Website:

OMEGA AIR d.o.o. Ljubljana

Website:

OMEGA AIR d.o.o. Ljubljana

Catalog excerpts

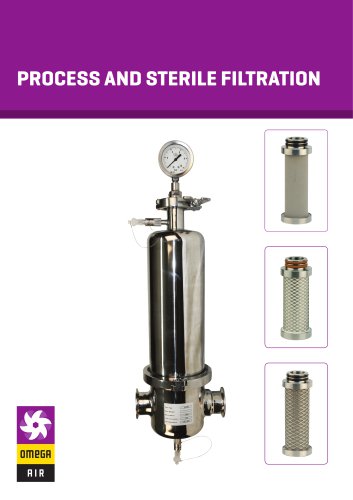

PROCESS AND STERILE FILTRATION

Open the catalog to page 1

Process and sterile filtration AIR AND GAS TREATMENT Since 1988 OMEGA AIR is developing and manufacturing quality solutions for treatment of industrial as well as process air and gas. Due to constant investment in research and development and in new production tehnologies we can offer one of the most comprehensive ranges of products for general purpose process filtration, steam filtration, sterile filtration and sterile ventilation of tanks. TYPICAL APPLICATIONS TYPICAL INDUSTRIES • Aseptic processing • Aseptic packaging • PET bottle blowing • Moving ingredients • Tank ventilation • General...

Open the catalog to page 2

Process and sterile filtration PROCESS AIR/GAS SYSTEM Due to contaminants such as solid particles, moisture, hydrocarbons or bacteria compressed air/gas when used in process can harm and cause quality and efficiency problems. Applications in process industry require compressed air or gas where above mentioned contaminants are removed or reduced to acceptable level for specific application. LEGEND 1 stainless steel process filter, PN filter element 2 stainless steel process filter, PPF filter element 3 stainless steel sterile filter, VSF filter element 4 steam generator 5 steam filter, PIW...

Open the catalog to page 3

Process and sterile filtration WHAT IS STERILE AIR In process filtration applications “sterile” refers to “free from live bacteria or other microorganisms”. SIZE OF BACTERIA Size Comparison Chart 0.001 Scanning Electron Microscope Technical Denitions Optical Microscope Visible to Naked Eye Dust Fume Mist Clay Atmospheric Conditions Spray Silt Fine Sand Mold Spores Relative Size of Typical Airborne Particulates Human Hair Cement Dust Virus Bacteria Fertilizer Carbon Black Pollen Tobacco Smoke Colloidal Silica Coal Dust Lint Beach Sand Milled Flour HOW TO PRODUCE STERILE AIR To produce...

Open the catalog to page 4

Process and sterile filtration STERILIZATION IN PLACE (SIP) where filter or even larger segments of installation are sterilized with stream of steam flowing through complete filter installation. This procedure is done in place of use without removing any parts from the installation. bar t_°C AUTOCLAVE sterilization where filter element or in some cases even complete filter housing is removed from installation and sterilized in autoclave. Autoclave is a device used to sterilize products by subjecting them to high pressure saturated steam. Frequency of sterilization depend on specific...

Open the catalog to page 5

Process and sterile filtration STAINLESS STEEL PROCESS FILTERS operating pressure PI volume flow rate side connections body connections operating temp. range material 5; 25 µm stainless steel mesh 16 (10, 12) bar 75 to 21.120 Nm3/h 1/4" to 3" threded up to DN200 flanged DIN11851 (milk pipe con.) up to 150 °C stainless steel 1.4301 DESCRIPTION PF process filter housings have been developed for applications in process industry, where the risk for corrosion of compressed air(1) system components is very high. To meet the required compressed air quality(2) appropriate filter element must be...

Open the catalog to page 6

Process and sterile filtration HIGH PRESSURE STAINLESS STEEL PROCESS FILTERS operating pressure volume flow rate side connections body connections operating temp. range material 0,01 µm borosilicate micro fibres DESCRIPTION HPF process filter housings have been developed for applications in process industry, where the risk for corrosion of compressed air(1) system components is very high. To meet the required compressed air quality(2) appropriate filter element must be installed into filter housing. HPF process filter housing can be used in variety of applications. For applications not...

Open the catalog to page 7

Process and sterile filtration STAINLESS STEEL STERILE FILTERS 16 (10) bar 75 to 21.120 Nm3/h operating pressure volume flow rate side connections body connections operating temp. range SF stainless steel sterile filter housings have been specifically developed for removing of impurities from compressed air(1) system. To meet the required compressed air quality appropriate filter element must be installed into filter housing. SF filter housing is also designed for sterilisation. stainless steel 1.4301 other types on request Ra 0.78 SF process filter housing can be used in variety of...

