Website:

Saint-Gobain Performance Plastics

Website:

Saint-Gobain Performance Plastics

Group: Saint-Gobain

Catalog excerpts

SEALING & POLYMER PRODUCT CATALOG PTFE ROTARY SHAFT SEALS

Open the catalog to page 1

Welcome to the Saint- Gobain Seals World: Ex per ience You Can Rely O n. . . Time Af ter Time Saint-Gobain has a rich tradition of excellence that dates back over 345 years. Today, it is one of the world’s top 100 industrial corporations and a leader in the development and production of engineered components and materials. In 1665 Louis XIV signed the letters patent, leading to the creation of the Saint-Gobain Group on an industrial basis. One of the earlier and more notable projects was manufacturing the 357 mirrors for the Hall of Mirrors in the Palace of Versailles. From these...

Open the catalog to page 2

A Tour of O ur Capabi lit ies Saint-Gobain Seals Group’s global presence allows us to manufacture OmniLip™ and DynaLip® throughout the world, with sites located in Garden Grove, California, USA; Kontich, Belgium; Kolo, Poland; Minhang, Shanghai, China; and Suwa, Japan. The majority of our orders are customdesigned through careful and detailed collaboration with each customer, giving them access to the market-leading engineering, research and customer service expertise of our organization. We also understand that there are times when simplicity is the best solution and offer standard...

Open the catalog to page 3

Introduction to OmniLip™ and DynaLip® 5 OmniLip™ Seals: A Closer Look 6 DynaLip® Seals: A Closer Look 7 Aerospace Case Studies 9 Industrial Case Studies 11 Life Science Market 12 Life Science Case Studies 13 Automotive Case Studies 15 Material Charts: A Quick Reference Guide 17 OmniLip™ Standard Seal Types 18 DynaLip® Standard Seal Types 19 Dash Number Size Charts 20 Hardware Variations and Non-Standard Lip Seal Configurations 26 Application Data Form 28

Open the catalog to page 4

W hen O ur Lip Seals Jour ney Began Innovation Is Our Business OmniLip™ was introduced in the early 1970’s and DynaLip® was created in the late 1980’s. The seals were designed to bridge the gap between conventional elastomer lip seals and mechanical face seals. The ability to perform in hostile environments such as extreme temperatures, aggressive media, high surface speeds, high pressure and lack of lubrication are important features of Saint-Gobain Seals Group’s PTFE lip seals. They provide the designer with a signicant improvement in performance over elastomer lip seals while delivering...

Open the catalog to page 5

A C loser L ook at O ur Me tal- Cased Lip Seals Saint-Gobain Seals Group offers a complete line of OmniLip™ metal-cased lip seals, which can be manufactured from a variety of materials for PTFE and PTFE-blended sealing elements. OmniLip™ seals withstand hostile environments and other demanding conditions. They exceed the performance of elastomer lip seals in the following areas: Features/Benefits › Excellent chemical resistance › Low friction (leads to long life) › Capable of surface speeds in excess of 7,000 ft./min. (35 m/s) › Capable of handling wide temperature ranges: -65°F to 450°F...

Open the catalog to page 6

Our DynaLip® seals offer similar performance to our OmniLip™ seals in that they possess excellent chemical resistance and handle high pressure and temperatures. Based on our experience through the years, we have been able to assist our customers in determining when a DynaLip® seal would be more effective than an OmniLip™ seal. The soft surface of the seal’s outer diameter prevents damage of the housing and allows the seal to be easily installed and removed. These seals are used most often in applications that require seal removal in order to be changed or cleaned such as in medical or...

Open the catalog to page 7

AEROSPACE MARKET W here O ur Lip Seals Achieve the Greatest Heights At Saint-Gobain Seals Group, quality and innovation are of the utmost importance. We have extensive experience in meeting sealing requirements for various aerospace applications. We have seals in commercial, military, xed wing and rotary wing aircrafts, as well as spacecraft. Our design engineering team and technical staff provide customized solutions that meet your needs. This process includes developing a prototype, testing the solution, manufacturing the part to specications and delivering it on time. Our product quality...

Open the catalog to page 8

Case St udies OMNILIP™ AEROSPACE Application: Turbine Engine Aircraft Accessory Gearbox Product: Typical Shaft Speed: Typical Shaft Size Range: Typical Surface Velocity: Typical Pressure: Typical Temperature: Turbine Oils, all types Improves performance over elastomer seals Reduces leakage Provided with installation tool and extraction feature Available with elastomeric seal case coating to prevent damage to the mating housing bore • Requires less space than mechanical carbon face seal Application: Flap Actuator Product: Typical Shaft Speed: Typical Shaft Size Range: Typical Surface...

Open the catalog to page 9

INDUSTRIAL MARKET Saint-Gobain Seals Group designs rotary shaft seal solutions for many demanding applications within the industrial and manufacturing markets. In most cases, this requires lip seals capable of enduring extreme speeds, pressures and temperatures. Our innovative designs, combined with high-quality lip materials and product capabilities at extreme conditions, make us the right partner to help you meet your dynamic sealing requirements. Features/Benefits › Excellent chemical resistance › Can endure abrasive media › Can perform with poor/limited lubrication › Custom designs...

Open the catalog to page 10

Case St udies OMNILIP™ INDUSTRIAL Application: Freon Recovery Pump Product: Typical Shaft Speed: Typical Shaft Size Range: Typical Surface Velocity: Typical Pressure: Typical Temperature: Meets strict EPA leakage requirements Seals will last life of the pump Accommodates small space for seal Ease of installation Compatible with a wide range of oils and refrigerants Application: Screw Compressor Product: Typical Shaft Speed: Typical Shaft Size Range: Typical Surface Velocity: Typical Pressure: Typical Temperature: Seal life in excess of 15,000 hours Reduces warranty claims Tight leakage...

Open the catalog to page 11All Saint-Gobain Performance Plastics catalogs and technical brochures

-

saint-gobain seals

6 Pages

-

automotive industry

6 Pages

-

aerospace industry

6 Pages

-

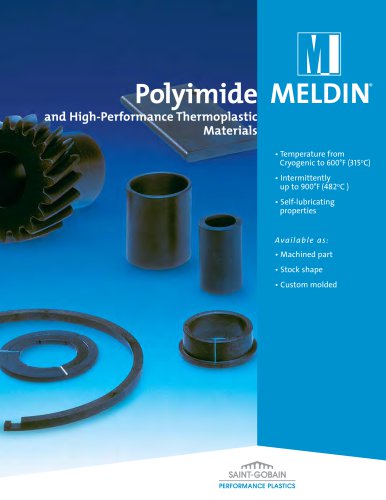

Meldin® Thermoset

12 Pages

-

Meldin® Thermoplastic

44 Pages

-

Rulon® Fluoropolymer

28 Pages

-

OmniSeal® Spring-Energized Seals

60 Pages

-

OmniSeal® Rotary Lip Seals (US)

34 Pages

-

Omniflex Fluoroelastomer seals

20 Pages

-

OmniSeal® Backup Rings

1 Pages

-

Meldin® 7000 Series Design

17 Pages

-

Fluoroloy® A08

1 Pages

-

Fluoroloy® A01

1 Pages

-

OmniSeal® Spring Energized Seals

32 Pages

Archived catalogs

-

Meldin® CMP Retaining Rings

4 Pages

-

OmniLip, PTFE Rotary Lipseals

16 Pages

-

OmniSeal, Spring Energised Seals

32 Pages