Website:

OMVE Lab & Pilot Equipment

Website:

OMVE Lab & Pilot Equipment

Catalog excerpts

Comprehensive Carbonators for RTD Carbonated Beverages CF210 Carbo-Fill® The CF210 Carbo-Fill® carbonator stands as a hallmark of reliability and precision in multi-functional carbonation technology. With over 30 years of trusted performance, the CF210 series has become the industry benchmark for its capability to replicate industrial processes for beverages on a miniature scale. The advanced engineering of the CF210 series allows for precise carbonation control, capable of dissolving up to llg/l of C02 in liquid. This feature provides R&D teams with the versatility to experiment and innovate with new beverage concepts. With user-friendly touchscreen controls, users can effortlessly set and store different carbonation and filling scenarios, streamlining the R&D process. The CF210 is designed for ease of installation, setup, and operation, offering a comprehensive solution that combines cooling, carbonation, counter-pressure filling, and closing in one efficient station. • Reproduces any carbonated product on the market • Very compact with integrated cooling system • Pre-mix and post-mix capability The integrated chiller is cooling the product to carbonation temperature. An injector injects C02 into the product, ensuring full absorption at the required level without causing foaming. Saturation takes about 1 liter per minute, after which the filling process can start. During the filling cycle, the packaging is positioned at the filling point and flushed with C02. The packaging is pressurized and filled with the carbonated water, followed by depressurization, after which the packaging travels down the line for retrieval.

Open the catalog to page 1

• Water • Juices & Concentrates • Soft drinks • Coffee and Tea • Beer & Alcoholic drinks Optional Accessories • Automatic dosing system for post-mix drinks, saving time and providing quick results • Integrated sealers for crown corks and screw caps • Multiple filling heads: adaptable filling heads for small to large cans, glass, or PET bottles • Built-In vacuum pump: for product deaeration before carbonation and deaeration of bottles before filling • Hot filling capability: allows integration with external pasteurization or UHT system for filling for non-carbonated, hot-filled products •...

Open the catalog to page 2All OMVE Lab & Pilot Equipment catalogs and technical brochures

-

OMVE CF310 Batch Carbonator

2 Pages

-

OMVE HT220 HTST/UHT System

2 Pages

-

OMVE FS211 Clean-Fill ESL

2 Pages

-

OMVE FS212 Asepto-Fill

2 Pages

-

OMVE CRA225 Crystallizer

2 Pages

-

OMVE MPV Batch Cooker

2 Pages

-

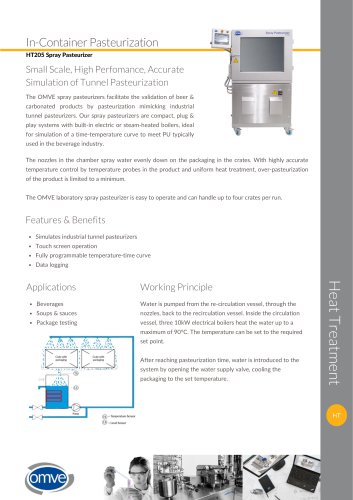

OMVE HT205 Spray Pasteurizer

2 Pages

-

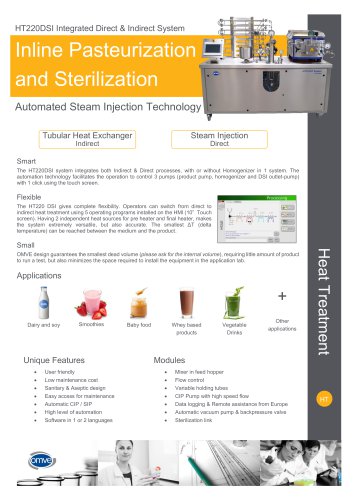

OMVE HT220DSI

2 Pages