Website:

Materials Research Furnaces

Website:

Materials Research Furnaces

Catalog excerpts

Arc Melt Furnace- Tri Arc MODEL TA-200 The TA-200 arc melt furnace is identical to our Model SA-200, with the exception that it is equipped with three stingers instead of one. Triple arcs allow a larger and more homogeneous melt. This Arc Melt Furnace can instantly reach temperatures over 3000 deg. C, and will cool down to room temperature in minutes. It is simple to operate, extremely reliable and has a low acquisition and operation cost. The available options such as load locks, splat rod, rotating hearth, crystal growing kit, oxygen monitor and more, make this furnace versatile and adaptable. MRF Model TA-200 specifications: Operating temperature: over 3000 Deg. C. Bottom loading configuration. 360o viewing through Pyrex glass between top and bottom brass base. Vacuum chamber construction Three copper stingers with tungsten electrode. Copper hearth plate 2.0” dia. (51mm dia.). Power supply: 350 Amp @ 60% DS, 14Kva. Water-cooled power cables Inert gas system with relief valve. Pumping System with roughing pump, vacuum gauge and valve. Low cost Powder melting Creating alloys Metallic buttons Arc Casting Annealing Crucible welding Material densification High purity melts

Open the catalog to page 1

Major System Components: 1. Furnace Chamber: The chamber consists of a brass bottom and top with a Pyrex viewing tube. The chamber top and base are water-cooled to maintain a chamber temperature below 50C (120F) during normal use. The chamber is rated for vacuum to 10-2 Torr (Mbar) The chamber top houses the stinger assemblies. Access to the furnace for loading and unloading is through the bottom cover. Clamps are provided to isolate and seal the bottom cover Vacuum and gas port is supplied. Three eye protection shields are provided, allowing arc viewing from three sides....

Open the catalog to page 2

3. Hearth Plate: ■ The hearth plate (anode) is copper and has an o-ring vacuum seal. ■ Cavity dimensions: 2.0" (51 mm) diameter ■ Custom cavities in the bottom hearth plate are provided at no charge ■ An optional rotating hearth is available (1 - 60RPM) 4. Inert gas system: ■ This furnace system was designed to operate in Argon, Nitrogen, or non-flammable forming gas. ■ A pump-out followed by a gas backfill provides a fast way to remove all oxygen from the chamber. ■ The standard positive pressure for operation is .14 kg/cm sq (2PS1G). ■ A relief valve and a 30/30 compound gauge (30 PSIG x...

Open the catalog to page 3

10. Documentation: Two sets of Installation and Operating instructions, component manuals and assembly drawings are included with the equipment - one hard copy, one copy on CD. 11. Options & Accessories Rotating Hearth Crystal Growing Kit High Vacuum System • Load Lock • • Splat Rod • • Oxygen Monitor • Utilities ■ Electricity: 15 Kva, 230/240/380/460V, Three phase, 50-60 Hz. ■ Waiter: 7.5 LPM flow, inlet temperature 68F (20oC) at 40PSI (3.5 kg/cm2) ■ Gas: Argon, Nitrogen or non-flammable forming gas, plant or bottle supply 40PSI (3.5 kg/cm2). “TODAY'S FURNACES FOR...

Open the catalog to page 4All Materials Research Furnaces catalogs and technical brochures

-

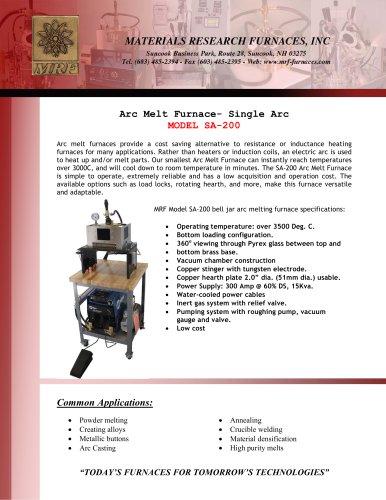

Arc Melt Furnace SA-200

4 Pages

-

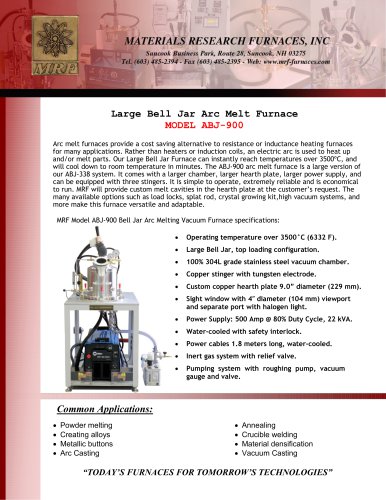

Arc Melt Furnace ABJ-900

4 Pages

-

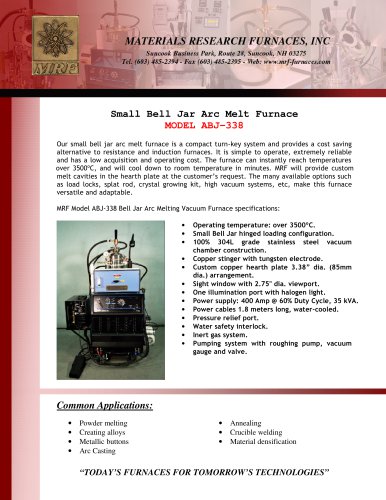

Arc Melt Furnace ABJ-338

4 Pages

-

Product Catalog

112 Pages