Website:

Sacmi Labelling

Website:

Sacmi Labelling

Group: sacmi

Catalog excerpts

ROLL-FED Labelling Machine

Open the catalog to page 1

Opera is born to satisfy the growing demand for a simple, safe and reliable roll-fed labelling machine. Opera is Sacmi ideal solution for those bottlers who want to exploit the great advantages of the roll-fed labelling by using innovative and suitable materials for their image and tradition. Making the machine operate apart from the variations of the hot melt glue or the label materials features is the basic idea of Opera project. Opera roll-fed machinery range is suitable to work cylindrical or shaped containers made of plastic, glass or metal,(full or empty) with wrap-around labels....

Open the catalog to page 2

Machine standard features Caratteristiche standard della macchina Caractéristiques de série de la machine Características estándar de la máquina Roll-fed labelling station The roll-fed labelling station is driven by its own servomotor, independent from the machine. It is equipped with two independent reel stands, complete with film tension control device.During its unwinding, the film is controlled by a continuous, automatic correcting system of its vertical position [web tracker]. The film feeding roller is controlled by a servo-motor which adjusts the film feeding speed in accordance with...

Open the catalog to page 4

Autosplicing System Labelling group

Open the catalog to page 5

DISCHARGE LABELLING MACHINE STANDARD FEATURES

Open the catalog to page 6

INFEED LABELLING AGGREGATE HYDRAULIC PNEUMATIC PANEL ELECTRICAL CABINET PANEL VIEW

Open the catalog to page 7

Groupe d’étiquetage à bobine continue (roll-fed) Le groupe d’étiquetage à bobine continue (roll-fed) est propulsé par un moteur brushless indépendant de la machine. Il est équipé de deux supports bobine (reel stand) indépendants, complets de dispositif de contrôle de la tension de la bande support. La bande support est contrôlée, pendant son déroulement, par un système de correction automatique et continue de la position vertical de la bande même (web tracker). Le rouleau de traction (feeding roller) de la bande support est contrôlé par un moteur brushless qui corrige la vitesse...

Open the catalog to page 8

Labelling group Reel Support Cutting System

Open the catalog to page 9

Main carousel The machine main carousel height is electrically adjustable by means of a device placed on the control panel. The platforms are of the self-centring type and their support surface is covered by anti-slipping material to ameliorate the container holding. The main carousel peripheral ring is made of aluminium. The platforms rotation is transmitted - in accordance with the containers type (cylindrical or shaped) - by a toothed belt (R version) or a mechanical cam (SR version). Base frame and main structure Anti-vibration and noise-absorption strong structure. The upper surface is...

Open the catalog to page 10

Carosello principale L’altezza della testata della macchina viene regolata elettricamente mediante un comando da pannello operatore. I piattelli portacontenitori sono di tipo autocentrante e la superficie d’appoggio è ricoperta di materiale anti-slittamento per migliorare il bloccaggio del contenitore. L’anello periferico della giostra principale è in alluminio. La rotazione dei piattelli viene trasmessa a seconda della tipologia dei contenitori (cilindrici o sagomati) con cinghia dentata (versione R) o con camma meccanica (versione SR). Basamento e struttura principale Robusta struttura di...

Open the catalog to page 11

Carrousel principal La hauteur du carrousel central de la machine est réglée électriquement par un dispositif placé sur le pupitre opérateur. Les plateaux porte-conteneurs sont à centrage automatique et leur surface d’appui est recouverte de matériel anti-glissement pour améliorer le blocage des conteneurs. L’anneau périphérique du carrousel central est en acier inox. La rotation des plateaux porte-conteneurs est transmise par courroie dentée et poulies si on traite des conteneurs cylindriques (version R) ou par came mécanique si on traite des conteneurs de forme (version SR). Bâti et...

Open the catalog to page 14

ES Carrusel principal La altura del cabezal de la máquina es regulada eléctricamente por medio de un comando en el panel del operador. Los platillos porta-recipientes son de tipo auto centrado y la superficie de apoyo está cubierta con materiales anti-deslizamiento con el objeto de mejorar el bloqueo del recipiente. El anillo periférico del carrusel principal es de aluminio.La rotación de los platillos se transmite según la tipología de los recipientes (cilíndricos o perfilados) con correa dentada (versión R) o con leva mecánica (versión SR). Bancada y estructura general Robusta estructura...

Open the catalog to page 15

CUTTING DRUM WEB TRACKER REEL STAND

Open the catalog to page 16

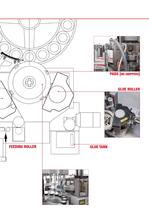

VACUUM DRUM FEEDING ROLLER GLUE TANK GLUE ROLLER PADS [NO GRIPPERS]

Open the catalog to page 17

Sacmi progetta, produce e fornisce una nuova generazione di etichettatrici automatiche rotative per i settori del beverage, food, detergenti, farmaceutica e packaging. Nasce nel 2000 e rappresenta oggi uno dei riferimenti principali nello sviluppo delle nuove tecnologie di etichettaggio. Numerosi sono i fattori che hanno contribuito alla sua crescita costante e alla sua affermazione nel mercato internazionale: primo fra tutti il forte investimento nello sviluppo e nella produzioni di macchinari tecnologicamente avanzati e di grande qualità, per rispondere alle esigenze di ogni cliente....

Open the catalog to page 18

La Société Sacmi Labelling conçoit, fabrique et fourni une nouvelle génération d’étiqueteuses automatiques rotatives pour les secteurs du beverage, food, détergents, pharmaceutique et du packaging. Elle naît en 2000 et représente aujourd’hui un des modèles principaux pour le développement de nouvelles technologies d’étiquetage. De nombreux facteurs ont contribué à son accroissement constant ainsi qu’à son affirmation sur le marché international: le premier est celui de l’investissement considérable concernant le développement et la production de machines technologiquement avancées et de...

Open the catalog to page 19All Sacmi Labelling catalogs and technical brochures

-

KUBE SOLUTIONS

12 Pages

-

SACMI LABELLING SOLUTIONS

44 Pages

-

OPERA COMBI

9 Pages

-

HOT MELT MACHINE

2 Pages

-

OPERA COLD GLUE

2 Pages

-

OPERA PRESSURE SENSITIVE

16 Pages

-

FORMSLEEVE+

9 Pages

-

Pressure Sensitive labellers

8 Pages