Website:

Nidec Graessner GmbH & Co. KG

Website:

Nidec Graessner GmbH & Co. KG

Catalog excerpts

MS-GRAESSNER ENGINEERING For everyone who expects more: special gearboxes from the specialist

Open the catalog to page 1

Driven by your requirements Our engineering and special manufacturing techniques have helped us become precision manufacturer of tooth systems and bevel gearboxes for almost 60 years, as well as specialist in special gearboxes. For us, individual solutions are standard. And instead of offering expertise that‘s confined to certain areas, like pure development for instance, we offer comprehensive know-how in all relevant areas – from the specifications and the first sketch up to the manufacturing of the zero series including intensive test operations. Our expertise also extends to a special...

Open the catalog to page 2

Four examples illustrating one principle: highly individual special gearboxes We offer a production-compatible design, specially adapted to the customer‘s applications, with innovatively designed drive sections, including planetary, spur gear, bevel and worm gear stages. We are driven by the desire to support our customers in the new development and optimisation of their tooth system designs through the innovative and sustainable development of special gearboxes. 72 mm High transmission miniature gearbox for applications in the automotive industry and in medical technology. Three-stage...

Open the catalog to page 3

We are only satisfied with the best solution, not with the first one that comes along. MS-Graessner has many years of experience as well as comprehensive know-how for special tasks, this is exactly what is required for the development of special gearboxes. From the individual drive section to the calculation of the complete drive train, a highly specialised, state of the art CAD-based developer software enables the accurate development and construction. The entire development process takes place in close cooperation with the customer. GEARFOX Software MS-Graessner‘s own, internetbased...

Open the catalog to page 4

Toothing calculation Gleason software optimises the design of individual components, like gear wheels for example: it covers tooth dimensions, gear tooth load data and meshing forces. It also deals with tooth contact analysis, the outline of the contact geometry as well as an extended calculation method of the tooth contact. The finite element analysis enables the calculation of the contact pattern under load and also provides information about the tooth base bending stress, surface pressure, the Wohler curve and much more. All designs and simulations are also carried out using special CAD...

Open the catalog to page 5

Short development times, optimal configuration and perfect results: it can only be our workflow management system. Feedback customer Development Order Our in-house, continually optimised MS-Graessner workflow management system guarantees an optimal engineering process: in an iterative, itself meaningfully repeating process with defined interfaces – closed loop (manufacturing loop) – all areas involved, including sales, development, production and customer, are integrated at an early stage and at all relevant points. Thus the optimal coordination of all departments involved is guaranteed at...

Open the catalog to page 6

Before it reaches you, we put your gearbox through hell! Practice is key. MS-Graessner‘s manufacturing expertise is the prerequisite for a production-ready gearbox, right from the start, because in addition to nearly 60 years’ experience making gearboxes, we also have the necessary skills and appropriate inspection and test procedures to check a newly developed gear through its paces. To paraphrase the old engineer‘s saying: confidence is good. Hardness tests are better. Our digitally-networked, CNC-controlled tool and measuring machines ensure highest quality as well as information about...

Open the catalog to page 7

DYNAGEAR The highly dynamic servo right angle gearbox DYNAGEAR Cc'n, The cost-effective servo right angle gearbox BEVEL GEAR Spiral, Hypoid and Zerol Bevel Gears The high performance bevel gearbox The bevel helical gearbox MS-GRAESSNER GmbH & Co. KG THE GEAR COMPANY Kuchenacker11 72135 Dettenhausen Tel.: +49 (0) 7157 123-0 E-Mail: mail@graessner.de www.graessner.de E-Mail: graessner@graessner.at www.graessner.at For more information on MS-GRAESSNER’s worldwide distribution network, please visit: www.graessner.com

Open the catalog to page 8All Nidec Graessner GmbH & Co. KG catalogs and technical brochures

-

KS TWINGEAR (en/de)

24 Pages

-

POWERGEAR MINIATURE (en/de)

12 Pages

-

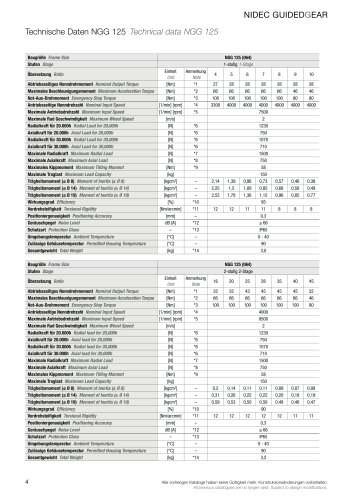

NIDEC GUIDEDGEAR (en/de)

16 Pages

-

Product overview

12 Pages

-

DYNAGEAR

12 Pages

-

PowerGear (en/de)

36 Pages

-

NGG (en/de)

9 Pages

-

DYNAGEAR ECO (en/de)

8 Pages

-

GEARFOX Software (en)

4 Pages

-

PlanetGear (en/de)

144 Pages

-

FLEXWAVE (en/de)

52 Pages

-

BEVELGEAR

8 Pages

-

TorusGear

4 Pages

-

SmartCheck

2 Pages

-

PT1000

2 Pages