Open the catalog to page 8

Process and sterile filtration STAINLESS STEEL STERILE FILTERS 5 µm stainless steel mesh operating temp. range 16 (12) bar 75 to 3.600 Nm3/h 1/4" to 3" threded up to DN200 flanged DIN11851 (milk pipe con.) up to 150 °C 25 µm stainless steel mesh 0,01 µm borosilicate micro fibres operating pressure 0,01 µm borosilicate micro fibres, volume flow rate side connections body connections DESCRIPTION SPF stainless steel sterile filter housings have been specifically developed for applications in process industry, where the risk for corrosion of compressed air(1) system components is very high. To...

Open the catalog to page 9

Process and sterile filtration STAINLESS STEEL AIR VENTING FILTER operating pressure volume flow rate body connections operating temp range stainless steel 1.4301 other types on request Ra 0.8 DESCRIPTION AV stainless steel filter housings have been developed to remove impurities from air(1) which is being feed or exhausted from tank during changing of liquid level. To meet the required air quality appropriate filter element (typically AVF filtration grade) must be installed into filter housing. AV filter housing is also designed for sterilisation. Before use, if needed for the application,...

Open the catalog to page 10

Process and sterile filtration Filtration grades Below are only the most common filtration grades for process applications are listed. For complete range of our products please check OMEGA AIR product catalogue or contact us for specific application. Solid particles high efficient removal of solid particles from compressed air Solid particles Solid particles high efficient removal of solid particles from process and culinary steam Solid Class particles high efficient removal of solid particles from compressed air high efficient removal of solid particles from compressed air Filter media...

Open the catalog to page 11All OMEGA AIR d.o.o. Ljubljana catalogs and technical brochures

-

Catalogue - Product overview

72 Pages

-

Screw compressors MA SD 2-3

2 Pages

-

MA SD 7,5-15 VS /BDK

2 Pages

-

Piston compressors - MEGA AIR

12 Pages

-

Container and Skid units

8 Pages

-

WFIF SERIES

2 Pages

-

WHFIT SERIES

2 Pages

-

MEGA TOOLS

12 Pages

-

MEGA AIR QUALITY OILS

8 Pages

-

CO2-R-DRY series

2 Pages

-

ACW series

1 Pages

-

ACA series

1 Pages

-

RDHP series

2 Pages

-

RDF

2 Pages

-

RDL series

2 Pages

-

RDP series

2 Pages

-

M-DRY series

2 Pages

-

HP-DRY series

2 Pages

-

R-DRY BVL series

2 Pages

-

R-DRY BP series

2 Pages

-

COM-DRY series

2 Pages

-

X-DRY series

2 Pages

-

A-DRY TAC

2 Pages

-

A-DRY BI+BM series

2 Pages

-

PV

2 Pages

-

AIR AND GAS Product overview

2 Pages

-

Compact oxygen generators

2 Pages

-

Compact nitrogen generators

2 Pages

-

SKID based solutions

2 Pages

-

Biogas plants

8 Pages

-

OCI

1 Pages

-

CKL-IHP series

2 Pages

-

SF series

2 Pages

-

WFIW series

2 Pages

-

MSS

2 Pages

-

MDH 400

1 Pages

-

CHI

1 Pages

-

VPG 60

1 Pages

-

FA - flange adapter

1 Pages

-

TD 400M series

1 Pages

-

AOK 50SS

1 Pages

-

EVD series

1 Pages

-

RC-DRY series

2 Pages

-

HPR-DRY series

2 Pages

-

TAC HP series

2 Pages

-

A-CAT series

2 Pages

-

SFH HP

2 Pages

-

TP PED series

2 Pages

-

TP ASME series

1 Pages

-

TP series

1 Pages

-

BS TOWER

1 Pages

-

PETRO-PACK

1 Pages

-

AWS

1 Pages

-

BS 12-3,5

1 Pages

-

AIRWATT series

2 Pages

-

B-AIR plus series

2 Pages

-

OWT

2 Pages

-

OWE/HWE

2 Pages

-

OWB

2 Pages

-

OBE SERIES

2 Pages

-

ECD-B series

2 Pages

-

MDHI 50

1 Pages

-

BF series

2 Pages

-

HPF series

2 Pages

-

AK- assembly kit for filters

1 Pages

-

IHP series

2 Pages

-

PF series

2 Pages

-

EPG 60

1 Pages

-

MDM40

1 Pages

-

OCI

1 Pages

-

AV series

2 Pages

-

SPF series

2 Pages

-

CS /CS SS series

2 Pages

-

SFH /SFH SS series

2 Pages

-

CKL-CHP series

2 Pages

-

MDM60

1 Pages

-

MDH

1 Pages

-

SORBEO Adsorbents

2 Pages