Website:

Metal Textiles Europe

Website:

Metal Textiles Europe

Group: United Capital

Catalog excerpts

TECHNICAL BULLETIN NUMBER 101 SPHERICAL JOINT SYSTEM CUSTOM-ENGINEERED SOLUTIONS IN KNITTED WIRE MESH Metex Knitted Wire Mesh Products Solve Problems Cost Effectively Metex knitted wire mesh is manufactured from an “endless” wire that is formed into loops and subsequently networked, providing elasticity and resilience not found with woven wire or powdered metal products. The diversity and versatility of wire mesh enables Metex to produce products for a wide variety of applications, including: • Seals • Heat Wicks • Air Gap Rings • Breathers • Noise Attenuators • Filters • Coalescers • Mufflers • Shock Absorbers • Gaskets • Air Filters • Protective Coverings • Heat Shields • Electronic Shielding • Exhaust Seals • Navin Rings • Ball Joint Seal • Catalytic Converter • Catalytic Converter Systems End Rings Support Mesh • Flame Arrestors For forty years, Metex design, development, and manufacturing engineers have been producing engineered components that take maximum advantage of the unique characteristics and robust nature of knitted wire mesh. Its interlocked looped structure, which offers excellent resiliency, memory— even when subjected to high temperatures as well as high-tensile or compressive stress—and strength, make knitted wire the ideal choice in materials when both performance and cost are paramount. Metex products now meet a wide range of critical needs—from providing flexible, yet durable, seals and joints to noise attenuation, thermal insulation, and filtration—in some of the most demanding industrial applications and environments. Our Spherical Joint System continues a longstanding Metex tradition of integrating the right designs, materials, and manufacturing methods to meet customer needs for optimal performance at lowest possible cost. Complete in-house design, R&D, and test facilities Metex Corporation 970 New Durham Road Edison, New Jersey 08818 Phone: 732-287-0800 1-800-222-0969 Fax: 732-287-8546 E-mail: sales@metexcorp.com Metex Mexico No. 30 Del Centro Industrial Limon Los Pinos En Av. Ferrocarril KM 14.5 En El Fracc. Los Pinos Tijuana, Baja California Mexico Phone: 011-52-66-89-74-34 Fax: 011-52-66-89-74-53 Flexibility in manufacturing for JIT requirements A New, Low-Cost, Spherical Joint Design for Automotive Exhaust Systems The Metex Spherical Joint System combines breakthrough innovation and global best practices of the classic spring-loaded ball joint in a turnkey system to assure consistent superior performance for the life of the vehicle. Using a system approach, the proven durable ball joint technology has been optimized to provide near “zero leak” performance at a fraction of the cost of bellowsbased systems, while meeting the stringent durability and customer satisfaction needs of major automotive manufacturers worldwide. The self-supporting design can support the weight of the exhaust system in either the vertical or horizontal direction, eliminating need for additional hangers. In addition, the system displays stable, consistent, dynamic behavior throughout the life of the vehicle. The Metex spherical-loaded joint system offers the following performance characteristics: O • Operating temperatures up to 700 C (flange surface) • Less than 1.0 standard liters per minute leakage at pressures up to 34kPa when new • Less than 2.0 standard liters per minute leakage at pressures up to 34kPa after vehicle durability tests • Pipe outside diameters from 38 mm to 76 mm The Metex spherical joint system is a complete “turnkey” spring-loaded ball joint for use in the exhaust systems of internal combustion engines. The system was developed to provide a joint with “near-zero” leakage performance in automotive exhaust systems, while acting as a: • Decoupling point to isolate the vibrations of the engine from the remainder of the exhaust system and the passenger compartment. This is extremely important in automobiles where any reduction in noise, vibration, and harshness (NVH) will improve ride quality. • Pivot point to stop the exhaust system from moving when the engine exhibits large amplitude rolling motion. This is most important in front wheel drive (FWD) vehicles with transverse mounted engines. In these cases, the roll axis of the engine is perpendicular to the axis of the exhaust system. With no pivot point, the exhaust will slam into the vehicle underbody, or the ground, when the engine rolls upon gear changes and acceleration/deceleration. US Patent 5,683,119 and Foreign Patents

Open the catalog to page 1

SPHERICAL JOINT SYSTEM TECHNICAL BULLETIN PRODUCT BENEFITS Sealing Ability—The unique “turnkey” system design maximizes sealing ability and virtually eliminates leakage. Competitive Price— Lower cost alternative to flex couplings. Compact Size—Easier packaging. Minimizes heat loss. Self Supporting—Can support weight of exhaust systems in horizontal or vertical direction. Eliminates extra support hangers. Torsional Degree of Freedom—Capable of accommodating relative twist between upstream and downstream portions of the joint. Stable, Consistent Performance—Unlike flex couplings, whose...

