Website:

NIASA, NEFF Y ASOCIADOS, S.A.

Website:

NIASA, NEFF Y ASOCIADOS, S.A.

Catalog excerpts

“THERE IS A DRIVING FORCE MORE POWERFUL THAN STEAM, ELECTRICITY AND ATOMIC ENERGY: THE WILL.” ALBERT EINSTEIN Physicist Niasa actuators in the Tonopah thermo-solar plant, Nevada, USA.

Open the catalog to page 3

SCREW JACKS introduction NIASA N/W/R Series screw jacks are a combination of a screw with a gearbox. There are three types of configurations that can be adapted to different requirements: …… N: The screw moves when the gearbox input shaft (worm shaft end) is activated. It includes a rounded screw protection tube on the back. …… W: The screw engages, as in configuration N but with the difference that the back protective tube is square section, which means it can be an anti-rotating screw. …… R: The screw does not move with the driving of the worm shaft, it only turns; it is the corresponding...

Open the catalog to page 5

SCREW JACKS APPLICATIONS Machine TILTING system Set of two M4-N screw jacks made up of a three-phase motor drive system and joined together with a GX universal joint shaft. Tilt on the top of the gearbox with a ZKM joint adapter, SB tip supports, GKB series double clevis rod, FB protective bellow, inductive sensor and electro-magnetic brake. Manual positioning system. 22 Set of three M2-N screw jacks made up of a manual drive system with a VE series wheel and joined together with GX universal joint shafts. LCM-series mounting feet underneath the box, GKB series double clevis rod, manual...

Open the catalog to page 7

Photovoltaic installation M5-W screw jack with IPX protection for outdoor weather made up of a three-phase motor drive system, tilt underneath the gearbox with a ZKM joint adapter, clevis rod with GIR series ball joint on the screw, EPDM special protection bellow and inductive sensor. Platform elevation system. Set of four M5-N screw jacks made up of a three-phase motor drive system and joined together with EZ universal joint shafts and bevel gearboxes. LCM-series mounting feet underneath the box, BPS flange fastening on the screw, FB series protective bellow and PR series worm shaft...

Open the catalog to page 8

SCREW JACKS On all the sizes there are trapezoidal and screw drive options (see chapter 07 for further information), as well as normal speed (S) and reduced speed (H) gearboxes. The screw moves. page 28 page 30 page 32 page 34 screw. page 28 page 30 page 32 page 34 The nut moves. page 29 page 31 page 33 page 35 In addition to the standard range of screw jacks, NIASA can specifically develop the unit that best meets your application requirements. Contact NIASA.

Open the catalog to page 9

SCREW JACKS GENERAL PRODUCT OVERVIEW 11 17 Flange with ZKV 90º bolts 19 FCM mechanical limit switch 20 FCI inductive limit switch 07 Wheel with VE grip 15 Flange with ZKM bolts 08 PR worm gear protector 16 Flanges with ZKH bearings

Open the catalog to page 11

18 Flange with ZKM bolts 11 Flange with BPR bearing 19 Flanges with ZKH bearings 20 Flange with ZKV 90º bolts 22 Flange with KAR bolts 07 Wheel with VE grip 08 PR worm gear protector

Open the catalog to page 12

The screw sizes indicated correspond to the basic configurations. Other configurations may be ordered (size, type, etc.) on request. Ø30 (Ø48) M5x8 Prof. On both sides Greasing mechanism Screw diameter and pitch (mm) Maximum axial strength (kN) M8x13 Prof. On both sides NOTES: - The values in brackets correspond to the versions with KG screw. * Version W. Travel (mm/revol. input) F (kN), load to move in dynamic Approx. weight each 100mm of stroke (kg) … Power required: PD (kW) = 0.157 x MD (Nm). … All the data in the table correspond to an input speed of 1,500 rpm. For other speeds, please...

Open the catalog to page 13

The screw sizes indicated correspond to the basic configurations. Other configurations may be ordered (size, type, etc.) on request. Ø12j6 15 Greasing mechanism DIN71412 Inclined 45° MT508 = M5x8 Prof. On both sides Screw diameter and pitch (mm) Maximum axial strength (kN M8x13 Prof. On both sides Travel (mm/revol. input) F (kN), load to move in dynamic Approx. weight each 100mm of stroke (kg) … Power required: PD (kW) = 0.157x MD (Nm). … All the data in the table correspond to an input speed of 1,500 rpm. For other speeds, please see the calculation chapter (page 47). ... Ensure that the...

Open the catalog to page 14

The screw sizes indicated correspond to the basic configurations. Other configurations may be ordered (size, type, etc.) on request. M6x9 Prof. On both sides Screw diameter and pitch (mm) NOTES: - The values in brackets correspond to the versions with KG screw. * Version W. Maximum axial strength (kN) M8x15 Prof. On both sides Travel (mm/revol. input) F (kN), load to move in dynamic Approx. weight each 100mm of stroke (kg) … Power required: PD (kW) = 0.157x MD (Nm). … All the data in the table correspond to an input speed of 1,500 rpm. For other speeds, please see the calculation chapter...

Open the catalog to page 15

The screw sizes indicated correspond to the basic configurations. Other configurations may be ordered (size, type, etc.) on request. Ø15j6 Greasing mechanism DIN71412 Inclined 45° MT508 = M6x9 Prof. On both sides Screw diameter and pitch (mm) Maximum axial strength (kN) Travel (mm/revol. input) F (kN), load to move in dynamic Approx. weight each 100mm of stroke (kg) … Power required: PD (kW) = 0.157x MD (Nm). … All the data in the table correspond to an input speed of 1,500 rpm. For other speeds, please see the calculation chapter (page 47). ... Ensure that the dynamic load of the...

Open the catalog to page 16

The screw sizes indicated correspond to the basic configurations. Other configurations may be ordered (size, type, etc.) on request. M8x10 Prof. On both sides Greasing mechanism DIN71412 Screw diameter and pitch (mm) Maximum axial strength (kN) M10x14 Prof. On both sides Travel (mm/revol. input) F (kN), load to move in dynamic Approx. weight each 100mm of stroke (kg) … Power required: PD (kW) = 0.157x MD (Nm). … All the data in the table correspond to an input speed of 1,500 rpm. For other speeds, please see the calculation chapter (page 48). ... Ensure that the dynamic load of the...

Open the catalog to page 17All NIASA catalogs and technical brochures

-

Bevel Gearboxes

24 Pages

-

Ball Screw Drives

36 Pages

-

Screw Supports

24 Pages

-

LINEAR TABLES

19 Pages

-

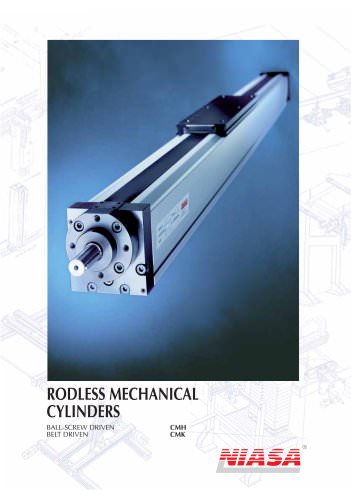

RODLESS MECHANICAL CYLINDERS

16 Pages