Website:

PALAMATIC

Website:

PALAMATIC

Catalog excerpts

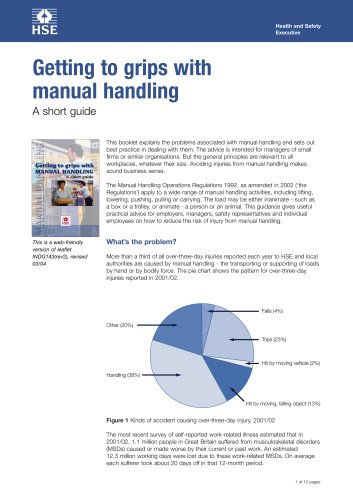

Health and Safety Executive This booklet explains the problems associated with manual handling and sets outbest practice in dealing with them. The advice is intended for managers of small firms or similar organisations. But the general principles are relevant to all workplaces, whatever their size. Avoiding injuries from manual handling makes sound business sense. The Manual Handling Operations Regulations 1992, as amended in 2002 (theRegulationsђ) apply to a wide range of manual handling activities, including lifting, lowering, pushing, pulling or carrying. The load may be either inanimate - such as abox or a trolley, or animate - a person or an animal. This guidance gives useful practical advice for employers, managers, safety representatives and individual employees on how to reduce the risk of injury from manual handling. > This is a web-friendlyversion of leafletINDG143(rev2), revised03/04 More than a third of all over-three-day injuries reported each year to HSE and local authorities are caused by manual handling - the transporting or supporting of loads by hand or by bodily force. The pie chart shows the pattern for over-three-day injuries reported in 2001/02. The most recent survey of self-reported work-related illness estimated that in2001/02, 1.1 million people in Great Britain suffered from musculoskeletal disorders (MSDs) caused or made worse by their current or past work. An estimated 12.3 million working days were lost due to these work-related MSDs. On average each sufferer took about 20 days off in that 12-month period. > Other (20%)Handling (38%) Falls (4%)Trips (23%)Hit by moving vehicle (2%)Hit by moving, falling object (13%) Figure 1 Kinds of accident causing over-three-day injury, 2001/02 > 1of 12 pages size="-2">

Open the catalog to page 1

Health and Safety Executive Manual handling injuries can occur wherever people are at work - on farms andbuilding sites, in factories, offices, warehouses, hospitals, banks, laboratories, and while making deliveries. Heavy manual labour, awkward postures, manual materials handling, and previous or existing injury are all risk factors implicated in the development of MSDs. More information and advice on MSDs is available on the HSE website, including advice on managing back pain at work (see Further readingђ).Prevention and control of MSDs, such as manual handling injuries, has...

Open the catalog to page 2

Health and Safety Executive Check whether you need to move it at all For example: > ■ does a large workpiece really need to be moved, or can the activity (egwrapping or machining) safely be done where the item already is? For example: > ■ can you take the treatment to the patient, not vice versa? > ■ can raw materials be piped to their point of use? Consider automation, particularly for new processes Think about mechanisation and using handling aids > ■ aconveyor; > ■ apallet truck; > ■ an electric or hand-powered hoist; > ■ alift truck.But beware of new hazards from automation or...

Open the catalog to page 3

It is often useful to record and keep the main findings, and this should always bedone if it would be difficult to repeat the assessment. However, an assessment need not be recorded if: > Health and Safety Executive Do assessments need to be recorded? What role can employees and their representatives play in carrying out assessments? Your employees can help you carry out the assessment - they often know whatproblems there are and how best to solve them. If their work is varied or not closely supervised, make sure they are aware what risks to look for when manual handling, and what to do...

Open the catalog to page 4

Health and Safety Executive Table 1 Making an assessment (continued on next page) > The tasks, do they involve: Can you: > ■ holding loads away from the body? > ■ use a lifting aid? > ■ twisting, stooping or reaching upwards? > ■ improve workplace layout to improveefficiency? > ■ large vertical movement? > ■ reduce the amount of twisting and stooping? > ■ long carrying distances? > ■ avoid lifting from floor level or above shoulder height, especially heavy loads? > ■ strenuous pushing or pulling? > ■ repetitive handling? > ■ reduce carrying distances? > ■ insufficient rest or recovery time?...

Open the catalog to page 5

Health and Safety Executive Table 1 Making an assessment (continued from previous page) > Individual capacity, does the job: Can you: > ■ require unusual capability, eg above-averagestrength or agility? > ■ pay particular attention to those who have aphysical weakness? > ■ endanger those with a health problem or learning/physical disability? > ■ take extra care of pregnant workers? > ■ give your employees more information, eg about the range of tasks they are likely to face? > ■ endanger pregnant women? > ■ call for special information or training? > ■ provide more training (see What about...

Open the catalog to page 6

Health and Safety Executive How far must I reduce the risk? Tothe lowest level reasonably practicableђ. That means reducing the risk until thecost of any further precautions - time, effort or money - would be far too great in proportion to the benefits. You should definitely provide mechanical aids if it is reasonably practicable to do so and the risks identified in your risk assessment can be reduced or eliminated by this means. But you should consider mechanical aids in other situations as well - they can improve productivity as well as safety. Even something as simple as a sack truck can...

Open the catalog to page 7

Health and Safety Executive ■ Keep the load close to the waist. Keep the load close to the body for as longas possible while lifting. Keep the heaviest side of the load next to the body. If a close approach to the load is not possible, try to slide it towards the body before attempting to lift it. > ■ Adopt a stable position. The feet should be apart with one leg slightly forwardto maintain balance (alongside the load, if it is on the ground). The worker should be prepared to move their feet during the lift to maintain their stability. Avoid tight clothing or unsuitable footwear, which may...

Open the catalog to page 8All PALAMATIC catalogs and technical brochures

-

Reel Lifting

2 Pages

-

Drum Lifting

2 Pages

-

Vacuum Lifting

3 Pages

-

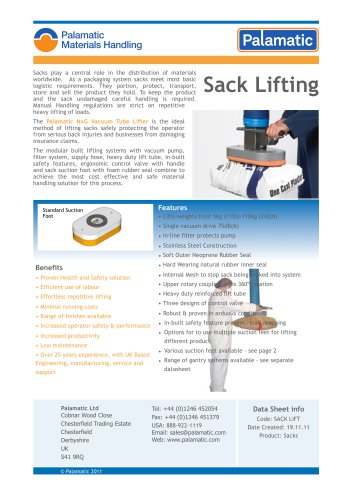

Sack Lifting

2 Pages

-

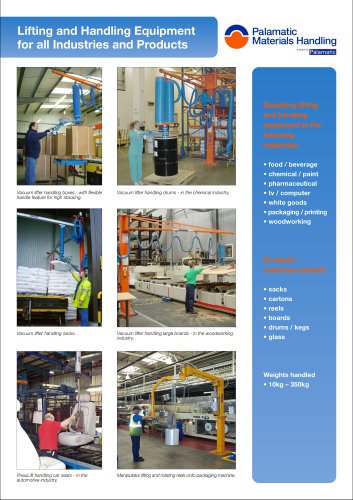

Palamatic Materials Handling

11 Pages

-

PalPharma Handling Solutions

8 Pages

Archived catalogs

-

Manual handling guidebook

12 Pages

-

Palamatic Lifting Range

2 Pages