Website:

DELLNER BUBENZER Germany GmbH

Website:

DELLNER BUBENZER Germany GmbH

Catalog excerpts

BRAKE SYSTEMS FOR EOT CRANES BRAKING UNLIMITED

Open the catalog to page 1

Disc Brake SB 28.3 / SB 23.3 with BUEL® PINTSCH BUBENZER BRAKE SYSTEMS FOR EOT CRANES PINTSCH BUBENZER CONTENT Thruster Disc Brakes 3 - 16 Pneumatic Disc Brakes 17 - 24 Hydraulic Disc Brakes 25 - 43 Electromagnetic Disc Brakes 45 - 65 Drum Brakes, Band Brakes 67 - 83 Couplings, Hubs, Discs, Drums 85 - 101 Monitoring Systems, Control Systems 102 - 115 PINTSCH BUBENZER is certified according to

Open the catalog to page 2

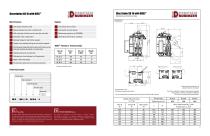

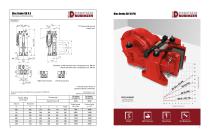

Disc Brake SB 28.3 with BUEL® Dimensions and technical data PINTSCH BUBENZER Main Features BUEL® Thrusters, Technical Data Ordering Example Brake type Disc diameter Please Note We supply a detailed operating manual with every order. Nevertheless, we would point out that brakes are only as safe as the servicing and maintenance performed while they are in operation. The guarantee for the correct functioning of our brakes is only valid if the user adheres to the German DIN standard 15434 part 2 (drum and disc brakes, servicing and maintenance in operation), or to comparable standards in his...

Open the catalog to page 3

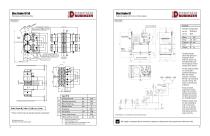

Dimensions and technical data Disc Brake SB 16 with BUE1® PI NT SC K BUBENZER Rev. 08-16 *) Average static friction factor of standard material combination The friction coefficient is subject to fluctuations depending on operational-, material- and ambient-conditions! This must be considered during the selection! All dimensions in mm Alterations reserved without notice For crane brake layout use safety factors documented in the FEM 1.001, Section 1 Weight without thruster: ca. 99 kg

Open the catalog to page 4

Disc Brake SB 16 with BUH® Dimensions and technical data PINTSCH BUBENZER Main Features Options BUEL® Thrusters, Technical Data Thruster Type 1.5 times of nominal current Ordering Example Please Note We supply a detailed operating manual with every order. Nevertheless, we would point out that brakes are only as safe as the servicing and maintenance performed while they are in operation. The guarantee for the correct functioning of our brakes is only valid if the user adheres to the German DIN standard 15434 part 2 (drum and disc brakes, servicing and maintenance in operation), or to...

Open the catalog to page 5

Thruster Disc Brakes SB 8 Series PINTSCH BUBENZER is certified according to DIN EN ISO 9001:2015 Compact Design Robust Design Easy Maintenance

Open the catalog to page 6

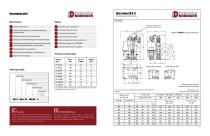

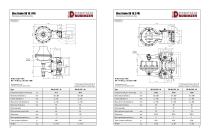

Dimensions and technical data PINTSCH BUBENZER Main Features Thrusters, Technical Data Ordering Example Brake type Disc diameter Disc thickness Thruster Type Data supplied by thruster manufacturer, please take higher start current into consideration, fuses to be minimum 2A Thruster type R = Right hand L = Left hand Please Note We supply a detailed operating manual with every order. Nevertheless, we would point out that brakes are only as safe as the servicing and maintenance performed while they are in operation. The guarantee for the correct functioning of our brakes is only valid if the...

Open the catalog to page 7

Dimensions and technical data Disc Brake SB 8.2 Dimensions and technical data Right-hand execution Left-hand execution release lever standard material combination For crane brake layout use safety factors documented in the FEM 1.001, Section 1 All dimensions in mm Alterations reserved without notice

Open the catalog to page 8

Dimensions and technical data PI NT SC K BUBENZER *) If ordered with manual release lever Dimension a: With automatic wear compensator max. 280 mm without automatic wear compensator max. 220 mm For crane brake layout use safety factors documented in the FEM 1.001, All dimensions in mm Section 1 Alterations reserved without notice PINTSCH BUBENZER is certified according to DIN EN ISO 9001:2015 Average friction factor of standard material combination

Open the catalog to page 9

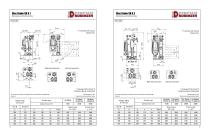

Disc Brake SB 18 PXi Dimensions and technical data PINTSCH BUBENZER Main Features Operating Restrictions ■ Requires manual adjustment of air gap to compensate for pad wear ■ High capacity units need lifting equipment for installation Can be used in all industrial applications where pneumatic supply is available. Such as • Wire and steel rope manufacturing, used as tensioners • Paper mills, tensioning and emergency • Forestry equipment, crushers Special reference is made to the steel industry in all machines used in the process lines such as • coilers/uncoilers • transfers • slitters •...

Open the catalog to page 10

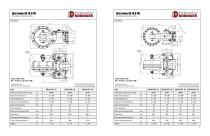

Dimensions and technical data Disc Brake SB 18.2 PXi Dimensions and technical data

Open the catalog to page 11

Brake torque in Nm Mbr = Fa (N) x p x d1 (mm) / 1000 All dimensions in mm Alterations reserved without notice *) Theoretical friction factor of standard material combination Brake disc diameter d2 Brake disc thickness Max. pad wear (each side) Piston area Theor. friction coefficient Disc Brake SB 18.8 PXi Dimensions and technical data

Open the catalog to page 12

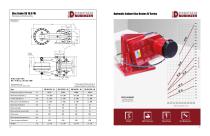

Dimensions and technical data Hydraulic Caliper Disc Brakes SF Series All dimensions in mm *) Theoretical friction factor of Alterations reserved without notice standard material combination PINTSCH BUBENZER is certified according to DIN EN ISO 9001:2015

Open the catalog to page 13

Main Features Options Two identical caliper halves, ready for operation, with spring packs set to nominal force and limit switch release control Up to 2 mm air gap between brake pad and disc Easy, manual pad wear compensation Organic, non-asbestos linings Applications I The high capacity of these brakes makes them particularly suitable as secondary emergency brakes on hoist gears and on downhill conveyor I Other applications are possible in material handling, requiring power and compact design in either direction of rotation, particularly in replacing band brakes I Brakes for use in high...

Open the catalog to page 14

Dimensions and technical data Disc Brake SF Hydraulic power unit for one or more calipers *) Theor. friction factor of standard material combination d2 = Brake disc diameter in mm d1 = Friction diameter in mm d< = Max. permissible drum or hub diameter in mm b1 = Brake disc thickness in mm (min. 30) The flow diagram shows the general arrangement of the hydraulic power unit, including hand pump for emergency manual release of the brakes. The two solenoid valves are connected in parallel (redundancy). After the nominal pressure is reached, the idler valve switches into idle running. The motor...

Open the catalog to page 15All DELLNER BUBENZER Germany GmbH catalogs and technical brochures

-

Wind power

48 Pages

-

Brake systems for steel mills

91 Pages

-

Motor mounted Brakes

32 Pages

-

Couplings

56 Pages

-

buel

32 Pages

-

Brochure Crane systems

76 Pages

-

Brochure "Mining"

96 Pages

-

Brochure "Ship's chandlery"

46 Pages

-

Imagebrochure "PINTSCH BUBENZER"

20 Pages