Competence Center Conveyors COBSEN LTDA. BRAZIL Competence Center Conveyors ENOMOTO INDUSTRY CO. LTD JAPAN OSUNG MECHATRONICS CO. LTD KOREA

Open the catalog to page 2

SERMETO •Location Creuzier le Neuf, France With more than 30 years of experience in the design and manufacturing of chip conveyors, we offer customized solutions for all requirements

Open the catalog to page 3

Our Products: Chip Conveyors and filtration systems CHIP CONVEYORS 5000 LITERS FILTRATION TANK WITH HYDROSTATIC FILTER AND DRUM FILTER FILTRATION TANK WITH HYDROSTATIC FILTER CHIP BREAKER WITH PUMP BRINKMANN

Open the catalog to page 4

Customized solutions for all requirements Hinged steel belt conveyors Type S Only one and same caisson allowing the assembly of an hingedsteel belt for long chips or a drag-link belt for short and broken chips according to the working needs of the machine. Change-kit (hingedsteel belt or drag-link belt) at disposal for the interchangeability of the conveyor

Open the catalog to page 5

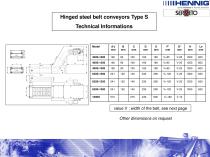

Hinged steel belt conveyors Type S Technical Informations value V : width of the belt, see next page Other dimensions on request

Open the catalog to page 6

Hinged steel belt conveyors Type S Technical Informations Standard width SERMETO V mm Other dimensions on request

Open the catalog to page 7

Options : Cabinet head design for an aesthetic integration with machine shape - Brush system for optimisation of discharge for fine chips, - Comb system for optimisation of discharge for long chips, - Kit multi-function : brush and comb - Possibility EN 618 compliance flange for long conveyors Flat band for reduced space Tank with filtration baskets / pumps …. Stabilising foot Standards gearmotors SEW or Bonfiglioli. Other on request

Open the catalog to page 8

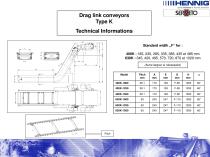

Drag link conveyors Type K Lower dragging: Standard width SERMETO V mm Other dimensions on request Top dragging is used in case of long chips to avoid that these ones surround themselves around upper and lower drag bars, or possibly in case of small parts.

Open the catalog to page 9

Drag link conveyors Type K Technical Informations Standard width „F“ for : 400K : 185, 235, 285, 335, 385, 435 et 485 mm 630K : 345, 420, 495, 570, 720, 870 et 1020 mm (Autre largeur si nécessaire) Model

Open the catalog to page 10

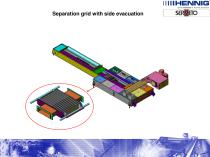

Non standard painting (RAL to be specified) Junction box Cabinet head design for an aesthetic integration with machine shape Mist / Smoke exhaustion with lateral channel flange for long conveyors Wearing sheet, High durability (E36, Creusabro, …) Separation grid with side evacuation Stabilising foot Tank with filtration baskets / pumps …. Standards gearmotors SEW or Bonfiglioli. Other on request

Open the catalog to page 11

global excellence in machine protection

Open the catalog to page 12

Driving system The driving system consists of a gear mzdotor assembled on a driving shaft and of a torque arm for its stop in rotation. Used gear motor is of the type wheel and worm, or conical couple ( better output). Bearing Driving shaft Gear motor When the required couple becomes too important, the torque arm compresses the spring until it starts the electrical contactor which will provoke the stop of the gear motor power supply .

Open the catalog to page 13

Driving system Electrical contactor Adjusting crew Spring Compression value Compression nut

Open the catalog to page 14

Tank with filtration baskets Tanks can be delivered with filtration system. « Filtration tanks » can be delivered with filtration baskets, high pressure or low pressure pumps for the return of the clean liquid towards the machine and also with cleaning pumps. These filtration systems allow a filtration of the cutting liquid up to 560 microns for the tanks with baskets and up to 10 microns for the special filtration systems Filtration tank example Conveyor with filtration tank

Open the catalog to page 15

global excellence in machine protection

Open the catalog to page 16

Magnetic conveyor Type M For split steel chips compatible with the magnetic action. This technology allows the conveying of steel broken chips and small steel parts. Stainless steel caisson Type Standard width SERMETO F mm 209 Other dimensions on request

Open the catalog to page 17

Customized solutions for all requirements Harpoon conveyor Conveyor for scrap metal Screw conveyor Centralized swarf treatment with distribution of chips thanks to a rotating chute

Open the catalog to page 18

global excellence in machine protection

Open the catalog to page 19

Chip disk filtration (Hennig patent) Handles unique and multiple machine configurations • System solution with wide application versatility • Efficient two stage filtration with optional third stage • Filters both water soluble and oil coolants • Flow rates of 1100 gpm plus • Suitable for virtually all material types • Hinge belt and scraper configurations available • Low profile for lathe applications

Open the catalog to page 20

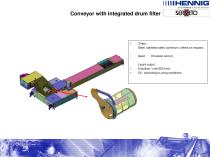

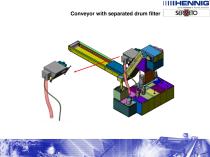

Conveyor with integrated drum filter Chips : Steel, stainless steel, aluminum, others on request.. Liquid output : Emulsion : until 500 l/min. Oil : according to using conditions.

Open the catalog to page 21

global excellence in machine protection

Open the catalog to page 22

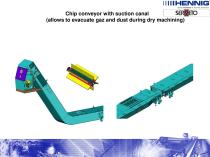

Chip conveyor with suction canal (allows to evacuate gaz and dust during dry machining)

Open the catalog to page 23

Tightness with the machine Examples of tightness with the machine in the loading Telescopic chute, allowing the chip guide and tightness with the conveyor. Watertight flange connection Sealing formed with a neoprene gasket compressed Tightness on the contour of the chute using a gasket

Open the catalog to page 24

Examples of compliance with EN 618 Chute of height 550 mm located at 1100 mm from the ground preventing the user to access the part of the unloading part of the conveyor System of intrusion detection of the object in the unloading part of the conveyor

Open the catalog to page 25All HENNIG FRANCE catalogs and technical brochures

-

CONVEYORS & FILTRATION

28 Pages

-

MACHINE PROTECTION

84 Pages

-

ROLL-UP COVERS

1 Pages

-

APRON COVERS

1 Pages

-

CHIP CONVEYORS

15 Pages

-

WIPER SYSTEMS

20 Pages

-

Brochure Sermeto

5 Pages