Website:

Matec

Website:

Matec

Catalog excerpts

SLURRY DEWATERING THROUGH PRESSURE To obtain perfectly dried mud cakes, Matec filter press is the best technical/economical solution. Our machines use more pressure than those of our competitors, working up to 20 Bar. More pressure means greater results, both in terms of cake dryness and cycle time. Matec filter press guarantees: DRY CAKES The average residual moisture is 15%, but we can squeeze cakes to obtain 7-8% residual moisture. CLEAN WATER The water obtained from the dewatering is clean water ready to be reused or disposed of safely. 2 | dewatering The filter press can be applied to...

Open the catalog to page 2

THE FILTER PRESS Compliance with environmental laws has become important for plant owners in most countries. Cutting-edge technologies have been developed in the industrial wastewater and slurry treatment field. Matec technology complies with the latest environmental regulations, while maximizing the returns of the plant, through savings and earnings. That is what clients have been asking for. Matec offers four ranges of filter presses: ACQUAE, IGNIS, TERRAE, MAGNUM. Our machines can handle all kinds of capacities and flow rates, and are designed for heavy duty projects. Automation, top...

Open the catalog to page 3

WHAT MAKES MATEC THE BEST SOLUTION FOR YOUR BUSINESS Matec can exhibit over 10 years of exper- The faster the time for cake discharging The use of important brands does not only tise in the manufacturing of filtration and and for restarting the filtration, the more mean quality, it is also an important guaran- clarification machines. We started with filter productive is the machine. MATEC is the tee for the availability of components locally. presses for aggregates, which require more only company which uses the TT2 patented MATEC only uses top brands. Siemens and pressure, to become a...

Open the catalog to page 4

When the plates are held together in a unique pack, the corner outlets form individual manifolds which connect the drainage surface to the external pipes. The central hole from which the sludge is injected (less frequently there are feeding holes in the corners) creates a manifold which connects to the chambers of the filter pack. TT2 FAST The discharging time is a dead time in the productive cycle, so the faster is the opening the greater are the savings. TT2 Fast is the fastest opening system in the market. This system is installed on filter presses with more than 50 plates and...

Open the catalog to page 5

AAcqux 500x500 Specifications Acqu^ model 400x400 Specifications Acqu^ model 500x500 10 acqus 'The ton/h and m3/h data in the table above are calculated on a material specific weight of 1,85 and a 35 mm cake thickness. The ton/h and m3/h data in the table above are calculated on a material specific weight of 1,85 and a 35 mm cake thickness. acqus | 11

Open the catalog to page 6

acqus 'The ton/h and m3/h data in the table above are calculated on a material specific weight of 1,85 and a 35 mm cake thickness. The ton/h and m3/h data in the table above are calculated on a material specific weight of 1,85 and a 35 mm cake thickness. ignis 13

Open the catalog to page 7

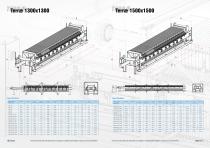

Chamber Volume (Liters) Capacity per cycle (Liters) *The ton/h and m3/h data in the table above are calculated on a material specific weight of 1,85 and a 35 mm cake thickness. Chamber Volume (Liters) Capacity per cycle (Liters)

Open the catalog to page 8

16 | terra 'The ton/h and m3/h data in the table above are calculated on a material specific weight of 1,85 and a 35 mm cake thickness. Specifications The ton/h and m3/h data in the table above are calculated on a material specific weight of 1,85 and a 35 mm cake thickness. terra | 17

Open the catalog to page 9

Magnum2000x2000 Specifications Terr^ model 1500x2000 Specifications Magnum model 2000x2000 18 | terra 'The ton/h and m3/h data in the table above are calculated on a material specific weight of 1,85 and a 35 mm cake thickness. The ton/h and m3/h data in the table above are calculated on a material specific weight of 1,85 and a 35 mm cake thickness. magnum | 19

Open the catalog to page 10

OPEN FILTRATE DESIGN HIGH THICKNESS STEEL ALLEN BRADLEY SIEMENS TECHNOLOGY m TO BE PERFI TURNKEY WATER TREATMlNT AND FILTER PRESSNO PERSON, NO . POLYMER, NO PROBLEMS! Turn Hard-To-Handle Sludge Into Easy-To-Handle Dry Cakes With The Matec Plate & Frame Press

Open the catalog to page 11

MATEC ACCESSORIES - FOR PERFECT RESULTS REAL WASHING The filter press can be equipped with an automatic washing system for plates and cloths. The system is composed by one valve and one system of pipes on the mud head side of the filter press, and discharging valves on every single plate. The feeding pump sends clean water to wash the residual mud. The sytem washes the plates 20 by 20. The frequency of the washing cycle is set through the operator panel. CORE BLOW The core blow system is a system conceived to clean out the central feeding residual liquid mud which remains in the diffusion...

Open the catalog to page 12

Standard Pumps FILTER PRESS FEEDING PUMPS The pump is the beating heart of the filter press and which one you choose will influence the performances of the plant, in terms of number of cycles and m3 of produced sludge per hour. The pump type is also responsible for the mud moisture percentage of the cakes. SINGLE CASE CENTRIFUGAL PUMP The centrifugal pump for the filter press feeding guarantees the maximum speed filling and a final mud cake with low residual moisture. It can be installed with double speed motors for an homogenous filling of the filter, with the first speed, and more compact...

Open the catalog to page 13

SILOS DEEP CONE - VERTICAL THICKENER The clarification process is essential to a wastewater treatment plant. Unlike the filtration carried out by the filter press, the clarification is a continuous process that separates water from the solid particles suspended into it. MUD SENSOR A pressure sensor can be placed on a membrane at the bottom of the cone of the silo. The discharging valve opens only when the required density is reached. The vertical decanters are based on the principle of static decantation and the natural precipitation of suspended solid particles. During decantation...

Open the catalog to page 14

Submersible Pumps Rubberized Pumps Vertical Pumps VALVES Silo decanters and piping for the measuring of lime in gang-saw can be equipped with automatic and manual valves. They have a special rubber sheath and can have one or two chambers. The automatic valves are all air-operated. SUBMERSIBLE PUMPS High resistant feeding pumps made of cast iron and special steels. They are used to pump waste water and sludge and ideal to be placed in deep pits, no needing any wall interventions. The motor is completely submersed and watertight. All pumps have seals which guarantee a longer life and are made...

Open the catalog to page 16All Matec catalogs and technical brochures

-

Marmi

22 Pages

-

Global

24 Pages

-

america

16 Pages

-

GENERAL CATALOG

28 Pages

-

CWR

16 Pages

-

Cube 100% Mobile

17 Pages

-

Major References In the world

24 Pages

-

Xgeneration

20 Pages

-

Matec Catalog

48 Pages