Website:

S. A. Armstrong Limited

Website:

S. A. Armstrong Limited

Catalog excerpts

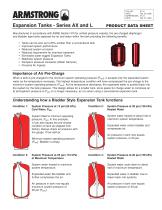

FILE NO: DATE: SUPERSEDES: DATE: Expansion Tanks - Series AX and L PRODUCT DATA SHEET Manufactured in accordance with ASME Section VIII for unfired pressure vessels, the pre-charged diaphragm and bladder type tanks separate the air and water within the tank providing the following benefits. Tanks can be size up to 80% smaller than a conventional tank Improved system performance Reduced system corrosion Reduced requirement for chemical treatment Eliminates water-logged Expansion Tanks Stabilizes system pressure Dampens pressure transients (Water Hammer) Prevents Air Ingress Importance of Air Pre-Charge When a tank is pre-charged to the minimum system operating pressure (PMIN), it accepts only the expanded system water as the temperature increases. The highest temperature condition will have compressed the pre-charge to the maximum system operating pressure (PMAX). As the temperature decreases, the expanded water is pushed back into the system by the tank pressure. This design allows for a smaller tank, since space for charge water to compress air at atmospheric pressure to PMIN is no longer necessary, as it is when using a conventional expansion tank. Understanding how a Bladder Style Expansion Tank functions Condition 1: System Pressure at 12 psi (83 kPa) Cold Water, PMIN System water heated to about half of maximum system temperature. System filled to minimum operating pressure, PMIN. In this example, 12 psi also equals the pre-charge condition of tank as shipped from factory. Always check air pressure with tire gauge. If low add air. Expanded water enters bladder and compresses air. Air pressure in tank now equals system pressure, or 20 psi. Minimum system operating pressure (PMIN). Bladder is empty. System Pressure at 25 psi (172 kPa) at Maximum Temperature System Pressure at 20 psi (138 kPa) Heated Water System Pressure at 20 psi (138 kPa) Heated Water System water heated to maximum system temperature. System water cools down to about half of maximum temperature. Expanded water fills bladder and further compresses the air. Expanded water in bladder now is drawn back into systems. Air pressure in tank now equals maximum system pressure of 25 psi (PMAX). Air pressure in tank now equals system pressure of 20 psi.

Open the catalog to page 1

Determining Total System Volume Add the total pipe water volume in gallons (from Tables) to the total water volume of all system components in gallons. Boilers, Heat Exchangers, etc.: Pipe Volume in Gallons per Foot Pipe Diameter Steel Pipe (Sch. 40) Copper Tube 18 Copper Tube 20 Water Content in Heat Exchangers 1½" Shell Diameter Pipe Diameter Steel Pipe (Sch. 40) Copper Tube Cold Water Supply Relief Valve Pressure Reducing Valve Armstrong Circuit Balancing Valve Armstrong Vortex Air Separator Return From System Gallons per Foot for Shell Length Armstrong Vertical In-Line Pump Expansion...

Open the catalog to page 2All S. A. Armstrong Limited catalogs and technical brochures

-

Intelligent Variable Speed

20 Pages

-

NEW FULL-LINE BROCHURE

40 Pages

-

Vertical In-Line Fire Pump

4 Pages

-

E.2 Series

4 Pages

-

Double Wall Shell & Tube

2 Pages

-

hydroPAK Product

4 Pages

-

dualPAK Product Information

4 Pages

-

Differential Pressure Meters

1 Pages

-

Circuit Balancing Valves

8 Pages

-

Series 4600 HSC

4 Pages

-

IPC 11550

2 Pages

-

IPS 4000

4 Pages

-

Instantaneous Water Heater

4 Pages

-

Sump and Sewage Systems

8 Pages

-

Integrated Pumping Systems

5 Pages

-

High-Efficiency Motors

6 Pages

-

Vertical MultiStage Pumps

4 Pages