Website:

Klüber Lubrication

Website:

Klüber Lubrication

Group: Freudenberg

Catalog excerpts

your global specialist Industrial sector The recipe for your success. Speciality lubricants for the food-processing industry

Open the catalog to page 1

Reduce contamination risks, increase efficiency 3 Lubricating greases for rolling bearings, plain bearings and linear guides 4 Lubricating oils for gears and bearings 8 Lubricating greases for use in gearboxes and centralised lubricating systems 13 Lubricating oils for compressors and vacuum pumps 14 Lubrication of metal can seaming machines 19 Hydraulic and pneumatic lubricants 25 Products for mechanical seals, assembly and maintenance 26 Greases for valves and fittings 28 The right lubricant at the right place at the right time 30 Manufacturers of food...

Open the catalog to page 2

Lubricating greases for rolling bearings, plain bearings and linear guides In addition to their basic function of enabling machine movements, rolling bearings, plain bearings and linear guides used in the food industry need to perform satisfactorily when under attack from ambient media, such as water, steam or cleaning agents, or when exposed to high or low temperatures. The correct selection of the lubricating grease to cope with these conditions is crucial for lower maintenance costs and to avoid unplanned machine stops. The following table gives you an overview of H1 synthetic greases,...

Open the catalog to page 3

Friction torque and load-carrying capacity Changeover from industrial to H1 greases Grease miscibility Grease formulation has a very significant influence on friction torque and operating temperature. Additionally, the interaction between the thickener and the base oil when submitted to high loads can generate more torque and consequently greater energy consumption. FAG-FE8 (DIN 51 819) tests are performed on lubricants subjected to high loads. The test runs for 500 hours for greases. Loads applied can vary from 5 to 100 kN and speeds from 7.5 to 6,000 rpm with different ball and roller...

Open the catalog to page 4

Special solutions by Kluber Lubrication help you achieve the goals of higher revenue with increased food safety and an improved ecological footprint. Our special gear oils ensure long maintenance intervals, high efficiency and lasting component protection, even at the gear’s performance limits. The following Kluber Lubrication gear oils are manufactured with fully synthetic bases to achieve the highest performance. They are used and recommended by the largest gear manufacturers. Our specialists will recommend the right oil for your requirements. Together we can lower your maintenance costs,...

Open the catalog to page 5

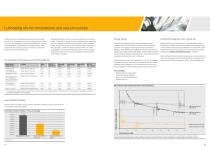

Bearings: Gear damage is often caused by high rolling bearing wear or premature fatigue of rolling bearings. The influence of high-performance gear oils on the wear behaviour of rolling bearings is measured in the FE8 wear test. Klüber Lubrication’s The performance capability of high-performance gear oils refers gear oils surpass this test’s minimum requirements for CLP oils, to all the gear components to be lubricated, i.e. gear teeth, rolling while also fulfilling the requirements of the FE8 lifetime test. bearings and radial shaft seals. Gear oils from Klüber Lubrication Consequently,...

Open the catalog to page 6

Lubricating greases for use in gearboxes and centralised lubricating systems Changeover from mineral to H1 PAO synthetic gear oil Kluberoil 4 UH1 N series Kluber Summit HySyn FG series Every changeover from mineral to synthetic food-grade oil should be performed with great care. It may not be enough to simply drain the used mineral oil and fill in the new synthetic oil. Older gears can be assumed to contain oil residues in the casing, the oil lines, etc., which might be dissolved by synthetic oils. If such residues are not removed, they may cause problems during operation. Oil lines and...

Open the catalog to page 7

Whether you are compressing ammonia (NH3) and carbon dioxide (CO2) for keeping food cool, or adding carbon dioxide (CO2) to your beverages, or even compressing air for blowing beverage bottles, compressors are key elements for food production and preserving, they are necessary in the daily life of every food processing plant. Mechanical failures can lead to serious production and revenue losses. Therefore, choosing the right compressor oil is vital. Have you ever imagined how lubricants can influence your operating costs? Or how lubricants can reduce your energy consumption? The lubricant...

Open the catalog to page 8

Screw-type Kluber Summit R 100 PAO 32 > 120 > 230 < -60 134117 refrigeration comoressors Kluber Summit R 150 PAO 46 > 130 > 230 < -55 150873 operating witfii Kluber Summit R 200 PAO 68 > 130 > 240 < -51 134122 compressors operating with ammonia and dry evaporation Refrigeration Kluber Summit RHT 68 Mineral 68 > 90 > 240 < -39 H2-144398 compressors operating with ammonia Kluber Summit Varnasolv Air compressor varnish cleaner Kluber Summit Varnasolv is a concentrated conditioner...

Open the catalog to page 9

Kluber Summit RHT 68 primarily focuses on ammonia, but can also be used with other refrigerants, for example R 22. It is a hydrotreated API group II oil, which means this product is very inert and will not react with ammonia. A very low content of sulphur results in no formation of sludge or varnish. Less evaporation loss = less oil consumption Kluber Summit R series, due to its very low pour point, is suitable for extremely low temperatures at the compressor evaporator (-60 °C, depending on the viscosity). It prevents the accumulation of frozen oil residues at the evaporator and maximises...

Open the catalog to page 10

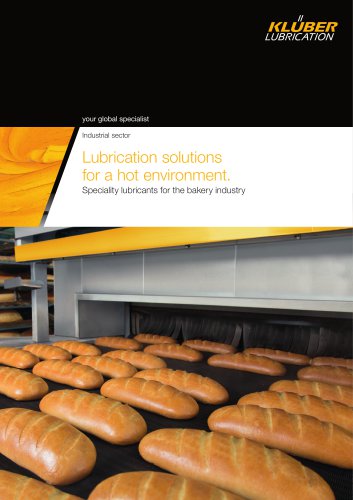

As a food producer, you are certain to be using chains in your production process for transferring power, driving or controlling machinery, lifting operations or, most commonly, transporting foodstuffs. In addition to the challenges resulting from the design of this machine element, you should consider the environment in which the chain is operating. Chains are often used in the food industry to drive conveyor systems in very hot areas (bakery ovens or beverage can manufacturing), very cold areas (freezing tunnels in the meat industry, ice cream production and other frozen foods) or through...

Open the catalog to page 11All Klüber Lubrication catalogs and technical brochures

-

KlueberEfficiencySupport

7 Pages

-

Klübermatic lubricant dispensers

13 Pages

-

Driving with Klüber Lubrication.

15 Pages

-

Geared up for success.

32 Pages

-

All sprays at a glance

2 Pages

-

Bonded coatings

16 Pages

-

Automotive industry

16 Pages

-

Cement industry

2 Pages

-

Tribojournal edition 1 - 2011

32 Pages

-

Seaworthy

24 Pages

-

Pneumatics

24 Pages