Website:

Schenck Process Holding GmbH

Website:

Schenck Process Holding GmbH

Catalog excerpts

schenckprocess group Container Loading Systems High Speed Bulk Product Loading for ISO Containers we make processes work

Open the catalog to page 1

Introduction Members of the Schenck Process Group, Stock Redler Ltd are leading providers of feeding, automation and bulk solids handling solutions. The Schenck Process Group are global market leaders for solutions in measuring and process technologies in industrial weighing, feeding, screening and automation. Always close to the customer, with an unrivalled global network of operating companies we are your competent global partner for weighing, feeding, screening and automation solutions throughout the process industries. Our philosophy is based on... Continuous product development Best...

Open the catalog to page 2

FulFiller Container Loading made simple... Belt Thrower Principle The FulFiller uses a throwing belt which is supported on two rollers and rotates at high speed. The material being loaded falls onto the belt, is accelerated through 90° and thrown from the loader into the container. The throwing action minimises material degradation and is therefore ideal for all pellets and granules. The key dimensions shown are required to ensure the FulFiller operates efficiently. The height above the inlet is needed to ensure the quoted loading rates are achieved – the FulFiller will operate with lower...

Open the catalog to page 3

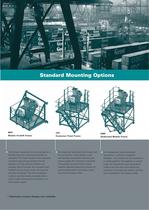

Standard Mounting Options MFF Mobile Forklift Frame The thrower assembly can be mounted on a Forklift Frame for maximum flexibility in operation. The frame locates to the standard container lugs and guarantees that the thrower is in the optimum position for loading. Once mounted, the container and FulFiller can be driven under the required silo and connected. The unit is supplied ready to use and comes complete with a power cable and plug for connection to a local power supply. * Alternative custom designs also available CFF Customer Fixed Frame For single silo operations, the thrower can...

Open the catalog to page 4

FloMaster Circular Bin Discharger Fitted beneath circular silos or bins for the positive discharge of difficult materials No bridging or blockage at the silo outlet Compact construction Versatile in material control Single, Two or Three Stage units Totally enclosed Safe/good access for maintenance Modular Configuration To exactly match your requirements, the FulFiller can be configured using individual components: Thrower The basic thrower is ATEX certified for Zone 22 use and is supplied with a fixed speed drive suitable for either 50 or 60Hz 3 phase power supplies. Variable speed drives...

Open the catalog to page 5

schenckprocess group Stock Redler Limited Redler House Dudbridge, Stroud Schenck Process GmbH we make processes work

Open the catalog to page 6All Schenck Process Holding GmbH catalogs and technical brochures

-

Smart Dust Collection Solution

12 Pages

-

Precise feeding solutions

4 Pages

-

FulFiller ®

8 Pages

-

MULTIBELT® Belt Weigher

8 Pages

-

CONiQ® Cloud

1 Pages

-

MULTIRAIL® BogieLoad pro

20 Pages

-

MaxiStore®

8 Pages

-

Pharmaceutical industry

10 Pages

-

MULTIRAIL®

16 Pages

-

Company overview

20 Pages

-

Your way to Schenck Process

4 Pages

-

We make processes work

20 Pages

-

Material Handling Solutions

8 Pages

-

Capabilities of Stock

8 Pages

-

LinaClass® screens

6 Pages

-

Screenex® screening media

24 Pages

-

CONiQ®

12 Pages

-

Enduro isolation springs

4 Pages

-

MCPP

12 Pages

-

ModuPlasma

8 Pages

-

Airlocks and Diverter Valves

6 Pages

-

MaxiStore®

8 Pages

-

SacMaster®

8 Pages

-

Screen Rebuild Program

4 Pages

-

Food industry

20 Pages

-

MultiTrain® Technology

4 Pages

-

Training that delivers!

38 Pages

-

Cement industry

16 Pages

-

MoveMaster® chain conveyors

8 Pages

-

TEDO Conveyors

18 Pages

-

ProPulse Industrial Air Filters

12 Pages

-

Drop forged chain

8 Pages

-

RoCon® Series 6

8 Pages

-

Sustainable Cement Production

10 Pages

-

Under the harshest conditions

16 Pages

-

SPro screen panels

12 Pages

-

LOGiQ® loading automation

10 Pages

-

Power industries

16 Pages

-

Tidal Series 5

6 Pages

-

Screen rebuilding

4 Pages

-

RotoScrew

2 Pages

-

Rotofeed Pneumatic Injector

2 Pages

-

DWB

4 Pages

-

MultiFlex

4 Pages

-

Stock Forry® ESP Products

8 Pages

-

LinaClass®

6 Pages

-

Air pollution control

4 Pages

-

Stock Valves

8 Pages

-

Product Overview

8 Pages

-

MULTIDOS® H - Weighfeeder

2 Pages

-

MULTIDOS® E - Weighfeeder

4 Pages

-

SacMaster

1 Pages

-

MULTIBELT®

1 Pages

-

MULTIDOS® VDP

1 Pages

-

Components and Standard Products

206 Pages

-

DISOCONT ®

4 Pages

-

INTECONT® PLUS

4 Pages

Archived catalogs

-

We make processes work

16 Pages

-

RoCon® Series 6

8 Pages

-

MULTIRAIL® WheelLoad

2 Pages

-

MULTIRAIL® WheelScan

2 Pages

-

MULTIRAIL® MultiBridge

2 Pages

-

MULTIRAIL® LiquidWeight

2 Pages

-

MULTIRAIL® LegalWeight

2 Pages

-

MULTIDOS® L

4 Pages

-

MULTIGRAV®

4 Pages

-

ProFlex® C

2 Pages

-

Mobile Touch Panel FSB

2 Pages

-

DISOMAT® Satus

4 Pages

-

DISOMAT® B plus Ex, Zone 1

4 Pages

-

INTECONT® Opus

4 Pages

-

weighing sensor

1 Pages

-

Rotary Force Exciters

4 Pages

-

Force exciters

4 Pages

-

MULTISTREAM® B

4 Pages

-

MULTICOR® R 450

4 Pages

-

MULTIDOS® E

4 Pages

-

MULTIDOS® M

4 Pages

-

Award Winning Solutions

6 Pages