Website:

Nidec Graessner GmbH & Co. KG

Website:

Nidec Graessner GmbH & Co. KG

Catalog excerpts

Vibration analysis SmartCheck with integrated software Scope of delivery ■ SmartCheck device with integrated SmartWeb software ■ User manual SmartCheck and SmartWeb on CD-ROM ■ SmartUtility Light software with user manual on CD-ROM ■ Power cable for SmartCheck; 8-pin M12 socket on free cable end ■ Ethernet cable for SmartCheck; M12 plug on RJ45 ■ Input/output connection cables; 8-pin M12 plug on free cable end Why vibration analysis? ■ Information available regarding lifetime of the gearbox ■ Detection of damages on gearset or bearings, impacts, imbalance ■ Lifetime extension of the gearbox and prevention of sudden gearbox failures ■ Cost savings through prevention of unscheduled machine stops ■ Timely maintenance measures before gearbox failure: change of bearings, gearset and other effected parts, replacement gearbox Advantages Precise real time monitoring ■ Innovative vibration sensor with diagnosis technology ■ Intelligent process monitoring by recording different process parameters and correlation with vibration signals ■ Reliable alarm system with LED, PC and smart phone app (wireless LAN) Usability ■ Intuitive operation with the aid of the automatic adjustment of alarm thresholds thanks to selflearning mode (plug and play option) ■ LED error indication ■ Easy retrieval of measuring results the data can be retrieved directly at the SmartCheck (SmartWeb and SmartUtility Light) via standard web browser on PC Easy handling ■ Easy installation and less wiring ■ Compact size ■ Easy integration into control system and station

Open the catalog to page 1

Vibration analysis SmartCheck with integrated software Technical data Internal sensors ■ Acceleration sensor (piezo sensor) ■ Frequency range: 0,8 Hz – 10 kHz ■ Measurement range vibration: ± 50 g ■ Measurement range temperature: -20°C to +70°C (through tests up to +90°C without any problems, for higher temperatures usage of a small heatdismissive ceramic plate) Measurement ■ Acceleration ■ Speed and displacement by integration ■ Temperature ■ Process parameters (e.g. speed, load) ■ Diagnostic methods: time signal, envelope curve, spectrum and trend analysis, speed and frequency tracking...

Open the catalog to page 2All Nidec Graessner GmbH & Co. KG catalogs and technical brochures

-

KS TWINGEAR (en/de)

24 Pages

-

POWERGEAR MINIATURE (en/de)

12 Pages

-

NIDEC GUIDEDGEAR (en/de)

16 Pages

-

Product overview

12 Pages

-

DYNAGEAR

12 Pages

-

PowerGear (en/de)

36 Pages

-

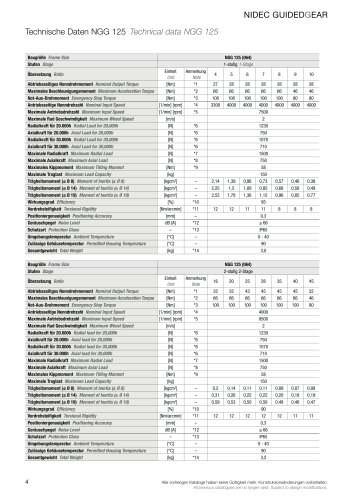

NGG (en/de)

9 Pages

-

DYNAGEAR ECO (en/de)

8 Pages

-

GEARFOX Software (en)

4 Pages

-

PlanetGear (en/de)

144 Pages

-

FLEXWAVE (en/de)

52 Pages

-

BEVELGEAR

8 Pages

-

TorusGear

4 Pages

-

MS-GRAESSNER ENGINEERING

8 Pages

-

PT1000

2 Pages