Website:

Materials Research Furnaces

Website:

Materials Research Furnaces

Catalog excerpts

Today’s Furnaces for Tomorrow’s Technologies. High Temperature Controlled Atmosphere Furnaces FULL PRODUCT LINE CUSTOM DESIGNS FIELD SERVICE SPARE PARTS

Open the catalog to page 1

TODAY’S FURNACES FOR TOMORROW’S TECHNOLOGIES Materials Research Furnaces, Inc. MRF, Inc. Suncook Business Park 65 Pinewood Road Allenstown, NH 03275 Phone 603.485.2394 • Fax 603.485.2395 Web: www.mrf-furnace

Open the catalog to page 3

hank you for your interest in Materials Research Furnaces, Inc. This catalog contains a cross section of our products that we have designed and built over the years, categorized to give an overview of our capabilities. Please keep in mind that even though we have standard products, we are custom furnace designers; if you cannot find what you are looking for, please contact us to discuss your furnace requirements. We often design furnace systems for specific applications, however many furnaces can be used or adapted for many high temperature controlled environment process applications. We...

Open the catalog to page 9

COMPANY PROFILE About Us High Temperature Furnaces aterials Research Furnaces, Inc. was founded in 1990 by a group of highly trained and experienced engineers and technical personnel to answer the challenge of the research and development community to produce the finest high temperature vacuum and controlled atmosphere furnaces in the industry. Over the years we’ve worked with our customers to design furnace systems that have enabled them to meet the ever increasing demands of advanced technology environments. Our customers include colleges, universities, government laboratories and private...

Open the catalog to page 11

This page is intentionally left blank.

Open the catalog to page 12

PRODUCT OVERVIEW Product Overview or simplicity, MRF Products have been divided into categories based on the geometry of the furnace chambers or based on major functional differences. As many of the furnaces in the different categories can be used for similar applications, potential customers are encouraged to look at the different sections to weigh the benefits and drawbacks of using a certain type of furnace for their specific application. In some instances the type of furnace that is chosen depends on preference or process details unknown to us, rather than functionality or cost alone....

Open the catalog to page 13

This page is intentionally left blank.

Open the catalog to page 14

ARC MELT/ BELL JAR FURNACES Arc Melt/ Bell Jar Furnaces Arc melt furnaces provide a cost saving alternative to resistance or inductance heating furnaces for many applications. Rather than resistance heaters or induction coils, an electric arc is used to heat up and/or melt parts. Our Arc Melt Furnaces can instantly reach temperatures over 3500C, and will cool down to room temperature in minutes. Our systems are simple to operate, are extremely reliable and have a low acquisition and operation cost. There are a multitude of available options such as load locks, splat rod, rotating hearth,...

Open the catalog to page 15

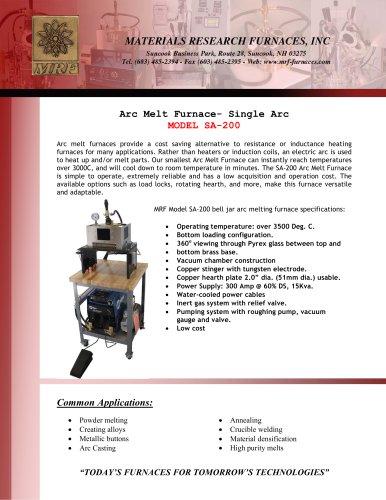

Single Arc Melt Model SA-200 The SA-200 is our smallest arc melt furnace and has a 2” copper hearth with crucible which holds customer material. All our systems come as a complete turn-key system and can reach temperatures above 3500C instantly. Custom hearth cavities to produce specific melt shapes are available at no extra cost when specified at time of order. • • • • • • • • • • • Operating temperature: over 3500°C. (6332F) Bottom loading configuration. 360o viewing through Pyrex glass between top and Bottom brass base. Vacuum chamber construction. Copper stinger with tungsten electrode....

