Website:

Klüber Lubrication

Website:

Klüber Lubrication

Group: Freudenberg

Catalog excerpts

Lubricants … … for the food-processing industry Lubrication is our World

Open the catalog to page 1

Improve the Quality & Protect the Environment 3 Kliiber takes initiative 6 Kliiber Food Grade Lubricants 6 Taps, valves, fittings 14

Open the catalog to page 2

Improve the Quality & Protect the Environment A simple philosophy pays off twice Provide only top quality products and services and your customers will hold you in high esteem. Based on this philosophy, Klüber has been manufacturing speciality lubricants for almost 80 years. in this respect. The first company in Munich to pass the EC Eco Audit, Klüber actively pursues a global environmental management policy in line with the ISO 9001 quality management system. With more than 30 subsidiaries, 14 production plants and more than 1,700 employees worldwide, Klüber is your reliable partner in...

Open the catalog to page 3

Lubricants for the food-processing industry Lubricants for incidental food contact For decades Klüber has been developing and manufacturing special lubricants tailored to suit the requirements in the food-processing industry. Lubricants for technically unavoidable product contact1 have to: • comply with food regulations • be physiologically inert • be without taste or smell and • be internationally approved. Furthermore, lubricants for technically unavoidable product contact have to meet general technical requirements, i.e. • reduce friction and wear • protect against corrosion • dissipate...

Open the catalog to page 4

Based on the specified raw material lists, NSF registration is done in two categories: Speciality lubricant according to NSF H1: Suitable for an incidental, technically unavoidable contact with the food product. Speciality lubricant according to NSF H2: Suitable for use in the food-processing industry provided that a contact with the food product is absolutely impossible. Manufacture (constituents, quantity and purity) conforming strictly to FDA 21 CFR § 178.3570 5

Open the catalog to page 5

Klüber takes initiative Klüber working for a common goal As a manufacturer of H1 lubricants for technically unavoidable product contact, we accepted the challenge of meeting the requirements of the ISO 21469 standard for H1 lubricants. ISO 21469 determines hygiene requirements for the formulation, manufacture and use of H1 lubricants. The clean solution for high requirements: Klüber H1 lubricants NSF H1-registered and NSF ISO 21469-certified for more product responsibility! ISO 21469 Certified The NSF developed a certification procedure on the basis of ISO 21469, which includes the yearly...

Open the catalog to page 6

All-round lubrication engineering service The service designed to ensure optimum lubrication management systems to be delivered by careful consideration of both personnel and machines. Our service tool selection comprises: • Extensive technical consulting services provided locally by our application-engineering team. • Production sites specifically qualified for the manufacture of H1 food-grade lubricants. • We offer a special software for managing and monitoring your lubrication points. • Kosher certification of the production sites takes place once a year. • Used lubricant analyses ensure...

Open the catalog to page 7

Gears Product Base oil Service temperature range* [°C] ≈ ISO VG Density DIN 51 519 at 20 °C [g/ml] DIN 51 757 ≈ Selection criteria Klüberoil 4 UH1-150 N – 30 to 120 150 0.85 Klüberoil 4 UH1-220 N synth. hydrocarbon oil, ester oil – 30 to 120 220 0.85 Klüberoil 4 UH1-460 N synth. hydrocarbon oil, ester oil – 30 to 120 460 0.86 Klübersynth UH1 6-150 polyglycol oil – 35 to 160 150 1.05 Klübersynth UH1 6-220 polyglycol oil – 30 to 160 220 1.05 Klübersynth UH1 6-460 polyglycol oil – 30 to 160 460 1.05 Klüberoil GEM 1-150 N mineral oil – 5 to 100 150 0.85 Klüberoil GEM 1-220 N mineral oil – 5 to...

Open the catalog to page 8

Kinematic viscosity DIN 51 562 pt. 1 [mm2/s] at ≈ 40 °C 100 °C Viscosity index DIN ISO 2909 (VI) ≈ Pour point DIN ISO 3016 [°C] 150 19 150 ≤ – 30 220 26 150 ≤ – 30 460 47 150 28.5 > 210 < – 35 220 41 > 220 < – 35 460 73 > 240 < – 30 150 15 90 < – 10 220 19 90 < – 10 460 30 85 Wide service temperature range, good ageing and oxidation stability, good wear protection and loadcarrying capacity, good corrosion protection, neutral towards sealing materials and paints. Klüberoil 4 UH1-68 N … 1500 N-oils comply with CLP requirements DIN 51 517 T3; scuffing load stage > 12 in the FZG test, DIN 51...

