Website:

Nidec Graessner GmbH & Co. KG

Website:

Nidec Graessner GmbH & Co. KG

Catalog excerpts

The highly dynamic servo-right angle gearbox

Open the catalog to page 1

Internal highlights The design of the DynaGear range has been influenced by extremely varied applications within many industry sectors. The DynaGear range has been developed with a highly dynamic servo drive solution in mind and therefore benefits from many advantages. Weight efficient one-piece Aluminium housing ensures highest stability n Right angle gearbox, single-stage, ratios from High-quality taper roller bearings absorb axial and radial loads guaranteeing a long service life 3 : 1 to 15 : 1, two-stage up to 100 : 1, higher ratios on request. n The compact and rigid design ensures...

Open the catalog to page 2

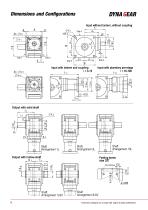

External highlights The DynaGear realises the theme “Motor – Coupling – Gearbox – Mounting” in a unique way. n The DynaGear fits all current servo motors by way of flanges and couplings to suit. n Torsional vibration can be adjusted via the coupling stiffness. n The gearbox dimensions are identical for all ratios. Solid shaft version with continuous shaft, coupling and input flange Compact and weight efficient aluminium housing Easy mounting without additional parts Hollow shaft version with coupling and input flange Couplings and adaptor flanges to suit all motors Subsequent motor type...

Open the catalog to page 3

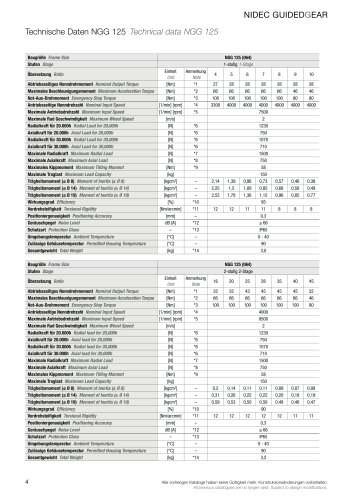

Performance table/Technical data DynaGear Size Ratio Output torque Nominal torque Maximum acceleration Emergency stop torque Maximum input speed Nominal input speed i = 3/4/5 Nominal input speed i = 6/8/10 Standard backlash Reduced backlash Backlash stiffness at the output Radial force Axial force Efficiency rating at full load -1 Noise level (n1=3000 min ) Weight approx. Size Ratio Output torque Nominal torque Maximum acceleration Emergency stop torque Maximum input speed Nominal input speed Standard backlash Reduced backlash Backlash stiffness at the output Radial force Axial force...

Open the catalog to page 4

Performance table/Technical data Mass moment of inertia I1 related to input [kgcm²] for shaft arrangement WA 1 DynaGear Ratio i 3:1 4:1 5:1 6:1 8:1 10:1 12:1 15:1 Values without coupling Symbols and units Maximum motor acceleration torque Nominal output torque Maximum output acceleration EMERGENCY STOP output torque Maximum input speed Nominal input speed Output backlash Torsional output stiffness Radial input force Radial output force Axial input force Axial output force Efficiency at full load Running noise Weight Mass moment of inertia Service life Run time Duty cycle Ambient temperature...

Open the catalog to page 5

All previous catalogues are no longer valid. Subject to design modifications.

Open the catalog to page 6

Pitch circle diameter, centering diameter, thread and centering depth according to the relevant motor data sheet Input with planetary pre-stage for motor shaft and input flange Size D55HR D75HR D90HR D115HR D130HR D140HR D160HR D190HR Square u, the pitch circle diameter Ø v with threads s and the centering diameter Ø w with length m are motor dependent. Please contact us! Standard square for relevant motor type According to D DIN 332 Extended shaft for the shrink disk (e.g. Stüwe – Type HSD 22) Delivery with shrink disk on request www.graessner.de All previous catalogues are no longer...

Open the catalog to page 7

Output with robot flange according to EN ISO 9409-1 and hollow shaft Ø d2 h8 All previous catalogues are no longer va

Open the catalog to page 8

For entire DynaGear range Operation mode S5 duty cycle (DC) < 60 % and run time (RT) < 20 min Maximum existing motor acceleration torque T1BMot [Nm] Calculate the maximum existing acceleration torque at the gearbox output T2Bmax exist. = T1BMot x i [Nm] Compare the maximum existing acceleration torque at the gearbox output with the permissible acceleration torque at the gearbox output ≤ T2Bmax exist. ≤ T2Bperm. x k Existing average speed n1exist. ≤ nominal speed n1N Valid for an average torque of 30 % of the permissible output torque T2N Compare the motor dimensional details such as flange...

Open the catalog to page 9

Technical service and maintenance DynaGear and DynaGear Economy Gearboxes DYNAGEAR gearboxes are supplied ready lubricated for life with a high-quality synthetic oil to CLP DIN 51 517, ISO VG-Class 150 (DIN 51 519). They are therefore maintenance free. We recommend that for continuous operation close to the thermal performance limit, regular leak controls are undertaken on the shaft seals. After approx 15.000 operating hours, it is advisable to change the oil. Please request instructions which also include advice on lubricants and quantity. Service kits of wear and tear parts with full...

Open the catalog to page 10

Ordering Example 1. Gearbox range = DynaGear D D..HR = DynaGear High Ratio 2. Size 3. Ratio 4. Configuration 5. Additional data See page 6 + 8 • nput speeds I Maximum application speed • Options – if required • Customised design – if required Please include the relevant motor data sheet. Please note that All information contained in this catalogue is provided without guarantee and is not binding. In particular, dimensions and values only provide guidance. Any exact, specific requirements must be agreed with us. Specifications and features listed in the catalogue are subject to a written...

Open the catalog to page 11

DYNA GEAR POWER GEAR Standard range of products and custom-made versions Module ms from 0.5 to 12 Diameters up to 410 mm Shaft angles from 10° to 170° More than 60 years of experience In-house gearing calculations We manufacture to your drawing or advise you of possible alternatives Milled or ground gear tooth cutting The highly dynamic servo right angle gearbox The high performance bevel gearbox I I I I I I I DYNA GEAR Economy The cost-effective servo right angle gearbox I DESIGN GEAR Hypoid gearing High input speeds at medium to high torques Ratios single-stage i = 3:1 to 30:1 Ratios,...

Open the catalog to page 12All Nidec Graessner GmbH & Co. KG catalogs and technical brochures

-

KS TWINGEAR (en/de)

24 Pages

-

POWERGEAR MINIATURE (en/de)

12 Pages

-

NIDEC GUIDEDGEAR (en/de)

16 Pages

-

Product overview

12 Pages

-

PowerGear (en/de)

36 Pages

-

NGG (en/de)

9 Pages

-

DYNAGEAR ECO (en/de)

8 Pages

-

GEARFOX Software (en)

4 Pages

-

PlanetGear (en/de)

144 Pages

-

FLEXWAVE (en/de)

52 Pages

-

BEVELGEAR

8 Pages

-

TorusGear

4 Pages

-

MS-GRAESSNER ENGINEERING

8 Pages

-

SmartCheck

2 Pages

-

PT1000

2 Pages