Website:

SCHENCK RoTec GmbH

Website:

SCHENCK RoTec GmbH

Group: Dürr

Catalog excerpts

DH 2 - DH 13 High Speed Balancing and Ovespeed Test Facility For more than 40 years Schenck RoTec has been engaged in the development and design of special high-speed balancing machines for heavy turbine and generator rotors as well as for high-speed compressors of steam and gas turbines. Constant exchange of experience between Schenck RoTec and renowned manufacturers of electrical and turbo machinery have lead to the development of the special DH bearing pedestals for balancing machines. These are equipped with isotropically supported bearings, providing equal stiffness in all bearing plane radial directions, and are suitable for use at extremely high balancing and test speeds. DH bearing pedestals are designed for the following applications: • Low speed balancing • Checking of rotor balance at high speeds (operational speed) Balancing and overspeed testing under vacuum Due to the high windage effect of bladed rotors at high speeds and the associated power and temperature problems, balancing and overspeed testing takes place under vacuum conditions with a residual pressure of approx. 0.5 - 2 mbar. Explosion proof enclosure • Dynamic straightening of flexible rotors • Testing of material strength by operating rotors at overspeed • Rotor investigation in operational bearings. All these tasks can be performed in a single rotor set up. The most important features of these high-speed balancing systems are shown on the next page. Rigid bearing supports – Additional stiffness Rigid bearing supports provide for greater stability, particularly at high speeds. A supplementary, remote controlled change-over facility enables the stiffness of the bearing pedestals to be varied, thus enabling rotor resonance frequencies to be passed through safely, and minimizing the risk of damaging the rotor or the balancing facility. To protect the surroundings from the dangers resulting from a total or partial explosion of the rotor, a variety of different solutions can be recommended: Longstanding experience has shown that a walk-in tunnel design is most suitable, especially for medium or large facilitiesFor rotors weighing up to 8 t, with outer diameters up to 1.7 m, an axially sliding vacuum chamber with integrated burst protection can be used. The movable part of the chamber is equipped with several steel liners, which act as burst protection. If the specimen bursts, the burst energy is absorbed by deformation elements in the foundation. A compact design enables the facility to be installed on the shop floor. Drive system For high-speed balancing, overspeed testing and dynamic straightening of flexible rotors, either a three-phase servo motor with frequency converter or an infinitely variable DC motor with thyristor control can be used . Schenck RoTec GmbH Landwehrstrasse 55 D-64293 Darmstadt Telefon (0 61 51) 32 23 11 Telefax (0 61 51) 32 23 15 http://www.schenck-rotec.de E-Mail rotec@schenck.net

Open the catalog to page 1

DH 2 - DH 13 High Speed Balancing and Ovespeed Test Facility Depending on the required speed range, a suitable transmission gear has to be installed. A so-called intermediate shaft constitutes the connection between the gear and the over-speed testing chamber. Rotors are coupled to this intermediate shaft by means of precision drive shafts. Oil supply, vacuum and monitoring systems To operate a high-speed balancing facility, a number of auxiliary systems are required, such as: • Oil supply systems for oil supply to the rotor bearings, the turbo gear and the intermediate shaft of the drive...

Open the catalog to page 2

DH 2 - DH 13 High Speed Balancing and Ovespeed Test Facility For better utilization of overspeed test facilities, several bearing pedestal sizes may be used in one facility. Here, a compressor is shown being balanced in an overspeed test facility size DH 4, using DH 2 bearing pedestals, at test speeds up to 50000 min-1. Mounting of a large generator on DH bearing pedestals 1 Electric drive2 Gearbox3 Intermediate shaft4 Vacuum tunnel5 Oil station for vacuum operation6 Pump station for lubricating oil7 Vacuum pump station8 Oil station for atmospheric operation9 Emergency oil tank (approx. 10...

Open the catalog to page 3

[min-1] 1,500 to 63,000 depending on drive 1,500 to 63,000 depending on drive 1,500 to 63,000 depending on drive 1,500 to 63,000 depending on drive Drive power Technical data at a glance [kW] 55 to 8,000 depending on drive 55 to 8,000 depending on drive 55 to 8,000 depending on drive 55 to 8,000 depending on drive [min-1] 1,500 to 63,000 depending on drive 1,500 to 63,000 depending on drive 1,500 to 63,000 depending on drive 1,500 to 63,000 depending on drive Drive power [kW] 55 to 8,000 depending on drive 55 to 8,000 depending on drive 55 to 8,000 depending on drive 55 to 8,000 depending...

Open the catalog to page 4All SCHENCK RoTec GmbH catalogs and technical brochures

-

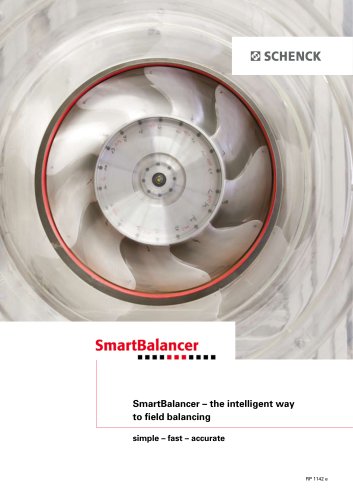

SmartBalancer

8 Pages

-

HS 10 - 40, HS 10 Twin

3 Pages

-

VIRIO

6 Pages