Open the catalog to page 9

Rolling bearings Product Base oil/ thickener Service temperature range* [°C] ≈ Density at 20 °C [g/cm3] ≈ – 40 to 150 0.92 65 10 beige synth. hydrocarbon oil, ester oil/ Al complex soap – 45 to 120 0.90 30 6 white Klübersynth UH1 64-1302 synth. hydrocarbon oil, silicate – 10 to 150 0.99 1,300 100 beige BARRIERTA L 55/2 PFPE / PTFE – 40 to 260 1.96 420 40 white Klüberfood NH1 94-402 white oil/ calcium complex soap – 30 to 140 0.97 400 40 beige Selection criteria Lubricating grease for a wide service temperature range Compliant with NSF H1 Mineral-oil free Smooth running grease with good...

Open the catalog to page 10

Drop point DIN ISO 2176 [°C] none > 220 none not measurable ≥ 250 Speed factor** [n · dm] mm ϫ min–1 ≈ 500,000 800,000 50,000 300,000 – Worked Consist- Apparent Notes penetration ency dynamic DIN NLGI viscosity ISO 2137 grade KL viscosity [0.1 mm] DIN grade 51 818 265 to 295 310 to 340 265 to 295 2 1 2 L Good wear protection, good water resistance, high ageing and oxidation stability, good corrosion protection, good resistance to aggressive media. Also suitable for the lubrication of guide bars, lifting cylinders and joints. L Excellent low-temperature behaviour; good water resistance, good...

Open the catalog to page 11

Plain bearings/joints Product Base oil/ thickener Service temperature range* [°C] ≈ Density at 20 °C [g/cm3] ≈ – 40 to 120 0.92 150 22 beige – 45 to 120 1.13 200 75 white – 5 to 80 1.06 12 – colourlessyellowish – 35 to 120 0.92 210 20 amber Selection criteria Universal lubricating grease NSF H1 Synthetic Klübersynth UH1 14-151 synth. hydrocarbon oil/ Al complex soap Klüberpaste UH1 84-201 synth. hydrocarbon oil/ PTFE Klüberfood NH1 6-10 polyalkylene glycol oil White lubricating paste Compliant with NSF H1 Mineral-oil free, metal-free Base oil Colour viscosity DIN 51 562 pt. 1 [mm2/s] at ≈...

Open the catalog to page 12All Klüber Lubrication catalogs and technical brochures

-

KlueberEfficiencySupport

7 Pages

-

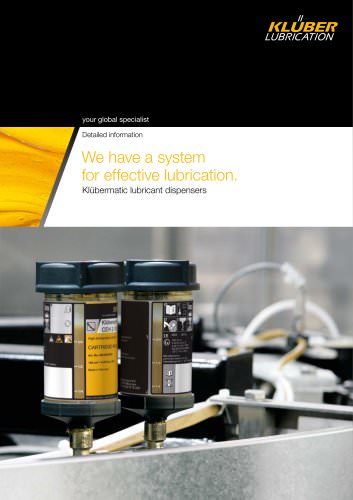

Klübermatic lubricant dispensers

13 Pages

-

Driving with Klüber Lubrication.

15 Pages

-

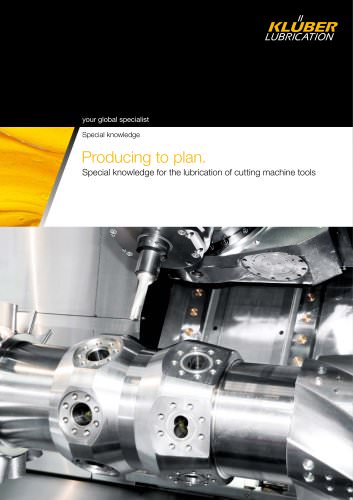

Geared up for success.

32 Pages

-

All sprays at a glance

2 Pages

-

Bonded coatings

16 Pages

-

Automotive industry

16 Pages

-

Cement industry

2 Pages

-

Tribojournal edition 1 - 2011

32 Pages

-

Seaworthy

24 Pages

-

Pneumatics

24 Pages