Website:

LINSINGER

Website:

LINSINGER

Group: Weingärtner

Catalog excerpts

LINSINGER Austria Shipbuilding Plates Bail Tank Segments Ship Profiles Submarine Hatches www.linsinger.com

Open the catalog to page 1

rivoiivurnrr Company Profile Company Prsentation Product Range Foundation: Employes: Headquater: Export: 1946 Linsinger Steyrerm驹hl 400 Employes Austria / Europe 98% worldwide SAWING-Technology Main Export Countries: Europe, Asia and Russia MILLING-Technology Highlights: 1985 First Plate Edge Milling Machine for Shipyard to Finland 1989 First Hatch Milling Machine for Submarines to Korea 1993 First Twin Table Plate Edge Machine to Korea 1999 First Profile Milling Machine for Shipbuilding to Denmark 2003 New Concept for Milling of Spherical Segments to Korea 2005 Largest Plate Edge Milling...

Open the catalog to page 2

f f\f Machines and Products Standard Machine Special Machines Plate Edge Milling Machine For Shipbuilding Plates Milling Machines for Ball Tank Ball Tank Segments Spherical Segments Profile Milling Machines Ship Profiles Accurate Welding Preparation Portable Hatch Milling Machines Submarine Hatches Multi Purpose Preparation 3

Open the catalog to page 3

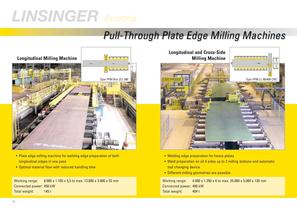

iivoiivurcM Pull-Through Plate Edge Milling Machines Longitudinal Milling Machine Longitudinal and Cross-Side Milling Machine Plate edge milling machine for welding edge prթparation of both longitudinal edges in one pass Optimal material flow with reduced handling time Working range: 8.000 x 1.100 x 5,5 to max. 13.800 x 3.600 x 52 mm Connected power: 450 kW Total weight: 145 t Օ Welding edge preparation for heavy plates Weld preparation on all 4 sides up to 2 milling stations and automatic tool changing device Օ Different milling geometries are possible Working range: 4.000 x 1.350 x 6...

Open the catalog to page 4

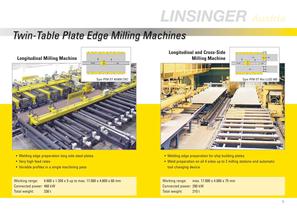

If If." Twin-Table Plate Edge Milling Machines Welding edge prթparation long side steel plates Welding edge prթparation for ship building plates Very high feed rates Օ Weld preparation on all 4 sides up to 2 milling stations and automatic Variable profiles in a single machining pass tool changing device Working range: 4.600 x 1.200 x 5 up to max. 17.000 x 4.600 x 60 mm Working range: max. 17.000 x 4.000 x 75 mm Connected power: 460 kW ^^^^^^H Connected power: 290 kW Total weight: 330 t Total weight: 210 t 5

Open the catalog to page 5

rivoiivurnrr MILLING-Technology Fast Milling LINSINGER Austria developed the so-called HF-milling system, utilizing circumferential cutter-heads. This system is also applied to this new Plate Edge Milling Machine. As most of the plates that are processed can show waviness, it is important that the milled chamfer be kept uniform and constant along the whole length of the plate. LINSINGER's inno-vative milling unit with copying technology fulfils this requirement. With the milling system from LINSINGER, very high processing speeds can be achieved. In addition, LINSINGER can process various...

Open the catalog to page 6

t fit. Why Linsinger? Your requirements A machine designed exactly to your requirements Օ Linsinger tooling service for ongoing availability Minimised down time for maximised productivity Օ Guaranteed service by experienced specialists 0und the *or/(f Our solutions Individual turnkey solutions Օ Continual tooling developments Higher cutting efficiency for lower tooling costs Օ Increased efficiency Linsinger's own experienced tooling engineers Օ Linsinger's highly qualified team for a professional service worldwide 7

Open the catalog to page 7

LINSINGER Austria LINSINGER Maschinenbau Ges.m.b.H A 4662 Steyrermiihl, Dr. Linsinger-Str. 24 Tel. +43 7613 88 40, Fax +43 7613 88 40 951 e-mail: maschinenbau@linsinger.com http://www.linsinger.com In tune with the times

Open the catalog to page 8