Open the catalog to page 16

Tri Arc Melt Model TA-200 The TA-200 arc melt furnace is identical to our Model SA-200, with the exception that it is equipped with three stingers instead of one. Three arcs allow for a larger and more homogeneous melt and makes it suitable for crystal growing (optional). Operating temperature over 3500 Deg. C. Bottom loading configuration. 360o viewing through Pyrex glass between top and bottom brass base. Vacuum chamber construction Three copper stingers with tungsten electrode. Copper hearth plate 2.0” dia. (51mm dia.). Power supply: 400 Amp @ 60% DS, 35Kva. Water cooled Inert gas system...

Open the catalog to page 17

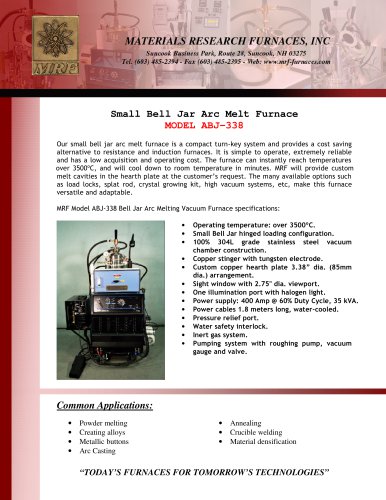

Bell Jar ABJ-338 The ABJ-338 is our small bell jar arc melt furnace. Instead of being loaded from the bottom as in our SA-200 or TA-200, the chamber is hinged backwards to allow easier access and loading of the material. The 3.38“ (86mm) hearth plate also allows for multiple crucibles vs the single crucible of the SA/TA-200. • • • • • • • • • • • • Operating temperature over 3500ºC. Small Bell Jar hinged loading configuration. 100% 304L grade stainless steel vacuum chamber. Copper stinger with tungsten electrode. Custom copper hearth plate 3.38” dia. (86mm dia.) free of charge with order....

Open the catalog to page 18

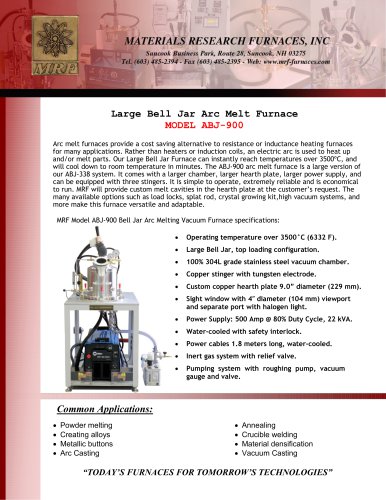

Bell Jar ABJ-900 The ABJ-900 arc melt furnace is a large version of our ABJ-338 system. It comes with a larger chamber, larger 9” (229mm) hearth plate, larger power supply, and can be equipped with three stingers and crystal grower. • • • • • • • • • • Operating temperature over 3500ºC. Large Bell Jar hinged-loading configuration. 100% 304L grade stainless steel vacuum chamber. Copper stinger with tungsten electrode. Custom copper hearth plate 9.0” dia. (230mm dia.). Sight window with 4" dia. view port. and separate port with halogen light. Power Supply: 650 Amp @ 60% Duty Cycle, 55 kVA....

Open the catalog to page 19

ARC MELT/ BELL JAR OPTIONS Arc Melt / Bell Jar Options To meet specific customer needs and increase the application range of our Arc Melt Furnaces, MRF has a large variety of options and accessories available. Many options can be combined to create a diverse Arc melt system. Option Custom Cavities MRF provides specific shapes and dimensions for sample/melt cavities in the hearth plate. This is provided at no additional cost with placement of order. Equips our systems with a high precision motion system and crucible for Czochralski crystal growing. High Vacuum System Diffusion pump or Turbo...

Open the catalog to page 20All Materials Research Furnaces catalogs and technical brochures

-

Arc Melt Furnace SA-200

4 Pages

-

Arc Melt Furnace ABJ-900

4 Pages

-

Arc Melt Furnace ABJ-338

4 Pages

-

Arc Melt Furnace TA-200

4 Pages