Website:

Klüber Lubrication

Website:

Klüber Lubrication

Group: Freudenberg

Catalog excerpts

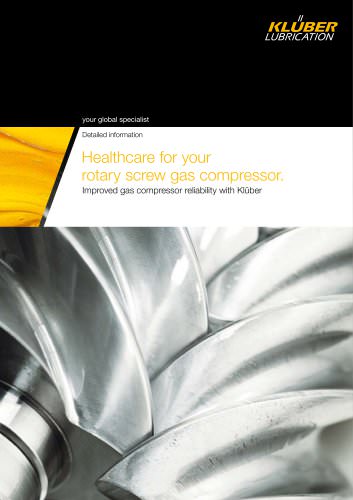

your global specialist Detailed information The right lubricant for each component. A selection of speciality lubricants for bearings, linear guides, gears, chains, screws, compressors and pneumatic applications

Open the catalog to page 1

The right lubricant for each component 3 The right lubricant for each component You need a lubricant - we've got it: for each industry, component size or any conceivable load on the lubrication point. We've created this brochure on the most frequently used components to show you the quick way to find the right lubricant for your requirements. The intention of this lubricant selection brochure This brochure is an overview providing you with comprehensive know-how gained from our more than 80 years of experience in the lubricants sector. The products presented in this brochure represent...

Open the catalog to page 2

Rolling bearings Special greases Selection criteria Upper service temperature approx. Lower service temperature approx. Low-temperature applications Low-noise applications Most important selection criterion Speciality lubricants from Klüber Lubrication Description / application examples –– Tried-and-tested long-term grease for rolling bearings subject to high temperatures –– Very good long-term stability –– Very good corrosion protection –– Approved and recommended by many manufacturers –– Tested and listed for use in the food-processing industry according to NSF H11) PFPE, ester PTFE,...

Open the catalog to page 3

Rolling bearings Special greases Selection criteria Upper service temperature approx. Lower service temperature approx. High-speed and spindle bearing applications High-load and heavy-duty applications 140 °C 284 °F Applications in the food & pharma industry Applications requiring electric conductivity Most important selection criterion Speciality lubricants from Klüber Lubrication Description / application examples synthetic hydrocarbon / ester –– Especially for spindle bearings with inclined or vertical mounting position, but also for horizontal shafts in machine tools synthetic...

Open the catalog to page 4

Plain bearings Special greases Max. surface pressure [N/mm²] High-temperature, long-term lubricating grease with largely neutral behaviour towards many materials (metals, plastics) Lifetime lubrication enables a significant reduction in lubrication quantities Alternative to Klüberlub BVH 71-461, suitable for higher ambient temperatures Extended relubrication intervals, also at high temperatures owing to its long-term stability The preferred lubricant option for plain bearings, offering long service life and relubrication intervals Suitable for universal standard applications Especially for...

Open the catalog to page 5

Plain bearings Special oils and dry lubricants Lubricating oils for hydrodynamic plain bearings: Application / requirement Speciality lubricants from Klüber Lubrication Viscosity depends on temperature and speed Tried-and-tested gear oil series compatible with conventional plain bearing metals Particular long-term resistance Viscosity depends on temperature and speed Long-term, reasonably priced compressor oil series compatible with conventional plain bearing metals Alternative: Klübersynth GH 6-…, if the required viscosity is not available in the Klüber Summit SH series Tried-and-tested...

Open the catalog to page 6

Linear guides Special oils and fluid greases Oil lubrication for continuous lubrication: Industry / requirements Linear type Speciality Lubricants from Klüber Lubrication General / increased corrosion protection Good compatibility with other lubricants; can also be used for initial lubrication Rolling motion guides CLP gear oil offering good corrosion- and wear protection. Viscosity to be selected according to speed. Klüberoil GEM 1-46 N is suitable for particularly low ambient temperatures CGLP slideway oil with good demulsifying behaviour towards cooling lubricants, tried-and-tested also...

Open the catalog to page 7

Linear guides Special greases Grease lubrication for extended relubrication intervals: Linear type Selection criterion Speciality lubricants from Klüber Lubrication Rolling motion guides, primarily with balls Lubricating grease, good adhesion and sealing effect Medium speed (corresponds to 15 to 60 m / min) Lubricating grease, good adhesion and sealing effect High speed (> 60 m / min) Lubricating grease, good adhesion and sealing effect Miniature guideway Fluid grease. NLGI 0 for easy application Roller screw drives Good lubricating capacities in linear contact Trapezoidal thread drives...

Open the catalog to page 8

Gears Special oils Gear type Spur, bevel, planetary and hypoid gears Service temperature range Performance parameters Upper service temperature, approx. Lower service temperature, approx. Energy saving potential Worm gear Speciality lubricants from Klüber Lubrication DIN 51 502, DIN 51517-3, AGMA 9005 designation Wear protection of rolling bearings Scuffing load capacity of gearing Micro-pitting resistance of gearing Elastomer compatibility Radial shaft seals Food & pharma Food & pharma Ecologically sensitive areas Optimum performance / enhanced benefit Improved performance / benefit...

Open the catalog to page 9

Chains Speciality lubricants Upper service temperature approx. Selection criteria Food-processing and pharmaceutical industries Special high-temperature chain oil based on polyglycol for chains in can lacquering lines; NSF H1-registered1) and ISO 21469-certified 1 000 °C 1 832 °F Note: above approx. 200 °C / 392 °F dry lubrication Solid lubricant suspension, e.g. for chains in burning, melting or annealing furnaces. Note: for applications at service temperatures above 250 °C / 482 °F 500 °C 932 °F Note: above approx. 200 °C / 392 °F dry lubrication High-temperature chain oil containing...

Open the catalog to page 10

Screws Special pastes and dry lubricants Service temperature range Screw material upper service temperature range approx. lower service temperature range approx. Speciality lubricants from Klüber Lubrication friction values for initial tightening2) special steel A 2-70 Approved acc. to VW-TL 52112 and Ford Tox No. 138624. Above 200 °C dry lubrication For screws and bolts subject to normal temperatures For use in agricultural, forestry and water resources industries Dispersion. A dry alternative to high-temperature screw pastes for cleaner handling Bonded coating for high pressure. Low...

Open the catalog to page 11All Klüber Lubrication catalogs and technical brochures

-

KlueberEfficiencySupport

7 Pages

-

Klübermatic lubricant dispensers

13 Pages

-

Driving with Klüber Lubrication.

15 Pages

-

Geared up for success.

32 Pages

-

All sprays at a glance

2 Pages

-

Bonded coatings

16 Pages

-

Automotive industry

16 Pages

-

Cement industry

2 Pages

-

Tribojournal edition 1 - 2011

32 Pages

-

Seaworthy

24 Pages

-

Pneumatics

24 Pages