Website:

OMEGA AIR d.o.o. Ljubljana

Website:

OMEGA AIR d.o.o. Ljubljana

Catalog excerpts

WATER/OIL SEPARATORS - WOS Product overview

Open the catalog to page 1

Water/oil separators Condensate treatment BASIC PRINCIPLES CLEAN WATER OUTLET residual oil content <10ppm 2 WOSm water/oil separator WOSm series is intended for reliable oil separation from condensate. Since the adsorption catridge is replacable, maintenance is quick and clean. The condensate enters into the separator under pressure via the depressurisation chamber. It contains a filter, which prevents the condensate to be relieved to the ambient. The condensate enters into the separator under pressure via the depressurisation chamber with air filter. The condensate then travels to the 1st...

Open the catalog to page 2

CLEAN WATER OUTLET residual oil content <10ppm Condensate is always present in the compressed air systems. As a result of the operation of the oil lubricated compressors also contains about 1% oil. Even small quantities can have harmful effect on downstream equipment and processes. Condensate from lubricated compressed air systems must be disposed of in a responsible manner, in accordance with local regulations and by laws. Therefore, should not be discharged directly into the environment, first of all, oil must be separated from the water. Oil /water separator is a device that performs...

Open the catalog to page 3

Water/oil separators WOSm SERIES WATER - OIL SEPARATORS operating temp. range inlet connection APPLICATIONS • compressed air systems • suitable for installation inside compressors • compressed air dryers • condensate separators • pressure vessels DESCRIPTION WOSm water oil separators have been developed to separate lubricant oil from condensate generated in compressed air systems. Due to patented technology regular service can be done in 30 seconds without any cleaning. Separation begins in “cyclonic depressurization chamber” and continues in “filter cartridge”. When the “filter cartridge”...

Open the catalog to page 4

WOSm - TECHNICAL DATA Operating temperature 1,5 - 45 °C (max 65 °C)(1); 35 - 113 °F (max. 149 °F)(1) Operating media Condensate (air, water, oil); Non agresive; Not suitable for emulsion Residual oil content < 20ppm Service interval When first of following parametres appears: - 4000 operating hours of compressor - 12 months regardless of compressor operating hours Cold climate zone Mild climate zone Hot climate zone 15 °C 60 %RH 25 °C 60 %RH 40 °C 100 %RH Technical data - when all white polypropylene media becomes yellow Max. operating temperature is 65 °C, but when temperature is over 45...

Open the catalog to page 5

WATER - OIL SEPARATORS ø10 temperature oper. range 1,5 to 45 °C inlet connection APPLICATIONS • compressed air systems DESCRIPTION WOS water oil separators have been developed to separate lubricant oil from condensate from compressed air(1) systems. WOS water-oil separator can be used in variety of applications. For applications not listed please contact producer or your local distributor. Water quality test Water quality test should be performed at least once per month, to control the contamination level of disposed condensate. If oil concentration is reached, oil filter cartridges must be...

Open the catalog to page 6

WOS - TECHNICAL DATA Operating temperature 1,5 - 45 °C (max 65 °C)(3); 35 - 113 °F (max. 149 °F)(3) Operating media Condensate (air, water, oil); Non agresive; Not suitable for emulsion Residual oil content < 10ppm C Service interval When first of following parametres appears: - 4000 operating hours of compressor (4) - 12 months regardless of compressor operating hours - outlet oil concentration reaches concentration determined with local directives Cold climate zone 15 °C 60 %RH Mild climate zone 25 °C 60 %RH Technical data Max. operating temperature is 65 °C, but when temperature is over...

Open the catalog to page 7

COMPRESSED AIR TREATMENT Product catalogue COMPRESSED AIR FILTER ELEMENTS Product overview Product overview OMEGA AIR ALTERNATIVE FILTER ELEMENTS Product catalogue Cesta Dolomitskega odreda 10 SI-1000 Ljubljana, Slovenia www.omega-air.si Eurotec Ring 15 D-47445 Moers, Deutschland www.omega-air.de CMP Savica Šanci 113 HR-10000 Zagreb, Croatia www.omega-air.hr COMPRESSED AIR DRYERS Product overview

Open the catalog to page 8All OMEGA AIR d.o.o. Ljubljana catalogs and technical brochures

