Website:

KAFO

Website:

KAFO

Catalog excerpts

No.16, Keya Rd., Daya Dist.,Taichung, Taiwan E-mail: kafo@kafo.com.tw http://www.kafo.com.tw

Open the catalog to page 1

Double Column Characteristic KAFO Customized Calculator New Generation Spindle Design 11 Long Nose Spindle Advantage 11 Double Column Tool Magazine 12 Spindle Torque Drawing Manual Head Machining Range 15 K/RV/KRV Series B/BMC Machine Spec List 19 B/BMC Tool Holder And Pull Stud B/BMC Machine Layout 26 O reserves the right to change or TAIWAN EXCELLENCE

Open the catalog to page 2

TAIWAN EXCELLENCE HOTA INDUSTRIAL MFG. CO., LTD. KAO FONG MACHINERY CO., LTD.

Open the catalog to page 3

^ Spindle assembly and adjustment In clean room with constant temperature and humidity. Assembly KAFO gear box and head unit in clean room. SCRAPPING - the difference from other brand, with KAFO line of machining centers, every component surface is finished by hand scraping for a proper fit, ensuring that the machine itself is geometrically correct and long lasting. The hand-scraping process is labor intensive and must be performed by skilled craftsman who are trained in the technique. Machine components must be placed then removed up to 5 times to confirm that the machine base in both D...

Open the catalog to page 4

DOUBLE COLUMN MACHINING CENTER New Generation Designed, Providing Best Rigidity Structure • Extended beam cross-section A • Widest column available in the market B • Largest spindle head support C • Thickest working table D • Biggest contact area for column support E • Minimum distance from spindle center to boxway F • Short spindle design G • Long distance between guideways H • Hydraulic counter balance system for Z-axis • Roller linear guideways from NSK/THK ( Japan ) or INA ( Germany) • Highest quality Meehanite casting • Thermo-symmetric box design base with high static and dynamic...

Open the catalog to page 5

DOUBLE COLUMN MACHINING CENTER High Rigidity Structure, High Positioning Accuracy ^ SUPERIOR BODY STRUCTURE chine bed, column, spindle head, cross slides and table are all analyzed and optimizes by FEM tests. This design assures high stability and rigidity of the machine, thus making it suitable for heavy-duty machining of all kinds of material. GEAR BOX OF THE THREE AXEST ballscrew with precision class P4 angular contact ball bearings. Gears, ground in accordance with Din level 5, provides good transmission efficiency and also gives the advantages of great transmission torque at low speed...

Open the catalog to page 6

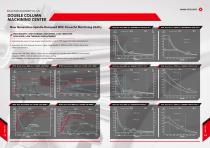

DOUBLE COLUMN MACHINING CENTER X HIGH SPEED AND PRECISION SPINDLE DESIGN • Using new generation 8000rpm direct driven spindle with high speed, high precision, high perfor- mance spindle motor, available high-quality rigid tapping. Without noise, backlash and vibration problems, standard accessories with spindle oil coolant system to control thermal displacement then getting best accuracy. Using 0100mm ceramic bearing with the spindle, after long time machining the vibration and thermal displacement could be controlled very well for keeping good tolerance of the dimension and High Torque &...

Open the catalog to page 7

DOUBLE COLUMN MACHINING CENTER New Generation Spindle Designed With Powerful Machining Ability - HIGH RIGIDITY, HIGH TORQUE, HIGH SPEED, LOW VIBRATION X LOW NOISE, LOW THERMAL DISPLACEMENT • Upgrading the output torque of gear head spindle (which is 10% bigger than other manufacturer) • Upgrading the main bearing diameter of gear head spindle to 100mm (which is 10mm above than other manufacturer) Strong motor 22k/26k ( 35HP ) is driven by two step gear box, spindle speed 6000rpm and powerful torque to 728Nm, which is most suitable for heavy cutting. Also available with roller type bearing...