Open the catalog to page 2

SPHERICAL JOINT SYSTEM TECHNICAL BULLETIN PRODUCT BENEFITS Sealing Ability—The unique “turnkey” system design maximizes sealing ability and virtually eliminates leakage. Competitive Price— Lower cost alternative to flex couplings. Compact Size—Easier packaging. Minimizes heat loss. Self Supporting—Can support weight of exhaust systems in horizontal or vertical direction. Eliminates extra support hangers. Torsional Degree of Freedom—Capable of accommodating relative twist between upstream and downstream portions of the joint. Stable, Consistent Performance—Unlike flex couplings, whose...

Open the catalog to page 3

TECHNICAL BULLETIN NUMBER 101 SPHERICAL JOINT SYSTEM CUSTOM-ENGINEERED SOLUTIONS IN KNITTED WIRE MESH Metex Knitted Wire Mesh Products Solve Problems Cost Effectively Metex knitted wire mesh is manufactured from an “endless” wire that is formed into loops and subsequently networked, providing elasticity and resilience not found with woven wire or powdered metal products. The diversity and versatility of wire mesh enables Metex to produce products for a wide variety of applications, including: • Seals • Heat Wicks • Air Gap Rings • Breathers • Noise Attenuators • Filters • Coalescers •...

Open the catalog to page 4All Metal Textiles Europe catalogs and technical brochures

-

Air & Liquid Filters

4 Pages

-

Crankcase Ventilation

4 Pages

-

Ring Gasket with Heat Shield

2 Pages

-

Shielding Tape

2 Pages

-

EMI Vent Panels

4 Pages

-

Conductive Silicone Adhesive

2 Pages

-

Blanket Mesh

4 Pages

-

Copper Gauze

2 Pages

Archived catalogs

-

Fabric Over Foam

8 Pages

-

Wire Mesh Separators

2 Pages

-

Coated Catalysts

2 Pages

-

Shock & Vibration

4 Pages

-

Noise Suppression

4 Pages

-

Air and Liquid Filters

4 Pages

-

Gaskets and Seals

4 Pages

-

Static Flange Gaskets

4 Pages

-

Shielded Windows

2 Pages

-

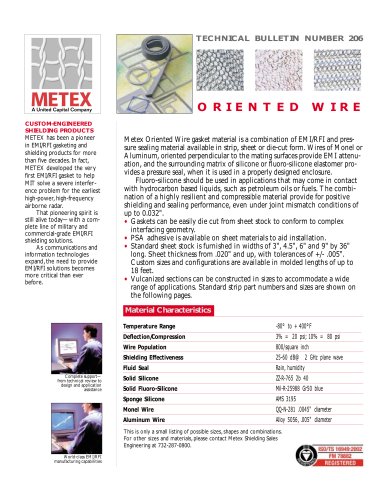

Oriented Wire

4 Pages

-

Conductive Fabric

2 Pages

-

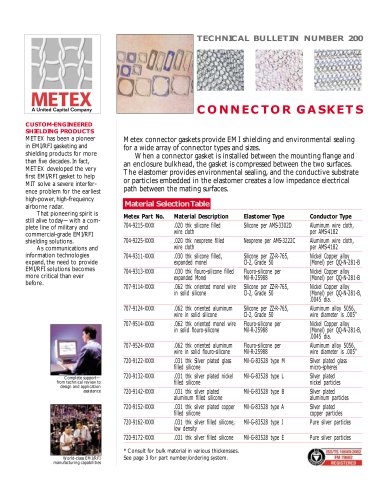

Connector Gaskets

4 Pages

-

Braided Sleeving/Rope

2 Pages

-

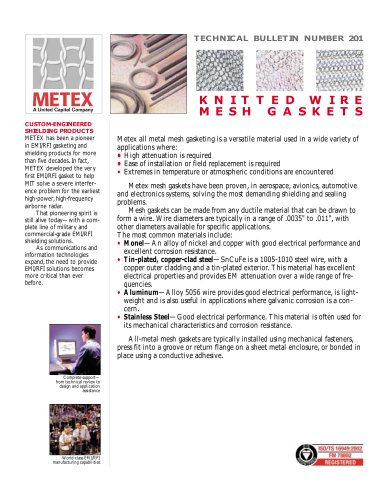

Wire Mesh Gaskets

4 Pages