Website:

Möllers

Website:

Möllers

Group: MöllerGroup

Catalog excerpts

NORTH AMERICA Type PHS – Palletizer with Integrated Automatic Transverse Stretch Hooder MASCHINENFABRIK MÖLLERS

Open the catalog to page 1

Palletizing with Maximum Precision

Open the catalog to page 2

Transverse Stretch Hood Technology for Optimal Load Security

Open the catalog to page 3

Palletizing & Stretching: Innovation by Combination Palletizing Technology of highest quality combined with our extremely efficient Transverse Stretch Hood Technology – the concept of the 2 in 1 Series. Using a minimum of space, Möllers Group combines two well-established and high-end technologies, creating a true innovation in the field of palletizing and load security. Applying the know-how and experience of both technologies, Möllers Group has developed a two-component system that meets the highest demands: The floor-leveled automatic palletizer stacks packaged goods stably and securely...

Open the catalog to page 4

01. Low Bag Infeed | The low bag infeed allows to overview the complete work process. 03. Layer Palletizing | The layer is transported to the pallet and positioned on top of it. 02. Gentle Bag Formation | Layers of packed goods are gently positioned according to the individually specified layer pattern. The Road to Secure Loads – The Essential Steps Combining the best features of two worlds: It simply requires very few completely automated steps and the PHS palletizes packaged goods and secures the load ready for dispatch. Packaged goods of all sorts are no problem for the PHS: the new...

Open the catalog to page 5

04. Layer Formation | The packaged goods are formed and positioned lengthand crosswise. 05. Minimum Drop-Height | The packaged goods are positioned, dropping from a minimal height. 06. Layer Pressing | The layer is leveled by surface pressure. Layer formation and customized positioning of the packaged goods are crucial strengths of this new system. Having the low infeed at eye-level, the complete work process can be overviewed the whole time. A further advantage: The pallet does not move during the stacking procedure. For the formation of a new stack the PHS takes every newly formed layer...

Open the catalog to page 6

07. Film Feed & Film Opening | Four suction pads open the side-gusseted tubular film. 08. Simple Film Intake | Tightly interlocked stretch fingers pick up the film precisely without failure. 09. Hood Formation | Reefing of the size-adjusted hood. Securely Packed for Transport and Storage and storage. The PHS is able to operate with all commercially available film strengths from standard to ultra stretch. The side-gusseted tubular film is fed into the machine from above, spread apart by four suction pads in order for the stretching fingers to position themselves. The tight interlocking of...

Open the catalog to page 7

12. Film Finish | Underwrap or high-bay-rack-stretch. 10. Film Stretch | Stretching of film according to the required pallet format. 11. Film Wrapping | High reset forces for a secure load on the pallet. maximum precision, without requiring any further mechanical systems. Pallets of all formats can be secured with stretch film without having to change the tubular film. The PHS simply stretches the film to the format of the pallet and its load. Within seconds, the load is wrapped, and the high reset forces ensure that the load is connected with the pallet in a most long-lasting and secure...

Open the catalog to page 8

PHS | High-end technology – Extensive experience in the field of mechanical engineering combined with high standard German quality manufacturing of all parts ensure the most advanced technological progress of the PHS. Full Flexibility within a Minimum of Space Fulfilling highest demands is no problem for the PHS. High flexibility is its greatest feature. The PHS offers high-end technology within a minimum of space without making any compromises. Flexible applicability comes first. It supports palletizing with and without supplementary flat film for protection against humidity as well as...

Open the catalog to page 9

Operation 2 in 1 Series: Type PHS 01 | Infeed for empty pallets 02 | Flat film application 03 | Low infeed of the packaged goods 04 | Customized palletizing 05 | Load securing in the same location 06 | Pallets ready for transport 07 | Easy operation of control panel 08 | Separate securing including contour control and pallet alignment (Various load carriers possible: Octabin, FIBC, etc.) Maximum Technological Performance and Sustainability Solutions for the long-term application: The planning and construction of the PHS set new standards regarding sustainability. An innovation only effects...

Open the catalog to page 10

Outstanding Qualities for Every Purpose As a leading engineering enterprise, innovation is a signature feature of the Möllers Group. Choose the combination of two high-end technologies and give your goods a headstart in palletizing and load securing processes: - Palletizing and load securing in the same location - The whole process within a minimum of space - The complete production process is easily accessible from start to finish - High flexibility in processing packaged goods, pallets and film types - Optimal operating sequence for low energy consumption - High efficiency - Easy...

Open the catalog to page 11

Technical Description 2 in 1 Series: Type PHS | At one glance: The PHS offers maximum performance in a minimum format, making it an indispensable manufacturing system. Technical Data Technical Data: PE side-gusseted tubular film Load width Load length Load height Film strength Film type

Open the catalog to page 12

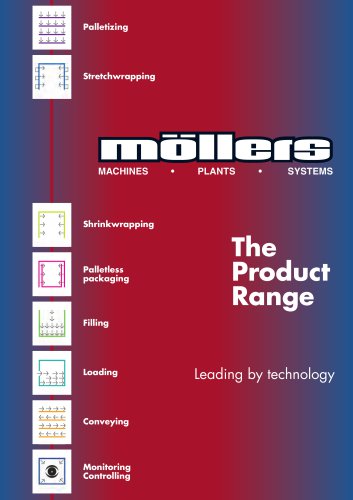

2in1 Series Möllers Group – Competence by Experience Conveying, Filling, Palletizing, Wrapping, Loading and Warehousing – our machines, equipment and systems set benchmarks for the manufacturing industry. For decades the Möllers Group, with the combined strength of several manufacturing plants on different sites around the world, has stood for competence and innovation in machine engineering. With us, the customer takes center stage: More than 500 highly qualified staff members advise and design, manufacture and install, maintain and improve, for the highest quality and comprehensive...

Open the catalog to page 13All Möllers catalogs and technical brochures

-

HSB-2600

4 Pages

-

2in1 Series

13 Pages

-

HSA-Vario

16 Pages

-

Seminare

16 Pages

-

PLS-C

16 Pages

-

PSH-1 / PSH-2 / PSH-Vario

12 Pages

-

Automatic stretch hooder

16 Pages

-

Bag Loading Systems

11 Pages

-

Full Line. High Quality.

32 Pages

-

FIBC Filling Systems

6 Pages

-

Valve-Bag Filling Systems

8 Pages

-

Palletizing Systems

16 Pages

-

Palletless Packaging Lines

16 Pages

-

R&D Center

9 Pages