Website:

DELLNER BUBENZER Germany GmbH

Website:

DELLNER BUBENZER Germany GmbH

Catalog excerpts

Brake Systems for Container Cranes. Safety. PINTSCH BUBENZER A Schaltbau Company

Open the catalog to page 1

Thruster Disc Brakes Hydraulic Disc Brakes Electromagnetic Disc Brakes Drum Brakes, Band Brakes Couplings, Hubs, Discs, Drums Monitoring Systems, Control Systems Storm Brakes

Open the catalog to page 2

Thruster Disc Brake SB 23/SB 28/SB 38 PINTSCH BUBENZER is certified according to DIN EN ISO 9001:2008 High Performance Robust Design Easy Maintenance

Open the catalog to page 3

Main Features Patented self-centering of brake levers Limit switch release control Automatic wear compensator Limit switch wear control Sintered linings for high friction speeds Limit switch manual release Continuously adjustable brake spring with torque scale and wear bushing enclosed in a spring tube Manual release lever with or without lock Stainless steel pins and spindles Brake discs with hubs or couplings Monitoring systems (e.g. VSR/CMB) Maintenance-free bushings in all hinge points Symmetric design W-execution (special anti-corrosion protection) Ordering Example Thrusters, Technical...

Open the catalog to page 4

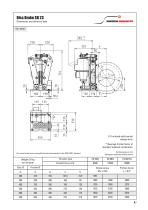

Disc Brake SB 23 Dimensions and technical data Rev. 05-08 1) If ordered with manual release lever *) Average friction factor of standard material combination All dimensions in mm Alterations reserved without notice For crane brake layout use safety factors documented in the FEM 1.001, Section 1 Thruster type

Open the catalog to page 5

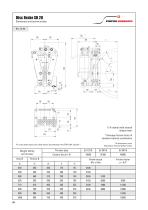

Disc Brake SB 28 Dimensions and technical data Rev. 10-08 1) If ordered with manual release lever *) Average friction factor of standard material combination All dimensions in mm Alterations reserved without notice For crane brake layout use safety factors documented in the FEM 1.001, Section 1 Thruster type

Open the catalog to page 6

Disc Brake SB 28 Dimensions and technical data Rev. 10-08 1) If ordered with manual release lever *) Average friction factor of standard material combination For crane brake layout use safety factors documented in the FEM 1.001, Section 1 All dimensions in mm Alterations reserved without notice Thruster type Brake torque MBr in Nm Friction factor μ = 0,4*

Open the catalog to page 7

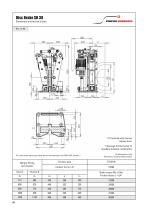

Disc Brake SB 38 Dimensions and technical data Rev. 12-06 1) If ordered with manual release lever *) Average friction factor of standard material combination For crane brake layout use safety factors documented in the FEM 1.001, Section 1 All dimensions in mm Alterations reserved without notice Thruster type Brake torque MBr in Nm Friction factor μ = 0,4*

Open the catalog to page 8

Thruster Disc Brakes SB 8 Series PINTSCH BUBENZER is certified according to DIN EN ISO 9001:2008 Compact Design Robust Construction Easy Maintenance

Open the catalog to page 9

Main Features Compact dimensions Automatic wear compensator Ideal for belt conveyors in combination with long stroke thrusters Limit switch release control Sintered linings for high friction speeds Limit switch manual release Organic, non-asbestos linings for low friction speeds Manual release lever with or without lock Continuously adjustable brake spring with torque scale and wear bushing enclosed in a spring tube Brake discs with hubs or couplings Limit switch wear control Monitoring systems (e.g. VSR/CMB) Stainless steel pins and spindles Maintenance-free bushings in all hinge points...

Open the catalog to page 10

Disc Brake SB 8.11 Dimensions and technical data Rev. 10-08 (Replaces SB 14.11, identical dimensions) Manual release lever Right-hand execution Left-hand execution *) Average friction factor of standard material combination All dimensions in mm Alterations reserved without notice For crane brake layout use safety factors documented in the FEM 1.001, Section 1 Thruster type

Open the catalog to page 11

Disc Brake SB 8.1 Dimensions and technical data Rev. 01-08 *) If ordered with manual release lever Right-hand execution Left-hand execution *) Average friction factor of standard material combination All dimensions in mm Alterations reserved without notice For crane brake layout use safety factors documented in the FEM 1.001, Section 1 Thruster type

Open the catalog to page 12

Disc Brake SB 8.2 Dimensions and technical data Rev. 12-06 *) If ordered with manual release lever Right-hand execution Left-hand execution *) Average friction factor of standard material combination All dimensions in mm Alterations reserved without notice For crane brake layout use safety factors documented in the FEM 1.001, Section 1 Thruster type

Open the catalog to page 13

Disc Brake SB 8.3 Dimensions and technical data Rev. 06-13 *) If ordered with manual release lever Dimension a: With automatic wear compensator max. 280 mm without automatic wear compensator max. 220 mm Right-hand execution Left-hand execution *) Average friction factor of standard material combination All dimensions in mm Alterations reserved without notice For crane brake layout use safety factors documented in the FEM 1.001, Section 1 Thruster type

Open the catalog to page 14

Disc Brake SB 22 Dimensions and technical data Rev. 12-06 Right-hand execution Motor or Gearbox vertical mounted Left-hand execution *) Average friction factor of standard material combination All dimensions in mm Alterations reserved without notice For crane brake layout use safety factors documented in the FEM 1.001, Section 1 Thruster type

Open the catalog to page 15

Hydraulic Caliper Disc Brakes SF Series PINTSCH BUBENZER is certified according to DIN EN ISO 9001:2008 High Performance Robust Design Easy Maintenance

Open the catalog to page 17

Main Features Two identical caliper halves, ready for operation, with spring packs set to nominal force and limit switch release control Options Limit switch wear control Sintered linings Complete piped supports for one or more calipers Up to 2 mm air gap between brake pad and disc Hydraulic power units Easy, manual pad wear compensation Special seals for flameproof fluids Organic, non-asbestos linings Cleaning pads Brake discs CMB contact force measurement Applications The high capacity of these brakes makes them particularly suitable as secondary emergency brakes on hoist gears and on...

Open the catalog to page 18

Disc Brake SF Dimensions and technical data Rev. 12-06 Bleeder valve Pressure connection Data per caliper half *) Average friction factor of standard material combination All dimensions in mm. Alterations reserved without notice. d8 h1 h2 h3 l1 l2 l3 l4min Bolt ø Bolt material Tighten. torque, Nm Contact force FA kN Op. pressure bar Max. pressure bar Release stroke mm Oil volume l 2 Pad surface cm Theor. friction µ* Weight (kg) Brake torque MBr in Nm = FA (kN) x µ x d1 (mm) Brake disc data Please indicate required mounting position. d4 = d2-420 mm d2-420 mm d2-490 mm d2-620 mm d2-700 mm d2...

Open the catalog to page 19All DELLNER BUBENZER Germany GmbH catalogs and technical brochures

-

Brake System For Eot Cranes

70 Pages

-

Wind power

48 Pages

-

Brake systems for steel mills

91 Pages

-

Motor mounted Brakes

32 Pages

-

Couplings

56 Pages

-

buel

32 Pages

-

Brochure Crane systems

76 Pages

-

Brochure "Mining"

96 Pages

-

Brochure "Ship's chandlery"

46 Pages

-

Imagebrochure "PINTSCH BUBENZER"

20 Pages