Website:

ROLAND ELECTRONIC

Website:

ROLAND ELECTRONIC

Catalog excerpts

Weld Seam Control System EHR® ALUCHECK Non-destructive Control and Inspection of Weld Seam for Steel and Aluminum Laser based function principle THE ROLAND PLUS ► Automatic visual inspection ► Maintenance-free ► Secure quality control Geometrical evaluation and reliable detection of three-dimensional geometric errors ● Approaches of both types of system in one sensor: - Inspection of the surface - Inspection of the geometry - 1x3D sensor, stationary or robot-guided - 1x2D/3D sensor (Incident or transmitted light, type K), stationary or robot-guided - 1x3D sensor & 1x2D/3D sensor (Incident or transmitted light, type S), stationary or robot-guided - 2x3D sensor, stationary or robot-guided ● Absolute measuring process ● Integrated Fieldbus interface

Open the catalog to page 1

WELD SEAM CONTROL SYSTEM EHR® ALUCHECK The EHR® AluCheck System has been developed for the control of weld seams of aluminum and steel. By the usage of different sensors respectively combinations of these sensors it is possible to detect and classify all regular optical wed seam defects. Actually the system has been extended so that other types of welding (e.g. RobScan welding) allow safe quality controls too. The EHR® AluCheck System consists in the standard version of three components: - Mounting plate (here the components switch cabinet and controller (Embedded PC) are mounted.) -...

Open the catalog to page 2

WELD SEAM CONTROL SYSTEM EHR® ALUCHECK Sensor systems: The EHR® AluCheck control system is available in four versions: ● EHR® 3D AluCheck system (3D front side): 3D camera (triangulation technology). Errors differing in the spatial coordinates (width, height and position) from a good weld seam are recognized. ● EHR® 2D/3D AluCheck system (2D/3D front side): 3D camera and 2D camera are enclosed in a sensor housing. This offers the possibility to examine error characteristics by a 2D matrix image (e.g. smaller pores). ● EHR® 2D/3D AluCheck and rear side 3D AluCheck (incident light version):...

Open the catalog to page 3

WELD SEAM CONTROL SYSTEM EHR® ALUCHECK System versions EHR® 3D AluCheck 2D/3D front side Incident light Transmitted light 3D front side and 3D rear side More available versions: S=stationary, R=robot-guided One side weld seam control,1 sensor One side weld seam control,1 sensor Double side weld seam control, 2 sensors Double side weld seam control, 2 sensors Double side weld seam control, 2 sensors EHR® 2D/3D AluCheck EHR® 2D/3D + 3D AluCheck, A Transmitted light versions: type K, type S 2D/3D TIVIS weld seam sensor with connection for control line of the transmitted light illumination...

Open the catalog to page 4All ROLAND ELECTRONIC catalogs and technical brochures

-

NS9N-AAD-SC

4 Pages

-

Thickness Gauging

38 Pages

-

Angle Control Unit SIS-ACU

4 Pages

-

SHX42 Sensor bracket

4 Pages

-

Remote Service Box RSB

2 Pages

-

SND40 for tubes

4 Pages

-

SND40 for coils

4 Pages

-

ECT40

4 Pages

-

SIS Calibrator

4 Pages

-

C100

4 Pages

-

XA100

4 Pages

-

SND8S

4 Pages

-

NS9SC

4 Pages

-

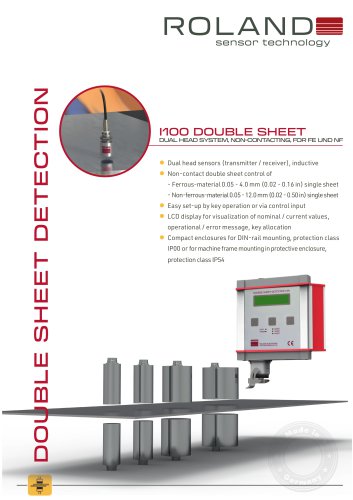

DOUBLE SHEET DETECTOR C100-S

4 Pages