Website:

PROTEM

Website:

PROTEM

Group: ttng-hd

Catalog excerpts

HIGH SPEED CUTTING AND BEVELING CTA 1-4 CTA 2-6 CTA 2-12 CTA 6-16 CTA 12-24 CTA 16-30

Open the catalog to page 1

The PROTEM CTA - HIGH SPEED CUTTING AND BEVELING MACHINE prefabrication requirements! The PROTEM CTA – HIGH SPEED CUTTING AND BEVELING MACHINE saves space in your workshop and can be integrated in your production lines for unmatched results. Pipeline Chemical Tubes and pipes with OD diameters ranging from 2” to 36” / 60.3 to 914.4 mm Power Generation will be cut and beveled within just a few seconds! Larger diameters are available Tube and Pipe Processing… upon request. The CTA serves virtually any industry where the weld quality is critical and projects must stay on schedule and on budget....

Open the catalog to page 2

Technical Features The machining unit is made of a welded structure with: • One tool holder plate • Two OD clamping systems for the pipe • Cutting principle The tube to cut and bevel is stationary. It is immobilized in the machine’s OD clamping devices. The tool bits mounted on the rotating plate are put into rotation around the tube to perform the cut. The feed and back up of the tool bits are handled entirely mechanically during the rotation of the tool holder plate. While cutting, the machine performs beveling on both ends. The tool holder carriages mounted on the rotating plate...

Open the catalog to page 3

Clamping range Machining capacity Machining time Capacity Motor power Automatic Automatic Automatic Automatic depending on the depending on the depending on the depending on the wall thickness_wall thickness_wall thickness_wall thickness depending on the depending on the depending on the depending on the wall thickness wall thickness wall thickness wall thickness Automatic 4 to 8 minutes depending on the wall thickness 6 to 10 per hour depending on the wall thickness 30 kW or 30kW x2 Automatic 3 to 6 minutes depending on the wall thickness 10 to 15 per hour depending on...

Open the catalog to page 4

MULTIFUNCTIONAL CONTROL PANEL The machine is delivered with an electric panel in accordance with the EC Standards. On the panel face, several switches and a touch screen enable users to operate the machine and access the saved machining programs. The machine can also be operated manually. The control panel allows the operator to control the functions: S Clamp /Unlock S Slow / Fast Machining S Start / Stop Machine S Direction tool holder S Lubrication S Chip conveyor S Emergency stop button PRISM CLAMPING SYSTEM The prism clamps the pipe. Accuracy and repetitive perfect weld...

Open the catalog to page 5

PROTEM A CUT ABOVE THE REST Tube storage table ••••••• Insert holder sets ••••••• TUBE CONVEYORS All tube conveyors can be used with the range of CTA machines. The tube conveyor can be delivered in various configurations to meet the customer's application requirements. The tube conveyor can be supplied with different lengths; 6 meters (20'), 8 meters (26'), 10 meters (33') or 12 meters (39'). The height adjustment makes for a very precise positioning of the tube in the mandrel. The tubes can be manually conveyed or be driven by motorized rollers. The rollers are zinc treated and...

Open the catalog to page 6

LIFTING TABLE The optional lifting table can be used with all CTA machines. The lifting table is positioned under the CTA structure. Its purpose is to align the axis tool holder plate with the tube to be machined, which must be set on a fixed tube conveyor. This option saves time and therefore increases productivity. Moreover, it offers a great ease of use due to the alignment between the axis of the tube set on a tube conveyor and the axis of the tool holder plate of the CTA. CHIPS CONVEYOR The chips conveyor can be used on all CTA machines. The productivity rate is increased as all the...

Open the catalog to page 7

OUR COMMITMENT! YOUR SATISFACTION! Serving our customers around the world with competence, efficiency and reliable service is our main goal. Whatever questions you may have, please do not hesitate to consult with us. Our staff will always advise you in a professional manner and recommend the right equipment to meet your technical requirements. Call or email us for more information!

Open the catalog to page 8All PROTEM catalogs and technical brochures

-

Welding Preparation - Turkish

100 Pages

-

Orbital Cutting Saws

12 Pages

-

WATER SOLUBLE PAPER AND TAPE

8 Pages

-

Boring Bar

1 Pages

-

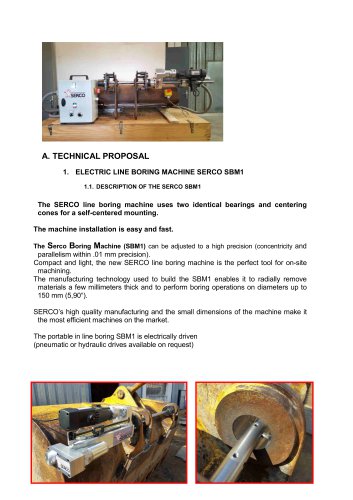

Serco SBM1

4 Pages