-

Catalogue - Product overview

72 Pages

-

Screw compressors MA SD 2-3

2 Pages

-

MA SD 7,5-15 VS /BDK

2 Pages

-

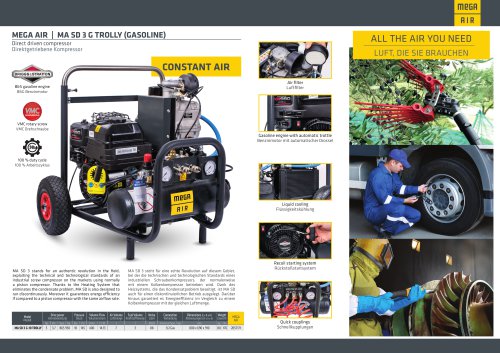

Piston compressors - MEGA AIR

12 Pages

-

Container and Skid units

8 Pages

-

WFIF SERIES

2 Pages

-

WHFIT SERIES

2 Pages

-

MEGA TOOLS

12 Pages

-

MEGA AIR QUALITY OILS

8 Pages

-

CO2-R-DRY series

2 Pages

-

ACW series

1 Pages

-

ACA series

1 Pages

-

RDHP series

2 Pages

-

RDF

2 Pages

-

RDL series

2 Pages

-

RDP series

2 Pages

-

M-DRY series

2 Pages

-

HP-DRY series

2 Pages

-

R-DRY BVL series

2 Pages

-

R-DRY BP series

2 Pages

-

COM-DRY series

2 Pages

-

X-DRY series

2 Pages

-

A-DRY TAC

2 Pages

-

A-DRY BI+BM series

2 Pages

-

PV

2 Pages

-

AIR AND GAS Product overview

2 Pages

-

Compact oxygen generators

2 Pages

-

Compact nitrogen generators

2 Pages

-

SKID based solutions

2 Pages

-

Biogas plants

8 Pages

-

OCI

1 Pages

-

CKL-IHP series

2 Pages

-

SF series

2 Pages

-

WFIW series

2 Pages

-

MSS

2 Pages

-

MDH 400

1 Pages

-

CHI

1 Pages

-

VPG 60

1 Pages

-

FA - flange adapter

1 Pages

-

TD 400M series

1 Pages

-

AOK 50SS

1 Pages

-

EVD series

1 Pages

-

RC-DRY series

2 Pages

-

HPR-DRY series

2 Pages

-

TAC HP series

2 Pages

-

A-CAT series

2 Pages

-

SFH HP

2 Pages

-

TP PED series

2 Pages

-

TP ASME series

1 Pages

-

TP series

1 Pages

-

BS TOWER

1 Pages

-

PETRO-PACK

1 Pages

-

AWS

1 Pages

-

BS 12-3,5

1 Pages

-

AIRWATT series

2 Pages

-

B-AIR plus series

2 Pages

-

OWT

2 Pages

-

OWE/HWE

2 Pages

-

OWB

2 Pages

-

OBE SERIES

2 Pages

-

ECD-B series

2 Pages

-

MDHI 50

1 Pages

-

BF series

2 Pages

-

HPF series

2 Pages

-

AK- assembly kit for filters

1 Pages

-

IHP series

2 Pages

-

PF series

2 Pages

-

EPG 60

1 Pages

-

MDM40

1 Pages

-

OCI

1 Pages

-

AV series

2 Pages

-

SPF series

2 Pages

-

CS /CS SS series

2 Pages

-

SFH /SFH SS series

2 Pages

-

CKL-CHP series

2 Pages

-

MDM60

1 Pages

-

MDH

1 Pages

-

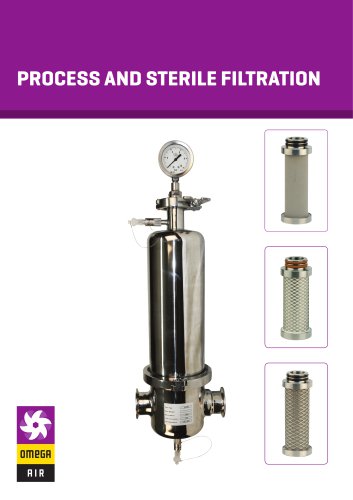

PROCESS AND STERILE FILTRATION

12 Pages

-

SORBEO Adsorbents

2 Pages