Website:

PROTEM

Website:

PROTEM

Group: ttng-hd

Catalog excerpts

HIGH SPEED BEVELING BENCHES PIPE RANG PIPE RANGE PIPE RANGE PIPE RANGE 24" PIPE RANGE 36" STATIONARY PIPE BEVELIN MACHINE B8- SERIES PROTEM USA LLC PROTEM SAS PROTEM GmbH 29340 Industrial Way, # 402 Z.I. Les Bosses Am Hambiegel 27 Evergreen, CO 80439| USA 26800 Etoile-sur-Rhone | FR 76706 Dettenheim | DE

Open the catalog to page 1

BB HIGH SPEED BEVELING BENCHES are the most powerful and reliable machines for achieving a perfect weld end preparation in a matter of seconds. Heat exchangers Pipeline construction and maintenance BB HIGH SPEED BEVELING BENCHES The equipment you will need for all your weld You will drastically increase your productivity with the BB – High Speed Beveling Bench! The BB – High Speed Beveling Machine serves virtually all industries where the weld quality is critical and projects must stay on schedule. The adjustable to any size of tube or pipe within the machine’s range. It will machine...

Open the catalog to page 2

BB HIGH SPEED BEVELING BENCH Used for beveling, facing and counterboring operations. These operations can be processed individually or simultaneously. They will perform repeatable high quality bevels with anI, V, J, X shape or compounded bevels. Perfectly suitable for manual or automated welding processes. BB HIGH SPEED BEVELING MACHINES Can achieve perfect weld preparations on virtually all materials; carbon steel, stainless steel, exotic alloys such as INCOLOY, HASTELLOY, DUPLEX and SUPER DUPLEX. ADVANTAGES : Self-centering clamping Very Powerful electric motors...

Open the catalog to page 3

PROTEM BB- SERIES BB 1-6 BB3-16 BB 12-24 BB24-36 BB36-48 Clamping range 1” to 6” 3” to 16” 12” to 24” 24” to 36” Machining capacity Clamping process Feed stroke 25,4 mm (1”) Manual Semi automatic Automatic 100 mm (3.94”) Manual Manual Manual Semi automatic Semi automatic Semi automatic Automatic Automatic Automatic Feed operation Machining time Motor power Manual Manual Manual Manual Manual Automatic Automatic Automatic Automatic Automatic Few sec°nds Few seconds Few seconds Few seconds Few seconds Machining Carbide...

Open the catalog to page 4

MULTIFUNCTIONAL CONTROL PANEL S Stop feed S Lubrication S Chip conveyor S Emergency stop button The machine is delivered with an electric panel in accordance with EC Standards. On the face of the panel are several switches and a screen that operate the machine. The end user can use the manual mode. The control panel allows the user to control all important functions: S Clamp /Unlock S Slow / Fast Machining S Start / Stop Machine PRISM CLAMPING SYSTEM The prism shaped jaws clamp to any size pipe in the machine’s range. The clamping system ensures weld end preparations, with the highest...

Open the catalog to page 5

Automatic clamping device Semi-automatic clamping Automatic feed Semi-automatic feed Lifting table Roller benches Insert holder sets Chip conveyor Tube storage table MACHINING TABLE FOR ELBOWS Designed for machining elbows, this option allows you to quickly and easily machine elbows of all sizes. TUBE CONVEYORS The tube conveyor can be delivered in various configurations to meet the customer’s application requirements. The tube conveyor can be supplied with different lengths; 6 meters (20 feet), 8 meters (26 feet), 10 meters (33 feet) or Their height adjustment enables a very precise...

Open the catalog to page 6

TUBE STORAGE TABLE All the feeding tube conveyors or storage tube conveyors can be easily incorporated into any machine in the BB range. The length of the feeding or storage tube conveyor is adapted to the length of the tube conveyor. CHIPS CONVEYOR The optional chips conveyor can be used on all versions of the BB. The productivity rate is greatly increased as all the chips produced during a machining cycle are removed automatically. This option brings a real ease of use for the operator as it is not necessary to stop the machining operation to remove the chips. LUBRICATION DEVICE Increases...

Open the catalog to page 7

LIFTING TABLE The optional lifting table can be used with all BB versions. The lifting table is positioned under the BB structure. Its purpose is to align the axis of the tool holder plate with the axis of the tube. The tube to be machined must be dually supported by the tube conveyor and the clamping jaws of the BB. This option saves setup time thereby helping to increase productivity. Moreover, it offers great ease of use due to the alignment between the axis of the tube set on a tube conveyor and the axis of the tool holder plate of the BB. CLAMPING JAWS WRAP To avoid deforming tubes...

Open the catalog to page 8

jE+D +R+T N"1 V - Bevel N‘2 V - Bevel with internal beveling N"3 J - Bevel N‘4 J - Bevel with internal beveling N°5 - Internal and external bevel N°6 - Compound bevel - various combinations of beveling angles possible N°7 - Compound bevel with internal beveling - various combinations of beveling angles possible N°8 - J - Bevel + Compound with various combinations of beveling angles possible N°9 - J - bevel + Compound + internal with various combinations of beveling angles possible with internal beveling All the above mentioned machining types can be processed individually or simultaneously...

Open the catalog to page 9

PROTEM A CUT ABOVE THE REST OUR COMMITMENT! YOUR SATISFACTION! Serving our customers around the world with competence, efficiency and reliable service is our main goal. Whatever questions you may have, please do not hesitate to consult with us. Our staff will always advise you in a professional manner and recommend the right equipment to meet your technical requirements. Call or email us for more information! All information, pictures, drawings showed in the present document are non contractual and can be modified without any prior notice

Open the catalog to page 10All PROTEM catalogs and technical brochures

-

Welding Preparation - Turkish

100 Pages

-

Orbital Cutting Saws

12 Pages

-

WATER SOLUBLE PAPER AND TAPE

8 Pages

-

Boring Bar

1 Pages

-

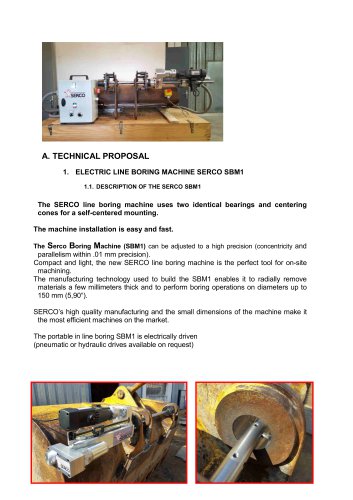

Serco SBM1

4 Pages