Open the catalog to page 8

DOUBLE COLUMN MACHINING CENTER Attached Milling Head Design Manual 30° Angle Milling Head Manual Universal Head Manual 90° Angle Milling Head Manual Extension Head

Open the catalog to page 9

TAIWAN EXCELLENCE DOUBLE COLUMN MACHINING CENTER B/BMC SERIES

Open the catalog to page 10

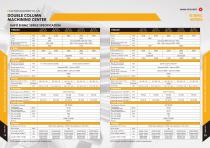

DOUBLE COLUMN MACHINING CENTER KAFO B/BMC SERIES SPECIFICATION KAFO reserves the right to change or modify the specification.

Open the catalog to page 11

DOUBLE COLUMN MACHINING CENTER KAFO B/BMC SERIES SPECIFICATION KAFO reserves the right to change or modify the specification.

Open the catalog to page 12

DOUBLE COLUMN MACHINING CENTER KAFO B/BMC SERIES SPECIFICATION

Open the catalog to page 13

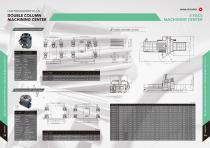

DOUBLE COLUMN MACHINING CENTER Tool Holder & Pull Stud V-Flange CAT-50 + V-Flange CAT-50 Tooling Dim. (CTS) TAIWAN EXCELLENCE MACHINE LAYOUT

Open the catalog to page 14

DOUBLE COLUMN MACHINING CENTER Greater 5-face Machining Performance Could Be Satisfied Customer's Muti-processing Requirements. This series with special designed, with strongest structure, greater rigidity body, using the vertical and horizontal head and tools, automatic exchange, take high rigidity gear box vertical and horizontal spindle, heavy cutting, processing high efficiency, precision machining parts with good quality and accuracy. After setting the workpiece, 5-face could be automatic completion of the processing This product is especially suitable for the manufacture of large...

Open the catalog to page 15

DOUBLE COLUMN MACHINING CENTER TAIWAN EXCELLENCE K SERIES AND RV SERIES: SIMPLE AND CONVENIENT HEAD CHANGING UNIT 1 . Optional automatic head change. 2 . Optional auto tool changer ( max.0215mm, length 400mm ). 3 . Angle milling head has undamped hydraulic cylinder, tool can be changed at any position. 4 . Unique and simple head changing unit doesn't occupy working space. 5 . Head changing unit has enclosure guards to protect against dirt and chips.

Open the catalog to page 16

DOUBLE COLUMN MACHINING CENTER KAFO K/KMC SERIES SPECIFICATION KAFO reserves the right to change or modify the specification.

Open the catalog to page 17

DOUBLE COLUMN MACHINING CENTER KAFO K/KMC SERIES SPECIFICATION KAFO reserves the right to change or modify the specification.

Open the catalog to page 18

DOUBLE COLUMN MACHINING CENTER KAFO Automatic Universal Head

Open the catalog to page 19

DOUBLE COLUMN MACHINING CENTER KAFO RV SERIES SPECIFICATION KAFO reserves the right to change or modify the specification.

Open the catalog to page 20

DOUBLE COLUMN MACHINING CENTER TOOL HOLDER & PULL STUD

Open the catalog to page 21

MOVING CROSS RAIL DOUBLE COLUMN MACHINING CENTER • Three axes travel (X:8200, Y:3700, Z:900mm ) is bigger than other manufacturer. • Three axes rapid speed with cooling system through ballscrew ( X:10, Y:20, Z:20m/min ) which is faster than other manufacturer. • W axis travel standard : 1000mm, option : 1700mm • Horizontal spindle speed : 3500rpm, which is faster than other manufacturer. • Attached head changer and head storage swivel shelf module could be chosen for saving space. weight balance operation (option ). Automatic attached head change X, Y and Z axes ballscrew with cooling...

Open the catalog to page 22All KAFO catalogs and technical brochures

-

vertical machining center

18 Pages

-

CV-6 Vertical Machining Center

1 Pages